By Sharon Thatcher

A growing number of metal roofers have added job site or stationary panel roll formers to their equipment inventory. Seasonal slow-downs—occurring in winter for most of the country—are a great time to inspect your equipment and make any repairs or upgrades in preparation for the upcoming prime roofing season.

Frank Schiene, Vice President of Support for Metal Rollforming Systems (MRS), spends his days fielding phone calls to help owners keep equipment running smoothly and trouble-free. He advocates for a routine schedule for maintenance on a daily, weekly, monthly, and annual basis. He offered his insights in a presentation, “Maintaining Roll Formers and Optimizing Performance,” at the 2019 Construction Rollforming Show in December. We later caught up with him for additional tips.

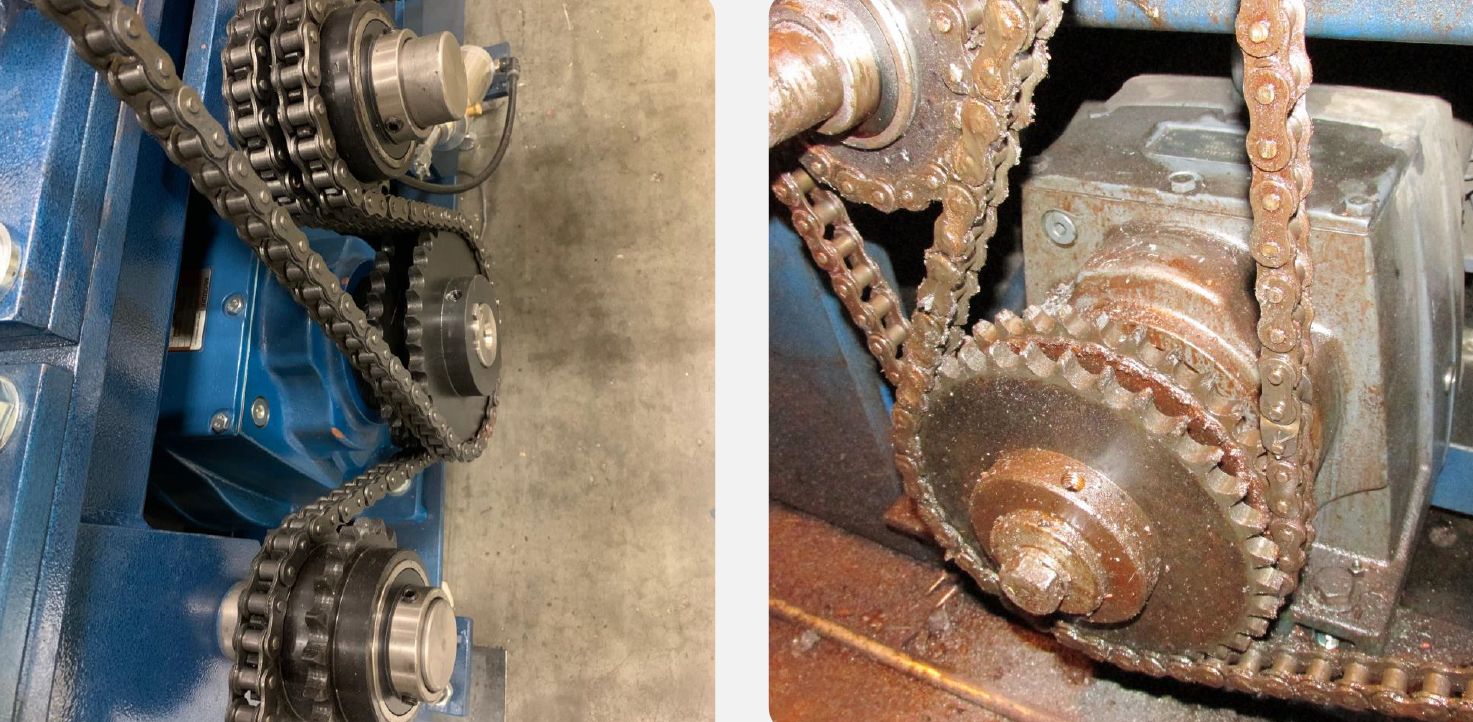

One of the common oversights is not checking chain tension, he noted. “The more slack you get in the chain, the more it jerks the roll former,” he said.

He likened it to pulling a car out of the snow: With the rope taut, you can accelerate and pull the car out. Keep the rope loose, and when you accelerate you are likely to pull the bumper off the car.

“Allowing chains to remain loose ends up ruining shafts, keyways, and sprockets, and stretching chains. …It snowballs literally into major overhauls,” he explained.

Improperly adjusting shear blades is another common error, leaving burs on the metal and creating rough edges that run the risk of cutting handlers.

The last error points to what really bothers Schiene the most in the industry. Beyond his concerns for keeping roll formers in peak condition for productivity, he is a huge advocate for keeping operators in peak condition through strict protocols for safety during the maintenance process. He spent more than a dozen years out in the field as a technician and has seen his share of missing fingers and torn flesh caused by often preventable accidents.

“One of the biggest things I find is that when people get done doing maintenance, they’re not replacing guards; they’re taping down limit switches to look at a problem, then not removing the tape; or they bypass the safety circuit to adjust the shear and don’t realize the machine is still live and they can get shocked. Any time you bypass safety equipment guards, safety switches, or emergency stops, you’re posing a safety hazard.

“I was a technician,” Schiene continued. “I’ve built, overhauled, set up, done troubleshooting, that’s why I am so passionate about safety because I’ve seen things that shouldn’t happen.”

Things he has witnessed: “People cleaning tooling while the machine is running. They think they’re doing good by trying to clean the tooling to get a good panel. They’ll clean it with their hand and then their hand gets sucked into the roll former, losing fingers, or worse.”

Be extra cautious when wearing gloves and loose clothing while doing machine maintenance. “Handling metal with gloves is OK, but people get carried away and try to do things within the roll former, especially on the chain side. That’s where I get nervous,” he said.

The same applies to loose-fitting clothes like jackets and untucked shirts.

Bottom line, Schiene advocates for taking time for safety—carefully assessing the situation before making repairs or conducting routine maintenance.

“The biggest thing is people trying to do it in a hurry,” he said. “If you don’t use the proper procedures, that gets people hurt. I’ve done just about everything on a roll former you can do and I still have all my fingers. …I’m a lot more passionate about safety than maintenance.” MR