By Jessica Franchuk

The role of every roof is to protect the building and its contents from exterior elements and threats. Rain, wind, hail, heat, sun exposure, and extreme cold can all wreak havoc on a structure, so over the years, standards have been created to ensure the best roofs are put on with the best practices.

One organization aiding in the creation of such standards and practices is the Roofing Industry Committee on Weather Issues (RICOWI). Their reports greatly affect the industry, with the Metal Construction Association (MCA) relying on RICOWI reports and other research to fulfill its mission of promoting the use of metal in the building envelope through marketing, education, and action on public policies that affect metal’s use.

RICOWI: A History

According to the RICOWI website (www.ricowi.com), the Roofing Industry Committee on Wind Issues was established in 1990 as a nonprofit organization to identify and address important technical issues related to the cause of wind damage. The organization’s vision statement is: To be the leading collaborative roofing research and educational forum where sound science and practice are forged.

The primary technical issues RICOWI addresses are: dynamic testing of roof systems; the importance of sample size for tests; the role of wind tunnels and air retarders; the need for acceptable procedures for ballasted systems; field data and response team reports; and a general lack of communication within the roofing industry as to what the problems are, what is being done and should be done to alleviate them, and how effectively information is transferred within the roofing industry and to others in the building community.

David L. Roodvoets, Owner and Principal Consultant of DLR Consultants, shared a timeline of the organization’s evolution:

1989: Hurricane Hugo and other storms awakened an awareness of wind issues in the roofing industry. Most roofing industry technical representatives gathered at Oak Ridge National Laboratory in Oak Ridge, Tennessee. These representatives formed several study groups, which led to the formation of two continuing organizations: RICOWI and SIGDERS (Special Interest Group on Dynamic Evaluation of Roofing Systems).

RICOWI started as a small group of people with only one representative from the technical personnel of most of the roofing industry’s associations. Discussions were primarily about the building codes and how they were not very helpful in adapting to the best science, especially wind design.

1992 to 1996: Following Hurricane Andrew in 1992, the information in most roofing press was biased by its source, creating a strong belief by members of RICOWI that there should be an unbiased source for post-windstorm information. This resulted in developing a wind investigation program that was presented at Oak Ridge in 1996 to about 150 participants. This was a very thorough program involving wind science, photographic techniques, and a database. Many of the participants joined as investigation team members and were fully trained and ready to begin investigations.

In 1996, RICOWI was incorporated as a nonprofit corporation devoted to research and education on wind issues. After a review of the need for similar education and research in the areas of hail, energy efficiency, and durability effects,fthe organization’s objectives were broadened in 1999 to include other weather topics, and “Wind” in RICOWI’s name was changed to “Weather” to reflect the expanded scope.

2004: Until this year, there were no hurricanes that reached a populated area of the U.S. and met the RICOWI investigation criteria (sustained wind speeds of 95 mph or greater at landfall in the continental U.S., as well as demonstrated significant damage to populated areas). Hurricane Charley was the first to hit as a category 4 storm with winds exceeding 140 mph, and RICOWI deployed about 40 participants to this investigation. Three more major hurricanes hit Florida in 2004, and RICOWI re-deployed to investigate the damage from category 3 Hurricane Ivan.

While waiting for qualifying hurricanes for long periods of time, RICOWI took on the investigations of hailstorms, with the first investigation being the Oklahoma Storm in 2004.

2005 to Present: RICOWI has deployed teams to investigate damage after Hurricane Katrina (2005), Hurricane Ike (2008), Hurricane Irma (2017), and Hurricane Michael (2018).

Investigation Programs and Goals

RICOWI’s website states three goals in its mission statement:

1. Encourage and coordinate research to provide a more knowledgeable information base of roof issues including wind, hail, energy efficiency, and durability effects;

2. Accelerate the establishment of new or improved industry consensus standard practices for weather design and testing where they are recognized as needed; and

3. Improve the understanding of roof weather concepts and issues within the building community in general.

To complete its goals, RICOWI has implemented two strategic investigation programs: the Wind Investigation Program (WIP) and the Hail Investigation Program (HIP). The purpose of these programs is to investigate the field performance of roofing assemblies after major hurricane and hailstorm events, to factually describe roof assembly performance and modes of damage, and to formally report the results for substantiated hurricane/hail events.

The data collected provides unbiased detailed information on the wind and hail resistance of low-slope and steep-slope roofing systems from credible investigative teams. The goal is a greater industry understanding of what causes roofs to perform or fail in severe wind and hail events, leading to overall improvements in roof system durability, the reduction of waste generation from reroofing activities, and a reduction in insurance losses, resulting in lower overall costs for the public.

RICOWI’s reports and multimedia presentations document roofing systems that fail or survive major weather events and provide educational materials for roofing professionals to design wind- and hail-resistant roofing systems. All collected data is intended to improve building codes and roof system design, and educate the industry and the public.

Data Collection and Reports

During a storm that would qualify as a significant weather event and meets RICOWI’s criteria, the committee chairs and Executive Director Jordan Lemke discuss if a team will be deployed. According to Lemke, the Hail Investigation Program and Wind Investigation Program are RICOWI’s most popular committees, and any member can volunteer to be a part of a deployment team. “We almost never have any trouble finding people to be a part of these committees,” Lemke shared.

After the decision to deploy is made, committee members are asked who is available to go on the investigation. In general, the committee chair and co-chair will deploy, along with others from the committee who are available. Investigators are provided information on damage modes, gathering and recording information, and safety training.

Each team has four positions: report writer, photographer, data recorder, and sample collector (in some instances, positions are combined). All team members act as observers, combining their expertise and observations to maximize the data obtained. In addition to manufacturing members, each team is balanced by including members of the insurance industry, consulting firms, or other non-manufacturer associations.

Clearance letters are requested from the investigation site cities, and local law enforcement officials are notified. As soon as the area is deemed safe by authorities, the team travels to the area and begins the investigation.

While it depends on the extent of the damage and how long it takes to gather info, final reports are typically published within a month or two. These reports are available to the public at no cost on the RICOWI website.

Weather and Metal Roofing

Any experienced metal roofing professional knows the obvious weather culprits that can inflict damage on metal roofs: high winds, impacts (hail and/or debris), and rain/moisture. Other not-so-obvious offenders include: wildfires, freeze/thaw cycles, salt spray, and UV exposure.

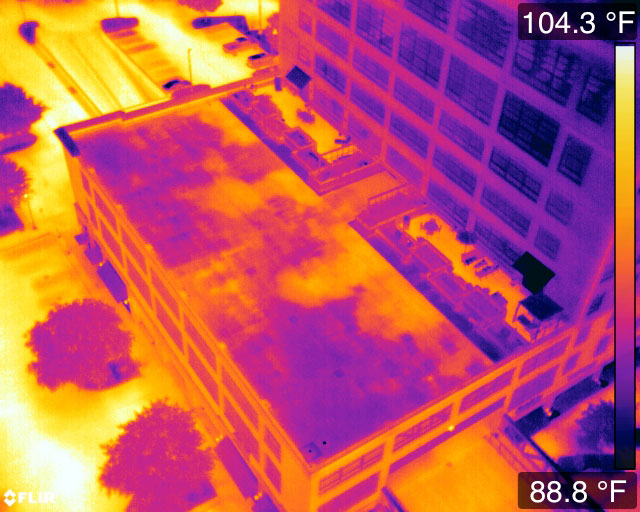

Bob Zabcik, Technical Director for the Metal Construction Association, said: “I would add thermal expansion/contraction and solar heat gain to that list. It’s important to understand which aspects of system design each of these items impact. In corrosive environments, it’s coating selection, obviously, but proper flashing and trim is also very important. In wind-prone areas, this is heavily dependent on connection strength and fastener selection. In snow country, rigidity and underlying framing strength is key.

“In mid-country environments, thermal expansion and contraction must be carefully analyzed and accounted for. Even color selection can have an impact on the energy efficiency of a climate-controlled building due to the radiative properties. The most successful projects are the ones that appropriately consider the relevant aspects unique to the site.”

Each region of the U.S. holds its own unique weather challenges for metal roofing, calling for special considerations during install. Roodvoets added: “Most metal roofing contractors in the North are aware that ice damming and snow slippage can be a problem and design for it. Snow and ice can be a significant issue with metal roofs over entrances. The slope of the roof over an entrance should be to the sides, away from where people walk, if possible. There are metal roofs that slope the wrong way in the town where I live and the building owners [have to] totally close off the entrance in the winter.

“Hail, especially in Texas and Oklahoma, can be larger than 2″ in diameter; that size hail will destroy many roofing systems. In most cases, metal roofs will remain watertight, but will be severely dented. Being near salt water can accelerate the deterioration of metal and especially fasteners; this can be a problem as far as 15 miles from the coast. This calls for treated metal and fasteners, and some limit on the life of the roof that is not seen where there is no salt spray.

“All roof types with potential corrosion from salt spray, acid rain, or treated wood need corrosion-resistant fasteners. The building codes can be strengthened in this area.”

While weather and climate are certainly real concerns in the lifespan of a metal roof, Zabcik said: “The fact of the matter is performance is never only based on climate and weather. Again, it is all based on having an appropriate system design that has considered the demands of the project location and has been properly installed by a trained person. Remember, the point of system design is to leverage the inherent strengths and mitigate the inherent weaknesses of the materials being chosen. This is true for all roofing systems, but at the MCA and MRA, we firmly believe metal is the most adaptable material available, and that’s the most important thing.

RICOWI and the MRA and MCA

The Metal Construction Association (MCA) is a trade association of manufacturers of metal building envelope components and related equipment, ancillary materials, and contractors. The Metal Roofing Alliance (MRA) is the leading voice for companies and professionals involved in the residential metal roofing industry.

While RICOWI is a separate entity formed from various consortiums, trade associations, insurance consultants, and other interested parties, “The MCA is an active participant in RICOWI. The MRA is more focused on marketing and education to the homeowner and as such, does not directly participate in RICOWI. However, several MRA members do participate in RICOWI through their MCA membership,” shared Zabcik.

According to Zabcik, the MCA and MRA depend very strongly on RICOWI and the Federal Emergency Management Agency (FEMA) for real-world observation aspects, and it is very common to have multiple MCA and MRA members on a RICOWI inspection team. This enables the organizations to see firsthand how metal responds to extreme weather events as well as actively participate in the post-event analysis. The reports produced by RICOWI help the MCA and MRA to understand the inherent strength in metal as well as teach new things to do to leverage those strengths. Zabcik added, “We also have strong partnerships with sister trade associations that have enabled us to get other perspectives. Having this feedback loop built into our organization has really helped us make the industry healthier and stronger.”

The Evolution of Metal Roofing

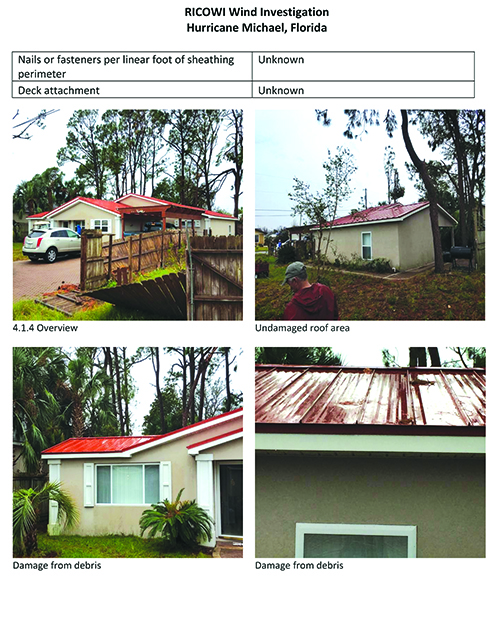

A page from the 2018 Hurricane Michael RICOWI report, showing very little damage to this bank’s structural standing seam roof.

Reports and findings are well and good, but only if the associated trade reacts and responds to them. Zabcik noted: “Metal cladding is like any other product in the marketplace. It must evolve and improve to meet the ever-changing demands made on it. This impacts roofing materials, coil finishes, codes, and then some. The key thing to understand is a metal roof is a system, not a component. The system is only as strong as the weakest component involved. Understanding the system behavior is critical and this can only be done through research.”

Zabcik went on to list key improvements to this area of the metal roofing industry: coatings, especially paint systems, have become exponentially more durable in the last 20 years, enabling the underlying materials to stay strong and help overall resilience; sealants, like paints, have benefitted from technological advancements and maintain their properties much longer; ancillary materials such as clips, fasteners, closures, and even trim have been tested and developed continuously and boost overall system strength and durability; equipment such as seamers, crimpers, field applicators, screw guns, etc., have benefitted from technological improvements, and achieve reproducible, reliable results; and codes have become more precise, almost surgical, in their requirements for system design. This has been primarily due to the research efforts of the MCA and their sister associations as well as through the efforts of RICOWI.

Finally, and most importantly, he continued, “Education and implementation of best practices through online resources have greatly aided the installer. After all, the best system in the world is only as good as its installation. Metal roofing installers all over the world have amazing, effective techniques that can be shared across the industry using the MCA and MRA channels.”

Roodvoets shared his thoughts on this, specifically related to 2018’s Hurricane Michael: “Metal roofing, like all roofing systems, is very dependent on design and installation. Several buildings with metal roofs in Hurricane Michael had only superficial damage, with the weathertight integrity intact. These covered most metal roof types such as structural standing seam, architectural standing seam, and through-fastened systems. There was, however, some total destruction of some metal buildings, and large roof failures. Some of the issues were primarily related to building wall failure that allowed severe pressurization of the building and roof. These buildings may not have been designed for 140 mph winds, as it was not required by code.”

He continued, noting what they’ve seen regarding roof types and weather: “There is no best. As stated earlier, all systems are dependent on design and installation. Metal roofs have done well, so have asphalt shingles, single-ply roofs, spray foam, BUR, cedar, etc. There have been some serious problems with all types, and few roofs are designed for winds greater than 140 mph.”

Still, these storm reports are vital for providing information to the industry as a whole. And “several proponents of code changes have used data from hurricane reports in their justification for building code changes with the International Code Council (ICC). The overall knowledge gained has strengthened the codes and kept some bad ideas out,” said Roodvoets.

The Future of RICOWI

While RICOWI has historically focused its efforts on wind/hurricane and hail damage, there is the potential of expanding their repertoire in coming years. Lemke indicated, “There has been talk recently of expanding into other weather-related events such as fire and tornadoes. Hopefully with the expansion into different areas like fire and tornado, we can continue to make a difference in the industry.”