www.marcoindustries.com

Determine Gauge, Spacing & Wind Load Requirements

• Clips should be approved by the metal roofing manufacturer for the panel they are to be used with. The gauge of the clip as well as the vertical spacing of the clips should also be considered, which will affect the measurements of the wind loads.

• A level roof deck is very important for the proper function of clips. Uneven decks can cause the clips to put the roofing in a bind, which can lead to panel distortion or improper snapping or seaming of the panels at the sidelap.

www.magerack.com

Consider the Elements’ Effects on Fasteners

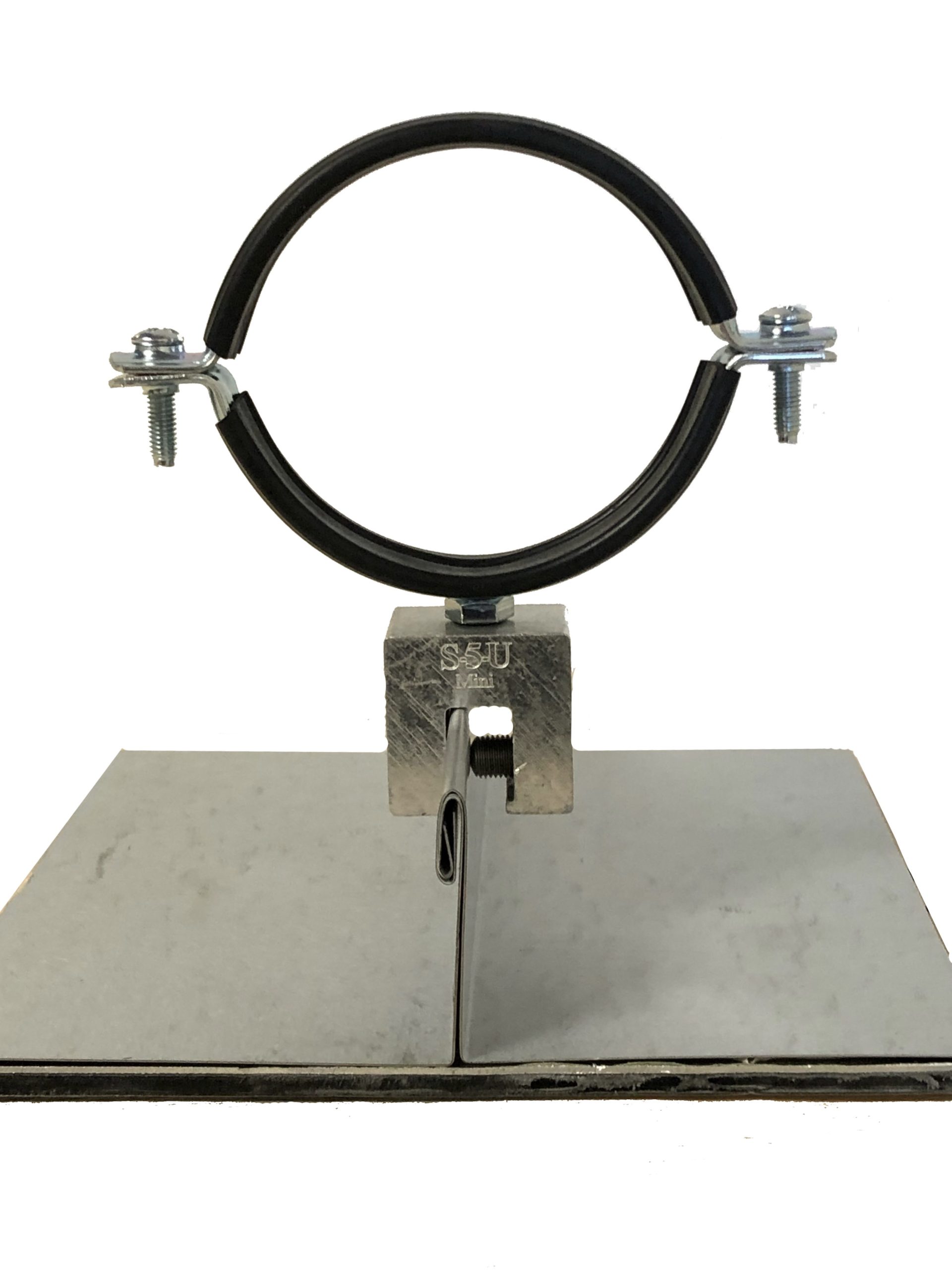

• Depending on the required holding strength, contractors can install clips, brackets, or clamps to the side of the rib or seam using setscrews or self-tapping screws, or install them into the structural element of the roof using lag screws with roof penetration. Attaching to the side of the rib or seam is easier to install and better for waterproofing. Waterproofing is very important. Water doesn’t stay on the top or side of the rib for long, but may stay on the flat or valley areas.

Keep Your Connections Strong

• Most clips, brackets, and clamps are strong themselves and stronger than the metal roof. The weak area is the connection between these products and the metal roof panels. When securing to the metal roof, make sure to use appropriate screws and do not overtighten them.

www.s-5.com

Select the Right Fastener for the Project

• Determining the appropriate clamps or brackets required for your project is math- and science-based—not guesswork. It is contingent on the specific application of the product on a given project. The load (or force) that any connection experiences in service must be matched to the allowable strength of the clamp or bracket for your metal roof’s specific gauge, profile, and manufacturer. There are no codes or standards for design, manufacture, use, or testing of attachments, so it is a “buyer-beware” scenario. Without proper testing/engineering, you are rolling the dice.

• Use products that are: proven through ISO 17025 certified testing to withstand intended design loads; engineered and designed in accordance with project specifics; produced in an ISO 9001-15 audited facility with quality standards to assure product consistency; proven to perform for the entire anticipated roof service life; and limiting your liability with a written lifetime warranty. Seek a manufacturer that offers web-based tools and calculators to assist with matching clamps or brackets to specific roof profiles and gauges.

www.trasnowandsun.com

Important considerations to keep in mind when selecting the proper clip or clamp:

• It’s a simple concept really: if you play with fire, you will be burned. So as it is with considering what clips or clamps to use. If your roof is steel, use steel clip or clamp devices. Do not put copper or aluminum on a steel roof and vice versa. By mixing the metals with snow retention devices, you risk galvanic action (corrosion).

• When considering a snow retention device, do not assume that you can place one or two rows near the roof eave. This is a common mistake and can result in snow fence failure due to using a system that was not engineered. When the snow releases on this type of amateur design, it can damage penetrations, gutters, and the snow retention devices themselves. Sometimes whole panels slide off. Various factors must be considered when safely laying out your snow retention. Also, avoid penetrating the roof system! This will void the manufacturer’s warranty on the metal roof.

A general tip regarding the proper installation of these metal roof accessory products:

• Words cannot express the importance of an engineered layout! Do not be afraid of the word “engineering.” Some reputable roof attachment companies provide this service for free. All it takes is gathering a few facts.