By By Dripstop®/Freudenberg

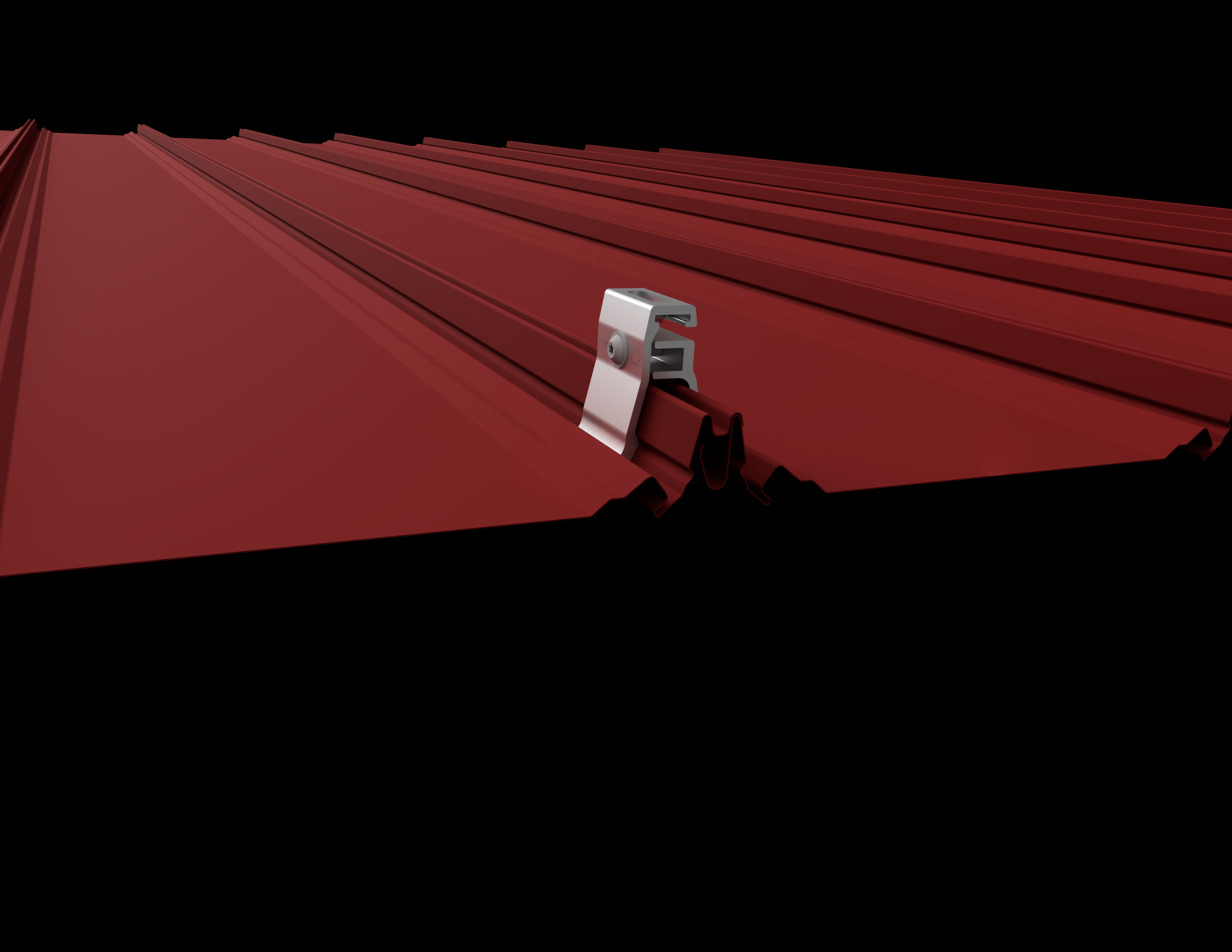

As residential metal roofs become increasingly more practical, more economical, and more attractive, their popularity is naturally growing as well. As we travel to different regions of the country, we see a variety of panel types and profiles on all styles and sizes of homes. We have also learned there are any number of different methods and applications in place across those regions. Several homeowners are choosing to retrofit their existing asphalt-shingled roofs with metal panels, especially when a complete tear-off is not an option for whatever reason.

We have learned there are different approaches to retrofitting as well. Some roofers opt to use wood furring strips to raise the metal up off the asphalt shingles, then screw the metal into those furring strips. There are numerous benefits to this approach, but it usually comes with an additional cost for the materials and labor.

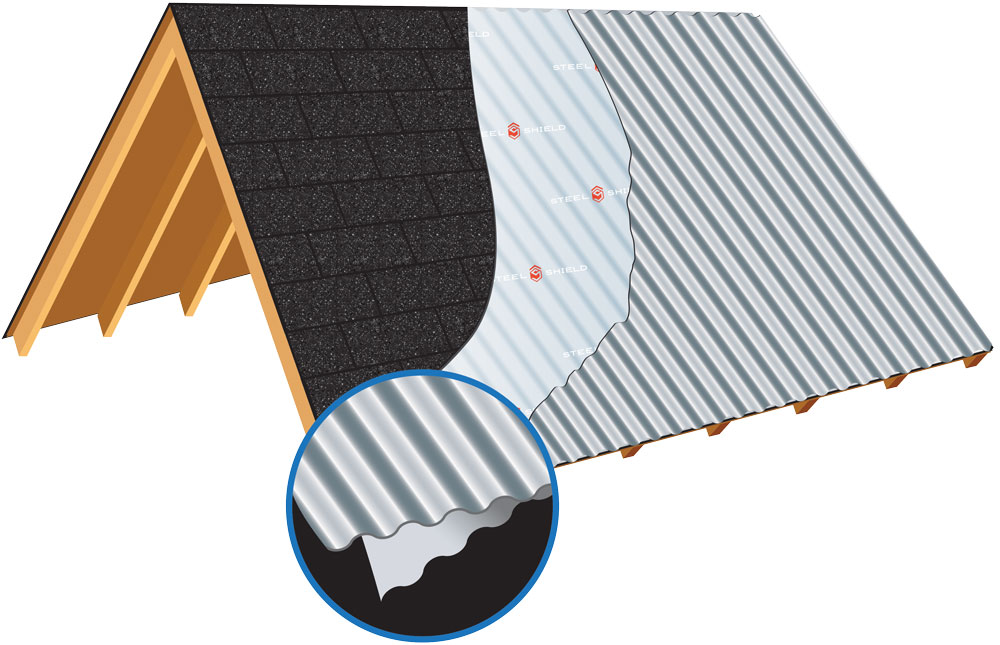

Others choose an even more economical way to install metal, screwing the panel directly through the shingle. However, since metal expands and contracts with temperature changes, the shingles can etch the underside of the metal panel if it’s not protected. Historically, roofing paper, felt, synthetics, and even bubble insulation have been tacked down and used as protection for the metal panels.

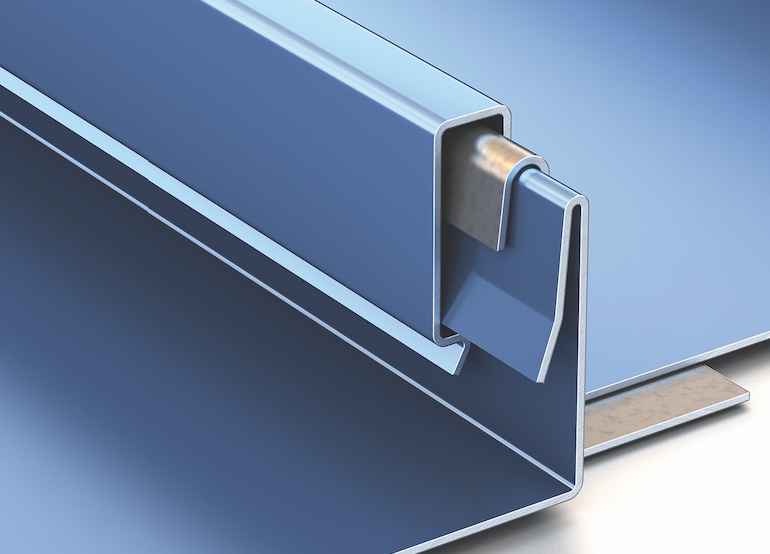

Steel Shield was created for the specific purpose of protecting the underside of metal roofing panels from abrasion. Freudenberg offers Dripstop®, which is a solution for controlling condensation on metal panels. It is a factory-applied felt membrane that captures moisture overnight and is primarily used in uninsulated metal buildings.

One of the unique qualities of Dripstop® is its exceptional durability and wear-and-tear resistance. Because of this, it wasn’t long before roofing contractors started using the product to protect metal panels from scratches caused by expansion and contraction. It saved time and money, since it does not require any labor to install. However, Dripstop® was designed for use on open purlins or trusses, where air movement will evaporate the condensation — not the case when metal is fastened directly to the shingles.

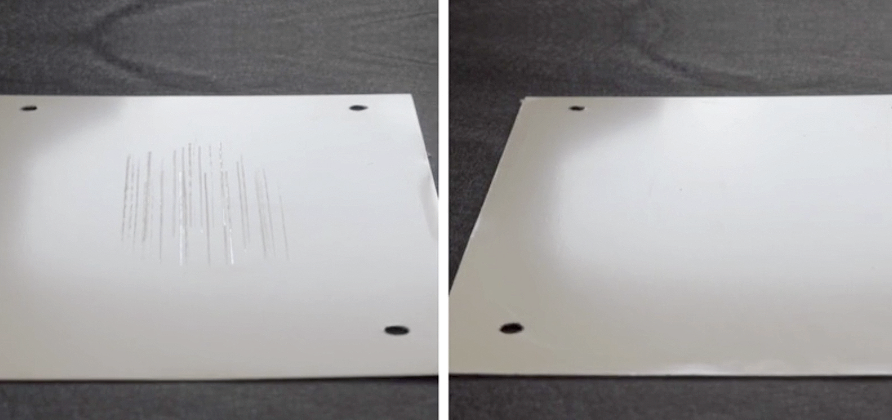

Therefore, the company invented Steel Shield for applications when panels are affixed directly to asphalt shingles. It is an abrasion-protection, factory-installed product that is just as durable as Dripstop®, but is designed to not hold water. Since it also shows up on the jobsite already on the metal and ready to install, there is no labor or time needed for its installation.

When a brand-new roof or complete tear-off is not in the cards, retrofitting an existing shingled roof with metal panels is a great option. MR