By Josh Krohn, Triangle Fastener Corporation

Modern metal roofs provide long term durability and protection from nearly anything mother nature can throw at them. They also come in a variety of materials, textures and attractive colors. The combined aesthetics and enduring functionality can easily meet a project’s architectural and the structural performance requirements. Installing a metal roof is a great choice, so how does it get attached?

When talking about fastening roof panels to a structure we can divide the connection into two main types: exposed fastener systems and concealed fastener systems. As the name implies, exposed fasteners go through the roof panel and into the structure leaving the head of the fastener exposed on top of the roof panel. Concealed fasteners are typically used with a clip or installed through a slot in the panel to hold down the edge of a roof panel. Then they are concealed as the next panel is installed over the clip and fastener.

The advantages of an exposed fastener roof system are that it is less expensive, easier to install and materials are more widely available when compared to a concealed fastener roof. The challenges of the exposed fastener system are the number of roof penetrations, the risk of improper fastener installation and potential fastener back-out. Thermal expansion and contraction of the panel can be a challenge as well. Contraction can put stress on the penetration points, potentially elongating a hole in the panel. Expansion can lead to oil-canning. This movement can cause a pathway for water to get through the roof.

The advantages of a concealed fastener roof system are that there are no roof penetrations created by fasteners, the clips or pre-punched slots used for attaching the panel are designed to let the panel move without putting stress on the fasteners and reducing the risk of oil canning. The disadvantages of the concealed fastener roof are the higher cost and the lower number of qualified installers available.

Both concealed and exposed fastener panels can be installed on a number of different substrates like plywood, OSB, lumber, cold-formed steel, steel deck, hot rolled steel beams, concrete and masonry. A critical component of the design of the panel assembly is specifying the correct fasteners that hold the panel or panel clip to these substrates. There are fasteners with a variety of head styles, point styles, diameters, lengths, materials and finishes to choose from. The appropriate fastener and spacing of those fasteners for use with each panel type and substrate can normally be found in the panel manufacturer’s installation guide, which can be found on the manufacturer’s website. If a unique situation or a tough application comes up, you may want to contact the fastener supplier to see what other options are available.

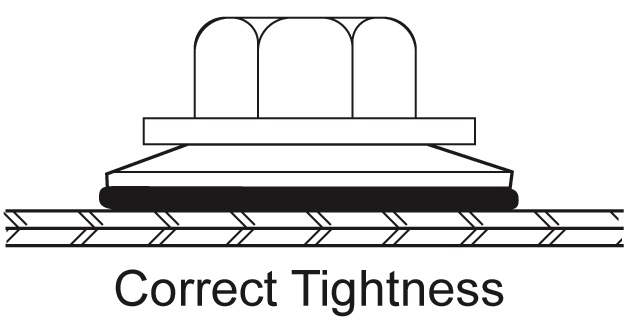

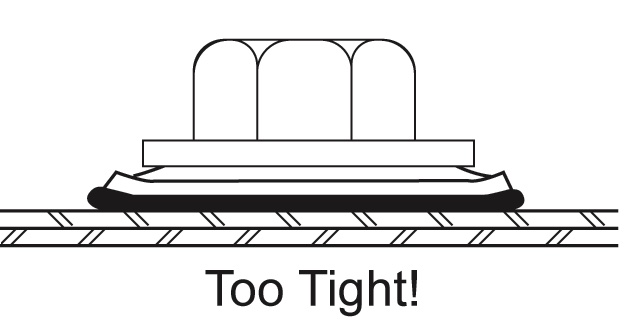

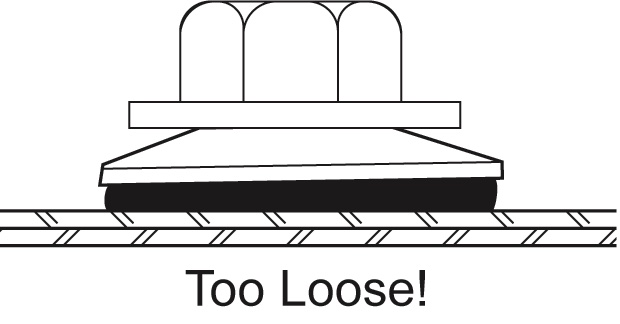

Proper installation of fasteners is important, too — especially in through-fastened panels. Since exposed fasteners pierce the roof panel, a sealing washer is needed to keep water from following the path the screw created to the substrate. To assure a proper seal, screws should be tightened until the EPDM sealant protrudes just to the outer edge of the backing material. This also is a great way to visually inspect the screw to assure it is not over-driven. If the screw is under driven the sealant will not be compressed. If the screw is over-driven the sealant will push out well beyond the metal backing and sometimes tear. A screw gun with torque control, like a clutch, or depth sensing nose piece should always be used to prevent over-torqued and unseated screws.

Concealed fasteners do not need to seal out water, so over-driving is less of a concern but the same care should be used while installing them. Impact guns should not be used. Using impact tools to install screws can cause the head to separate from the body due to the high torque and impulse generated by the tool. Screws can also be easily overtightened, which can lead to connection failure when an impact gun is used.

To avoid the risk of the head separating from the body of the screw, impact guns should not be used. Screws should be installed perpendicular to the substrate. Images courtesy of Triangle Fastener Corp.

Care should be taken to ensure fasteners are installed perpendicular to the work surface. Installers should let the drill point of the screw and the screw gun do the work. Excessive pressure or stabbing the fastener into the surface are not needed and could damage the screw.

After installation is complete it’s a good idea to perform routine inspections seasonally and after significant weather events. Well designed and properly installed metal roofs look great and perform well for decades and an inspection plan will help mitigate any potential issues and ensure the roof will last many more years. MR

Josh Krohn is the Engineering Services Manager at Triangle Fastener Corporation.