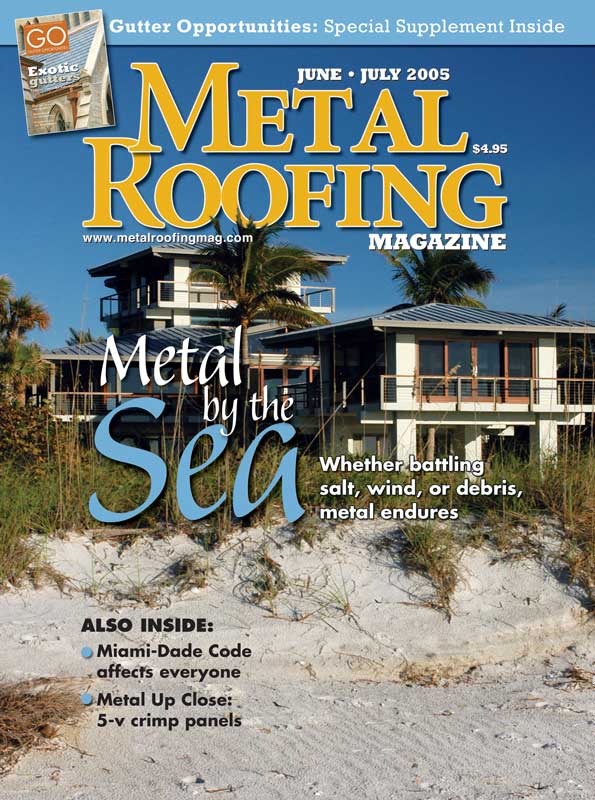

It may be the most versatile through-fastened metal roofing panel. It’s on everything from tobacco barns and chicken coops to condominiums and million dollar homes. Yes, 5-v crimp panels can do it all, and have been for possibly more than 100 years.

Jim Horton, vice president of research and development at Southeastern Metals (SEMCO) says 5-v is an old classic. “The first two metal roofing profiles that were patented were 5-v and what most people call ridge roll,” he says. “Obviously, it’s called 5-v because of the five v-shaped ribs, which were added for rigidity. The biggest innovation for 5-v was the anti-siphon groove (between the two outer v-shaped ribs). Whenever you have sidelaps, you get the capillary action that allows water between the panels. With the anti-siphon groove, that water drains off the roof without getting under a panel.

“When we install 5-v, we put the fasteners in the top of the (overlapping panel’s) inside rib to keep the penetration away from the water.”

Horton says one of the biggest mistakes made when installing 5-v crimp is putting the fastener in the outside rib. The groove between the double Vs on each side of the panel is to siphon water captured by capillary action off the roof. Putting a fastener in the outer panel places the penetration between the siphon groove and the outer edge of the panel — where water can get at it.

“With the 5-v panels, with the wind upload requirements, you have to run fasteners 16 inches on center all the way up the panel in high wind areas,” says Horton. “Inland, you can run fasteners 3 or 4 feet on center, so they’re not so noticeable.”

Several manufacturers have altered the original profile to create a larger anti-siphoning channel. McElroy Metal and Wheeling Corrugating panels feature a smaller outer v-rib on the sidelap that ends up under the adjacent panel. When installing 5-v panels with nails, both McElroy and Wheeling recommend going through the ribs; screws with neoprene washers should go through the pans, near the ribs.

Metal roofing manufacturers and installers contend that bare galvanized or Galvalume is the most popular look among homeowners who choose 5-v crimp roofing. It’s a look popular along the coast, especially in Florida. DAN’S CUSTOM SHEET METAL PHOTO

This residence in New Smyrna Beach, Fla., was recently re-roofed in 5-v Galvalume. It is a 750-square foot wood-frame Cracker shotgun, with two bedrooms and one bath, built in 1918. The roof, installed as part of a complete renovation, is sloped at 4:12 with 5-v installed over 1×4 sleepers over 2-inch rigid insulation over the existing 1×4 heartpine decking. archDESIGN PHOTOS

Union Corrugating features a “U” over “V” anti-siphoning channel system to provide leak resistance. The outer ribs of the overlapping panel form a shallow u, leaving a v-channel between the ribs of the bottom panel. Union also recommends using 3/8-inch butyl caulk tape on all sidelaps, especially for shallow roofs. The important thing to remember is to not block the siphon channel with the tape.

Thom Wheeler, intern architect and president of archDesign in New Smyrna Beach, Fla., works with a 5-v system from Englert. He says there is a segment of homeowners and architects that require concealed fasteners, although he prefers the 5-v roofing panels. “I like the look of it,” he says. “It’s basically the most economic metal roof.”

Economics plays a big part in the love affair with 5-v, according to Danny Osborne of Dan’s Custom Sheet Metal in Naples, Fla. “It’s an exposed fastener, so it’s less expensive,” he says. “You get all the benefits of metal and the same look as standing seam.”

Osborne says labor costs are considerably less because it installs faster than standing seam. Osborne manufactures his 5-v with machines from Roll Former.

Horton believes 5-v reached its peak in popularity a few years ago, and now some of the snap-lock panels are edging it out because they have concealed fasteners.

Who loves 5-v?

Most 5-v panels and 5-v roll formers are sold in Florida. It is most popular on the Cracker style houses with large porches.

“In a nutshell, the 5-v crimp roof was found on the old farmhouse and chicken coop,” says John Dumke of Roll Former. “Today, it’s still used on the old farmhouse and chicken coop, but it’s also on the $300,000 and $400,000 condominiums as well as million-dollar homes. And it’s the externally fastened, screw-down overlap panel, and they’re putting it on whatever. They call it the old Florida look.”

The Cracker house was originally a wooden shelter built by the early Florida and Georgia settlers. The most noticeable feature of a Cracker style house is its wide porches, sometimes wrapping around three sides of the home. Those porches provided shade for windows and walls, and were almost necessary for survival before air conditioning. The name Cracker is said to come from the early settlers who were ranchers and used the “crack” of the whip to round up their cattle. Native Floridians came to be called Crackers.

Through the years, Roll Former’s 5-v machines have been good sellers, but lately have become even more popular. “Ninety-nine percent of them are going into Florida, and unfortunately, it’s because four hurricanes visited Florida last fall,” Dumke says. The Roll Former machines can run coil anywhere from 14 to 28 inches wide. The most popular is 27-1/2-inch coil that makes a 26-inch panel. With a 1-inch overlap on both sides, you get 24 inches of coverage.

“It’s popular in the south, particularly in the southeast; and, to some extent in the northeast,” says Bill Croucher of Fabral. “It’s because of the old residential look. It’s not used much in architecturally specified jobs. It’s got a very clean look, a wide flat pan and just a couple of inverted Vs. It’s not real busy. It works well over a solid deck most commonly used in residential applications.”

Croucher says 5-v roofing is most popular in unpainted, galvanized or Galvalume. “They just prefer that look,” he says. “We offer it in a variety of colors, but it’s most popular in unpainted.”

The bare metal provides the more traditional look homeowners are after. Hot-dipped galvanized steel roofing provides the sacrificial protection of zinc, a beneficial quality in coastal areas where metal is subjected to corrosive saltwater air. Galvalume, an aluminum-zinc alloy-coated carbon steel, combines the barrier corrosion of aluminum and the sacrificial protection of zinc.

“We have one branch in Wilmington (N.C.) where people are just in love with the 24-gauge Acrylume,” says Keith Coombs of Coastal Metal Service in Goldsboro, N.C. “They’re selling a whole pile of that stuff. People see it on one house and they want it on theirs. The painted 5-v is popular, too, but in Wilmington, it’s the Acrylume.”

Osborne concurs: Bare Galvalume is the most popular for his customers. The four most popular colors are white, Sierra tan, forest green, and light blue.

The old and new

In a pre-World War II catalog from Wheeling Corrugating, one of the roofing panels offered is a v-crimped beaded panel. The 24-inch panel, available in 24-gauge and lighter, features one “v” on each sidelap with two beads to a sheet, 8 inches apart. “The beads stiffen the sheets and present a nice appearance,” according to the catalog. The panel is designed so one “v” overlaps the “v” on the adjacent panel.

Coombs says 5-v panels in North Carolina date back to the 1800s, when it was used on tobacco barns, so most of the attraction has to do with tradition — 75 percent of the 5-v panels Coastal Metal manufactures are for residential applications. “Even on some of the more expensive houses, that’s what they want on it now,” Coombs says.

To someone who has never lived along the southeast coast, the unpainted look may give the impression of an inexpensive tin roof, more suited for tobacco barns, chicken coops, or whatever out building they can name. Some of those people are coming around.

“It’s a very, very old product, and we never thought we’d have 5-v in our line, until we saw how popular it was in southeast coastal areas, and it’s almost all residential,” says Ken Gieseke of McElroy Metal. “It’s just a look people like.”

He says the revelation hit McElroy about eight years ago. Green may be the most popular color for 5-v panels, but like most manufacturers, the highest demand for McElroy is for unpainted, acrylic-coated Galvalume. “It’s a through-fastened panel, easy to install, 24 inches wide, so it comes together real quick. It has an aesthetic appeal that’s very popular in coastal areas,” he says.

Another manufacturer to jump on the 5-v bandwagon is Englert. “Our approach was always that we weren’t interested in the ag or utility panel market,” says Kevin Corcoran, Englert’s vice president of corporate development.

But Corcoran toured the four hurricane zones in Florida and Alabama last fall and was surprised to see 5-v crimp panels on multi-million dollar homes. “Those people can afford to put any kind of roof on their house they want to and they were installing 5-v crimp,” he says. “So we took another look at that market.”

Englert put together a 5-v crimp program for a good customer in Florida with machines from Roll Former. “What we did differently was offered a premium product,” Corcoran says. “We use architectural details on the eaves, rakes, valleys, the whole thing. It’s a 24-gauge Galvalume or Kynar-painted Galvalume, no SMPs or modified SMPs, strictly Kynar.”

The customer was using a 24-inch coil to produce a 21-inch pan from eave to ridge. Englert handles machines and coil for 5-v crimp in 26- and 24-gauge steel, as well as .032 aluminum.

What is the Florida fascination with 5-v crimp? Corcoran is first to admit it’s not based on performance. “When you’re dealing with exposed fasteners, over the course of time you’re going to have holes elongating,” he says. “It’s just the look, that Florida Cracker or Key West look. You drive south of Tampa, along the coast, you see it on most of the outrageously expensive houses. There are certain parts of Florida they like it as a bare metal. It’s driven by history and driven by architects.”

History, tradition, architects, or just keeping the chickens dry — 5-v roofing can get the job done. MR