By Ray Smith, Managing Director, AppliCad Software

The construction industry has long been known for its massive amount of waste as a percentage of the cost of a job, let alone how much ‘stuff’ ends up in landfill. Apart from the massive waste of valuable resources, there is also the additional cost of transporting this waste to its final resting place.

Perhaps one of the most motivating factors to address this issue in today’s climate is the extraordinary price rises that the construction industry has experienced in the past year or two. I am aware of many components in the roofing sector more than doubling in retail price in just 18 months! These increases are often difficult to pass on, especially if fixed price delivery of a property has been agreed to, and even if the price is not fixed, waste is profit margin that is going out the back door.

Complete

One way to address this in metal roofing, at least in part, is to reduce the amount of material that is not used to cover the roof – instead of trashing the offcuts from complex hip and valley roof structures, use them elsewhere on the roof! A method that has been in wide use for many years is what roofers in New Zealand call ‘Blocking’. This is a technique that is employed by experienced installers that reduces waste from a metal roof to almost zero.

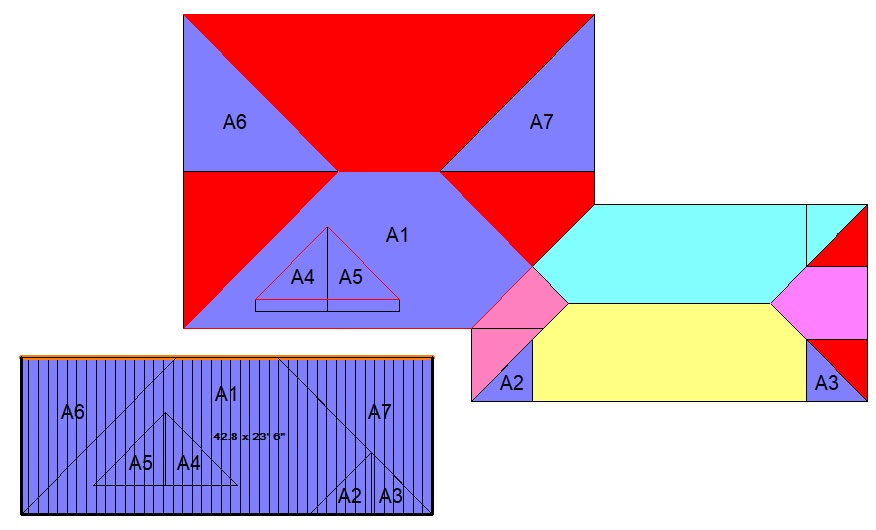

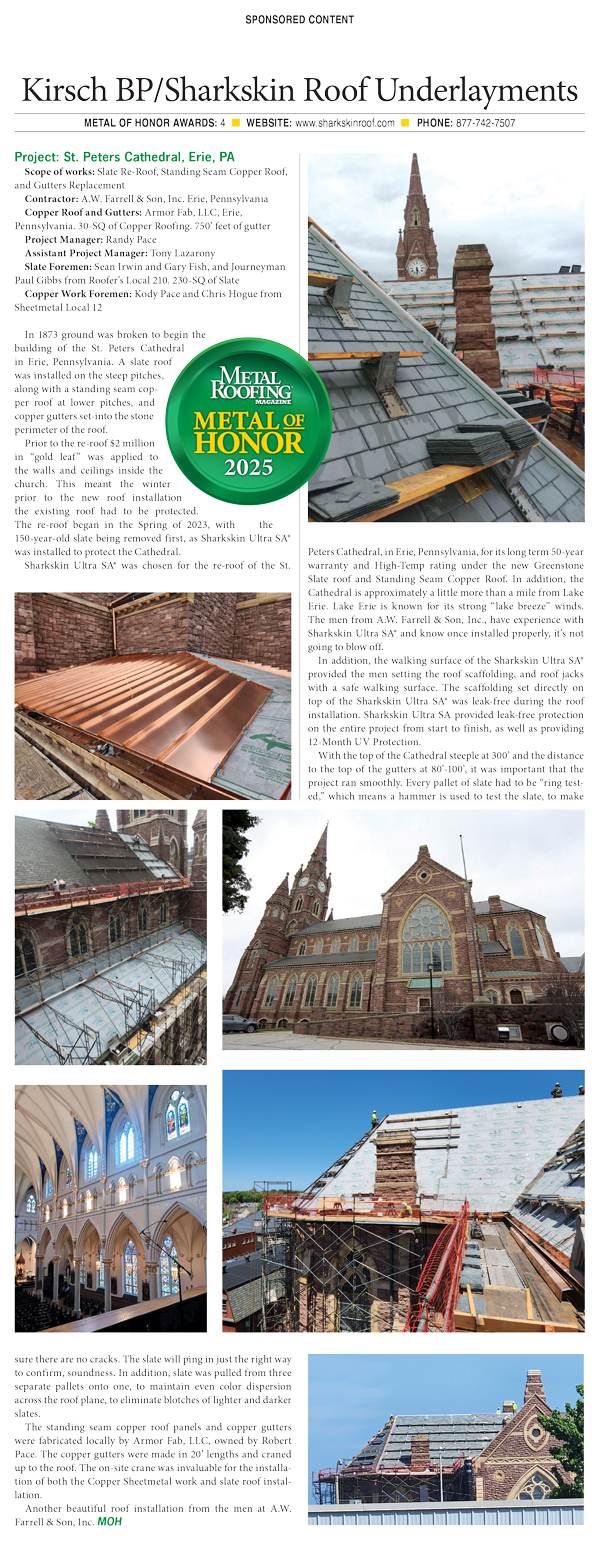

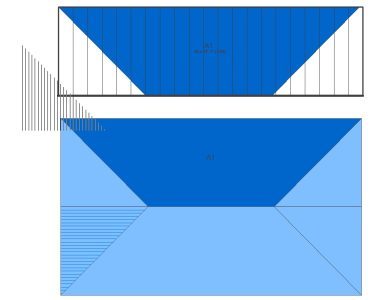

The offcut on full length panel on a hip end is flipped into the opposite hip – one cut, two panels, no waste! (Figure 1.)

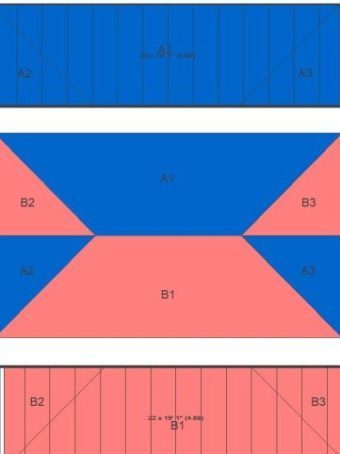

This technique has been further developed in the Roof Wizard software in a process we call ‘Block-Cut’. It results in efficient installation, reduced waste and improved profit. (See Figure 2.)

In this example, the only waste is the strip that is required because the roof is not an exact multiple of the panel width. The process is extrapolated across larger, and more complex roof shapes with the same result. We typically reduce waste from maybe 10-15% to less than 5% AND the installers get a map showing how the panels must be installed to achieve the desired result, thus reducing installation errors and further improving on site safety and efficiency.

It must be said that this does not suit all panel types. An exception to this would be narrow standing seam panels where the fabrication of the hem typically messes up the end such that any offcut is rendered useless. Besides that, the offcut is a very small percentage of the panel area as the panels are typically very narrow, say 16”. Block cut works exceptionally well for wide format panels such as Ag Panel, 5V, corrugated or ‘KlipLok’ – panels between 24” and 36” wide where the offcut is a more significant percentage.

Once the ‘Block-Cut’ layout is complete, the installation guide is produced, the cutting list is absolutely accurate, and supplier order forms are printed off.

The ‘Block-Cut’ process is one of the many standard functions in the Roof Wizard software that are designed to improve accuracy in estimating and improve the profit in your business. The saving on material costs are on average 10-15% on these jobs, and that goes straight to your bottom line as well as mitigating the effects of constant price rises.

Do the best job you can for yourself and your customer by investing a bit of time in the systems that help you. It is a very good investment for the long term and means that everyone in your team gets the benefit of the combined experience of you and your field crews.

You can count on a profitable job because you accounted for everything at the estimation/quoting stage. MR