Underlayment must be used when installing a metal roofing system over a roof deck. We asked underlayment suppliers and manufacturers for their insights and best practices regarding synthetic and asphalt-saturated felt. Specifically, we asked about the advantages and disadvantages of using synthetic and felt underlayments under metal. They were also generous enough to share installation tips to help make installation “fail-proof.”

Synthetic Underlayment Advantages

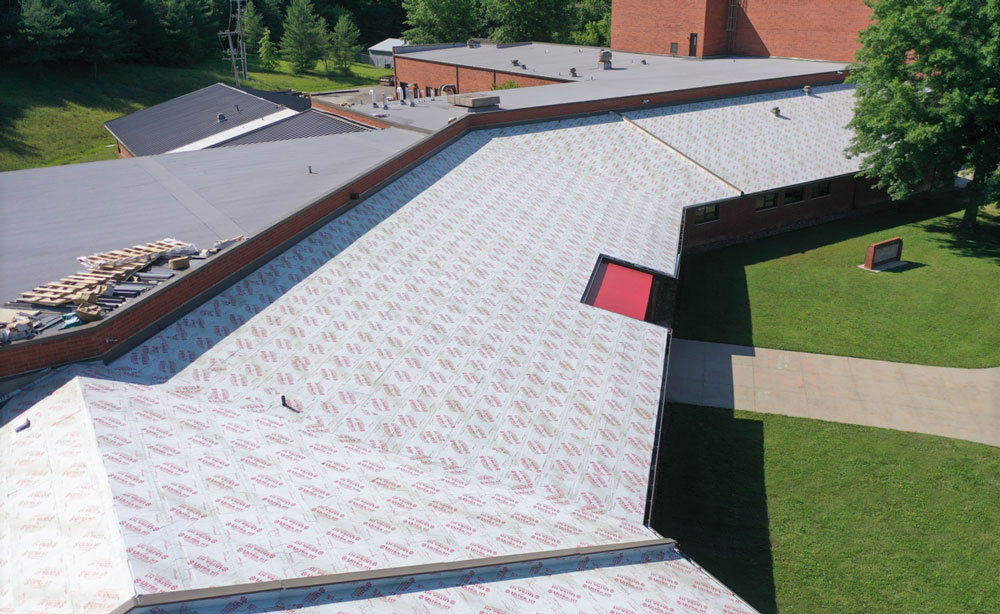

• Compared to felt, synthetic roofing underlayment is tougher, faster to install, and repels water.

• No rosin slip-sheet is necessary with synthetic underlayments. Synthetic roof underlayments that are manufactured at higher temperatures than traditional asphalt base roofing felt/underlayments do not stick to metal roofing systems at elevated temperatures.

• Synthetic lays flat for smoother, faster installation

• It provides better long-term UV protection prior to the installation of the metal roof system.

• Has better resistance to wind uplift when exposed, prior to the final roof installation.

• Can be safer to walk on, even when wet.

Synthetic Underlayment Disadvantages

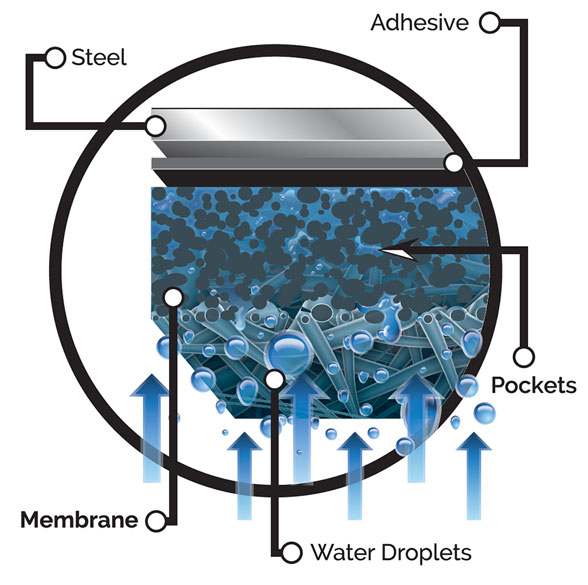

• Generally, synthetic underlayments don’t protect the roofing substrate from water penetration before, during, and after the final roofing system is installed. Should the metal roof develop a leak or damage, the synthetic underlayment does not provide a watertight seal against wind-driven rain. Only a properly installed self-adhered roofing underlayment provides complete waterproofing protection.

• Costs more than felt.

• Usually has a lower permeability rating, which is great for keeping out moisture, but slightly reduces the ventilation in the roof.

Felt Underlayment Advantages

• Costs less.

• Is available almost anywhere because it is more commonly used.

Felt Underlayment Disadvantages

• Limited exposure before it degrades; generally can’t be left exposed for more than a few hours.

• Material may dry out or leach oils in the heat, which would impact the felt’s ability to protect against moisture.

• Not resistant to high temperatures.

• Doesn’t last as long as synthetic.

• Prone to tearing in high winds and during installation.

• If exposed to moisture, the mat can absorb water and wrinkle the felt, which can prevent the metal roof system from laying flat. This is especially true with standing seam metal panels.

• Weighs more, making it harder to work with.

• The slippery surface can sometimes make it more difficult to install compared to synthetic underlayment.

• Asphalt is made from petroleum, which is a highly flammable substance and introduces concerns with regard to fire safety

• Slip sheet is necessary with asphalt-based felts/underlayments to prevent adhering/sticking to the back side of metal roof systems.

Underlayment Installation Tips

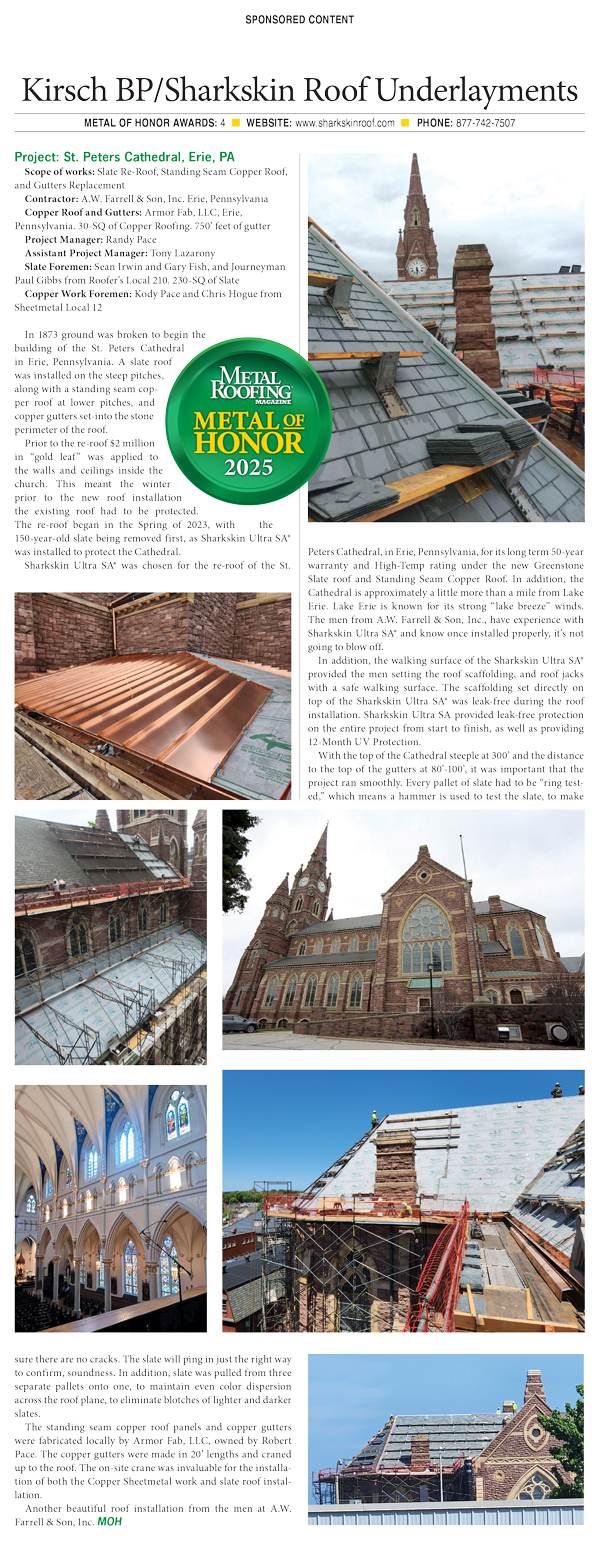

☑ “Choose a quality premium synthetic roof underlayment that is engineered for the application, roof pitch, weather conditions and primary roof covering.” — Mark Strait, Kirsch Building Products, maker of SharkSkin

☑ “Make sure you read and understand your local building code requirements. And make sure you read the underlayment manufacturer’s installation instructions. Most problems we hear about are the contractor installing the products improperly or — even worse — not following code and having to remove the material and rectifying the situation at their own expense.” — David Delcoma, MFM Building Products

☑ “It’s important to know that synthetic roofing underlayment materials are not standardized, so different manufacturers may make their products differently, and therefore have different levels of performance. Thus, it’s important to do your research and select a trusted brand.” — Maggie McQuarrie, Owens Corning

☑ “It is also important to consider the proper self-adhered product to support properties such as fire resistance. Roof coverings are classified by their ability to resist fire from the exterior of the building; an especially important consideration in areas near the Wildland Urban Interface (WUI) or in energy-generating roofing assemblies. It is important to select a self-adhered material that is tested to achieve a Class A fire resistance.” — Maggie McQuarrie, Owens Corning

Choose Wisely

What could happen if you improperly install (or install the wrong type) of underlayment under metal?

Mark Strait cautions, “Low-temp asphalt self-adhered roof underlayment can melt, oozing out from under the metal roof, and/or down through the roof sheathing, creating a big mess.

“Improper installation can lead to leakage and water intrusion prior to the final roof installation,” he continues. It can also void the metal roofing manufacturer’s warranty and cause injury to the installers, or others working over the roof underlayment.

David Delcoma, MFM Building Products, adds, “Any type of roofing underlayment MUST be rated for high temperature applications due to the high heat generated. This is significantly more important if the roof covering is copper or nickel, where extreme high heat buildup occurs. Non-high-temp rated underlayments can become brittle, crack, or in the case of self-adhered membranes, the mastic may ooze out. All these conditions can lead to water infiltrating the building structure.” MR

Metal Roofing expresses appreciation to the following underlayment specialists for sharing their expertise:

• Mark Strait, Kirsch/SharkSkin www.sharkskinroof.com

• David Delcoma, MFM Building Products www.mfmbp.com

• Maggie McGarry, Owens Corning www.owenscorning.com

• Todd Gluski, OX Engineered Products www.oxengineeredproducts.com

• Christian Rios, Levi’s Building Components www.levisbuildingcomponents.com