By Mark Robins

A metal roof retrofit is a metal roof repair process in which the existing metal on a building or structure is left in place and recovered or overlaid with another roof. Metal roof overlays are quick and easy to install compared to removing and replacing metal roofing and insulation on a building. Metal roof retrofit projects finish faster and buildings dry sooner in a much safer way.

“Retrofitting an existing metal roof is not complicated or hard to permit,” said Dale Nelson, president of Roof Hugger Inc. “It is actually easier than new construction in many ways since you can work off the old roof and are not walking on open purlins. It is non-invasive and customer friendly since you do not have to remove the old roof and expose the building to the weather. You will have to meet the current code requirements but if you work with a company like Roof Hugger they will do the preliminary design estimate that includes engineered framing plans to meet the code requirements based on the building and the new roof.”

Pat Thostenson, regional sales manager, commercial roof & wall, MBCI said besides the obvious benefits of retrofitting metal roofs, “[Retrofit] systems allow you to change the roof geometry of the structure which can completely update the structure’s aesthetic appearance and/or completely remove problems the current roof slope or geometry may be enabling.”

Understanding Retrofitting

What do builders need to know about retrofitting metal roofs with a metal roof? Charlie Smith, national recover manager at McElroy Metal, said, “The main thing builders need to learn is that at least half of the time, it is better to retrofit a new roof over the existing than remove and replace the existing roof. Consequently, step one of any reroofing project should focus on this decision.”

Smith cited several factors that deserve consideration:

• The amount of disruption the owner can tolerate

• The capacity of the existing structure

• If the existing roof contributes to the structural integrity of the building

• The appearance of the underside of the roof

• Whether the owner wants to bring his building up the current energy code

• If there are conditions that limit the height of any roof that may be added on top

• What the existing metal roof is attached to

• How it is attached to the deck or structure

• If the existing roof is exposed fastener or a standing seam

• If it’s a standing seam they need to know is it installed with high-floating or low-floating clips

• Understand that if the existing roof is on a steel deck or a wood deck, options for recovering are different than if the existing roof is installed on open purlins or bar joists.

Nelson explained that there are three basic things to remember when doing a metal-over-metal retrofit:

Dimensions and sizes.

The typical metal-over-metal roof retrofit project is done on an existing commercial or industrial building that has open framing 4’ to 5’ o.c. The first thing to understand is that 1” to 1-1/2” snap-seam or mechanically seamed residential panels cannot be used on a commercial project; they are not strong enough to span over open framing. Structural through-fastened panels 1-1/4” to 1-3/4” and commercial mechanically seamed panels 1-3/4” to 3” ribs can span from 4’ up to 6’ without additional support.

Building codes.

The building codes have changed dramatically over the past 25 years since the building being retrofitting was originally built. This means the existing purlin/joist spacing that worked then may not be adequate today. Consult with an engineer on your project to determine the correct spacing for the framing members to meet today’s standards. During the preliminary quoting of the project, consult with a reputable retrofit framing manufacturer for a design estimate or at a minimum get a “clip analysis” from your panel supplier. Keep in mind different panels will have different framing requirements. Stronger panels will need less framing, weaker panels more.

Existing roof.

Take note of where and why the existing roof is having problems: Is the roof at the end of its useful life or is the roof leaking and if so why? Don’t repeat the same mistakes. Retrofitting will allow you to remove some roof steps, relocate or eliminate roof penetrations and to increase the amount of roof insulation, improving the thermal efficiency of the building.

James Hazen, national roofing sales manager at Englert Inc. said builders should, “possess a comprehensive understanding of various critical metal roof retrofit factors. First and foremost, they should ascertain the specific design loads and potential snow loads applicable to the geographical location in which the project is situated. Additionally, a thorough assessment of the structural capabilities of the project is imperative, necessitating consultation with a professional design engineer to ensure compliance with safety and performance standards. Builders should be knowledgeable about such remediation options and be adept at determining their applicability to the specific project requirements.”

Roof Retrofit Installation Insight

There are several different ways to retrofit an existing metal roof. Nelson cites the following methods:

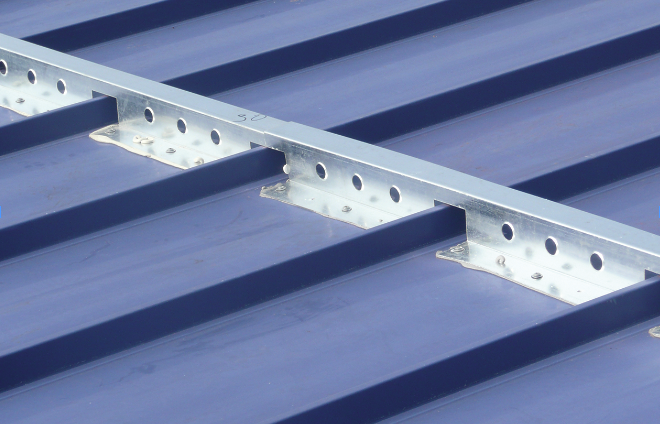

Hat Over Hat.

Using this method you would place a short +/- 6” “blocking” hat on every purlin and eave line that is taller than the existing panel ribs (2” to 3” typically). These pieces run parallel to the panel ribs and are attached to the existing purlins then another hat is placed on the top of the blocking, above the existing purlin rows, fastened as required. Spacing of each is determined by design requirements. Note this framing is not appropriate for attachment of new screw-down panels due to its rigidity, not allowing for proper expansion/contraction.

Purlin Over Purlin.

This system is similar to the hat over hat above except it uses Z-shaped members in lieu of hat members. It typically requires the use of clips to properly support the blocking Z’s attachment to the existing purlins. Additional bridging to control roll-over of the upper Z purlins may also be required.

Tall Clip.

This system is exclusively for new standing seam roof panels. It is attached to the structure by a tall clip holds the base of the new panels above the ribs of the existing building. It does not require additional framing except around openings but is sensitive to the modularity of the existing roof panels. System capacity may be limited by existing purlin spacing.

Notched Z’s.

This is a system that uses Zee-shaped members that have oversized notches punched out of the vertical part of the section that allow the existing metal panels ribs to pass through the Zee. They will work with any existing and new metal roof system. They mate easily with grid framing when needed to reduce existing purlin spacing and can be sized to add insulation. Notched Zees have also been shown to add capacity to the existing purlins, this can be important when adding photovoltaics. Note: They are sensitive to the modularity of the existing roof panels.

Thostenson explained that while builders consider these diverse installation methods, “They can tailor their approach to the specific project requirements, emphasizing both structural integrity and sustainable practices in the retrofitting process.” MR

Solving Issues and Challenges

MBCI’s metal retrofit systems solve issues and challenges with tailored solutions for each unique project. MBCI helps determine the project solutions, and also develops budgets, estimating, engineering, and a complete set of shop drawings. MBCI offers five main retrofit options: Retro-R, Double-Lok Over R Panel, NuWall, NuRoof, and Roof Hugger. “These installation methods include options for standing seam roofing, an exposed fastened overlay panel, a solution for retrofitting walls, creating a completely new sloped roof plane over an existing structure, and usage of sub-purlin systems to create a new roof plane over an existing slope,” Thostenson said. “Unique to unique to MBCI is our Retro-R panel. This is an exposed fastened overlay panel for installation over an existing R panel on either the roof or wall. It has a Dripstop membrane on the bottom side of the panel to prevent any metal-to-metal contact with the old roof or wall upon install.”

Englert’s metal retrofit roofing product distinguishes itself through several unique features, specifically its industry-leading warranty encompassing both finish and weathertightness capabilities. “In contrast to traditional offerings, our methodology incorporates collaborative input from key stakeholders integral to the design of the system. By involving the contractors in the selection of components and ensuring that their preferences are considered, we provide a tailored solution that aligns with their specific needs and preferences. Moreover, our product … is backed by comprehensive testing conducted by Englert. This testing process ensures that our metal retrofit roofing product not only meets but exceeds industry standards for performance and durability.”

Roof Hugger is unique because it has done extensive testing so that it can have a basis for designing and estimating our projects. “Notched Zee’s do not perform the same as regular symmetrical Zee purlins,” Nelson said. “It is critical to understand this difference so you can properly design your project. We have also demonstrated, again by actual ASTM testing, that our products can add strength to the purlins in most existing buildings. Does it solve the problem that this product is intended to solve in a different way than other products? Most other products do design and engineering by section properties alone. This is fine for solid and symmetrical products but when you cut notches into these parts, that all changes. The only way you can know true performance is to test actual conditions in an E-1592 test chamber with various existing and new panels.”

TopHat Framing Systems makes multiple framing systems. Its flagship product is a patented roll-formed pre-punched hat channel. When attached through the existing panels to the existing purlins, it creates what is called a composite purlin. “This composite purlin has been shown to significantly increase both positive and negative load capacities,” said Tim Lane, president, TopHat Framing Systems. “These increased capacities allow building owners and designers to move forward with the project with greater confidence in the system’s ability to meet the current codes. Since TopHat recognizes the significance of examining these load capacities, we have designed free of use the TopHat Design Tool. The TopHat Design Tool is able to show improvements in positive and negative load capacities, project specific. MR

Resources

Englert Inc.

Perth Amboy, New Jersey

(732) 826-8614

MBCI

Shelbyville, Indiana

(844) 327-1748

McElroy Metal

McFarland, Wisconsin

(608) 838-1331

Roof Hugger Inc.

Lutz, Florida

(800) 771-1711

TopHat Framing Systems

Mentor, Ohio

(330) 931-9201

RetroFit Clip

Manitoba, Canada

(800) 431-9661