By MR Staff

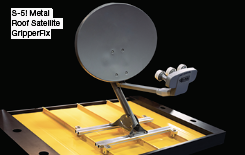

It should go without saying that the purpose of a roof is to protect the interior of the building from the elements, so you should avoid putting a hole in the roof. At the same time, you know that sometimes it’s necessary to put a hole in the roof.

Roof penetrations such as vent stacks and chimneys create a weak spot in the roof barrier that keeps water from infiltrating the building. Roof penetrations must be properly flashed to prevent water entry and the significant damage and destruction it causes.

In this back-to-basics product feature, we’ll cover some of the details to keep in mind during the selection and installation of pipe flashings.

Avoid Dual Fixity

Metal panels move through thermal cycling. The longer the panel, the more movement there is. When installing a pipe flashing, avoid fastening into the deck to allow for the inevitable panel movement. If you fasten to the plywood deck, thermal movement of the metal roof panel will cause oil-canning in the roof panel — or worse.

To prevent pinning the panel to the deck, overcut the hole in the deck so you can drive the fastener through the flange and roof panel without pinning to the deck. Use the base of your pipe boot as a template to gauge how big to cut the hole.

Avoid Intersecting a Seam

Before you install the panels, make sure roof penetrations will not intersect a seam. If the pipe will intersect a seam, move the vent pipe over a few inches and center it in the flat of the roof panel. Otherwise, a roof leak will be the result.

Carefully measure and mark the location of the pipe on the panel; cut a hole that allows at least 1” of clearance all the way around the pipe to allow the metal panel to expand and contract without damaging the pipe. Depending on the region, if panels are longer than 30’, you may want to elongate the hole.

Select the Right Size

Installing a pipe boot that is just barely big enough will eliminate the extra flexibility needed to accommodate the roof slope and movement of the roof panels that results from thermal cycling. Only use maximum pipe diameters on minimal roof angles. Aztec Washer, a leader in the flashing industry, recommends using its Universal Master Flash® one size larger on steep roofs or if the roof panels have deep corrugations. To help take some of the guess-work out of selecting a pipe boot, the company developed its “Master Flash Roof Pitch calculator” [https://rpc.aztecwasher.com/].

Cut the boot 20% smaller than the pipe diameter for a tight fit. If you cut it too big, you won’t get a good seal; throw it away and start over with a new boot.

Use a stainless steel drawband over the flashing to seal around the pipe — especially if there is a risk of severe weather or heavy snow load. Use a sealant that is recommended by the metal roof manufacturer under the base of the pipe boot.

Fastening

To assure the flange has proper contact with the panel surface, install fasteners with EPDM washers. Start by installing a fastener on each side, then work your way to the sides from the starting points. Fasteners should be no more than 1 1/2” apart. Center the fasteners in the aluminum base flange, and do not over-tighten.

Will It Last?

For hot pipes, such as wood-stove and furnace flues, use silicone pipe boots. EPDM won’t hold up to constant hot temperatures and will break down prematurely. Silicone pipe boots can withstand continuous high temperatures. Aztec Washer Co.’s EPDM Master Flash® products are tested to withstand +275ºF (+135ºC) with intermittent heat exposure and +212ºF (+100º C) with continuous heat exposure. Their silicone Master Flash® products are tested to withstand +500ºF (+260ºC) with intermittent heat exposure and +437ºF (+225º C) with continuous heat exposure.

Details positioned on a rooftop are blasted by UV light; black EPDM flashings or state-of-the-art silicone flashings are made to withstand the beating. Aztec Washer’s Master Flash® products are made of EPDM or high-temperature silicone. These roof pipe flashings are compounded specifically for maximum resistance to weathering due to ozone and ultraviolet light.

Conclusion

This is, by no stretch of the imagination, all you need to know about pipe flashing installation. As always, if you have questions about a flashing product or its installation, contact your supplier or the manufacturer. MR