The challenges we’ve seen over the last two years persist. It seems we can’t see a day pass without hearing about supply chain disruptions, price increases, and labor shortages. We reached out to metal roofing suppliers, including the manufacturers of the Top 10 Products of 2021, for their reflections on the year 2021 — and their opinions of what may come to be in 2022.

ATAS International • www.atas.com

Lee Ann Slattery shares ATAS International’s view on the challenges and opportunities of the past and coming year. When it comes to the biggest challenges that construction-related businesses will face in 2022, Slattery says, “I think that material availability is still going to be a challenge, which then, of course, affects the cost of materials; but I do not think it will be as bad as it was in 2021. The challenge will be mitigated with more materials being manufactured in the US, which will decrease the lead times of materials and avoid the costs of ocean freight and tariffs. With more material production within our country, that should also have a positive impact on lower costs.

“I think the biggest challenge in both construction and manufacturing is the labor shortage,” she continues. “Even though the unemployment rate is decreasing, there are still many people retiring or otherwise choosing to leave construction and manufacturing. Our country needs to focus on training programs for these jobs, starting at the middle and high school levels. The stigma against trade schools, versus college, needs to be overcome. Most positions within construction and manufacturing are good paying jobs, and students can begin their career with little to no student loan debt. Many people within the trades quickly move into higher level positions, and some start their own businesses. We are also starting to see more women working in these industries, which will set the stage for even more women entering those positions.”

It’s important to get involved whenever and wherever you can. “Regarding the labor shortage in our industry, I would encourage people to support our youth in exploring career options within construction and manufacturing,” she says. “This can be done through getting involved in the local trade and vo-tech schools, offering internships, and participating in career fairs. Many STEM (Science, Technology, Engineering, and Mathematics) camps occur all over the country, and some seek volunteers; the ideal volunteer is working in those areas, to share their experience with the students. I’ve been involved with our local ‘Let’s Build Construction Camp for Girls’ since its inception in 2017. This annual camp is free to middle and high school aged girls who want to learn about construction and manufacturing. It’s great to see these young women grow in a short period of time, not only in their skills, but also in their self-confidence. There is nothing better than the excitement on a girl’s face after she wires a light and then flips the switch to see the light come on!”

Slattery points out the manufacturing sector continues to be strong, and a key to overcoming supply chain issues is bringing more manufacturing back to the US. “The manufacturing sector of nonresidential construction in 2021 was the largest by far, compared to other sectors. More production facilities are being built in the United States to combat the supply chain issue of obtaining materials manufactured overseas.”

When it comes to strategy for 2022, don’t take your relationships for granted. “Building and maintaining strong relationships with your suppliers can help in these difficult times,” Slattery advises. “Even though there will still be issues with costs and availability, those long-term suppliers will remember your loyalty, and will try to help expedite things whenever possible. If a contractor has always shopped around for the lowest possible material price for many years, without concern for the service, reputation, quality, and reliability of a supplier and the value those attributes bring, it will be more difficult to obtain materials as availability challenges occur.”

McElroy Metal • www.mcelroymetal.com

Labor challenges are a common theme from builders around the country. Labor has been a challenge for several years now, and unfortunately builders will probably be challenged again in 2022. Fortunately, it appears that colleges and associations, such as the NFBA, are encouraging the construction trades as career choices and developing curriculums and tools to help train and educate.

Ken Gieseke, Vice President of Marketing at McElroy Metal, states they continue to see growth in the residential metal roofing segment. “Homeowners are becoming more educated about the benefits of metal roofing and have grown tired of regular replacement of conventional shingles. Metal roofing market share has grown the past several years, so more and more homeowners are being exposed to metal roofing, getting educated about metal roofing, and then installing metal roofing on their own homes.”

This positive state of affairs gives Gieseke hope for the coming year. “We remain optimistic and believe the construction market will have another solid year in 2022,” he says.

MFM Building Products • www.mfmbp.com

Price increases for raw materials have definitely affected customers, according to David Delcoma, Product Marketing Manager at MFM Building Products. The company is not known for issuing price increases throughout the year, but 2020 and 2021 were a different story. “Every raw material we purchased has been subject to multiple price increases. Everything from the key ingredients in our mastic down to the packaging supplies have seen increases,” Delcoma explains.

MFM is betting on the construction industry going strong in the coming year. Delcoma says, “MFM foresees another strong year in the construction industry, both residential and commercial. The slowdown may occur in 2023.” Of course, unforseen outside forces can affect the industry. Delcoma put it this way: “For most manufacturers of building materials, natural disasters like hail, tornadoes, flooding, and hurricanes can drive product demand. Of course, these cannot be anticipated, but can have a major impact on the construction industry.”

Throughout 2021 and 2022, product availability for builders and the corresponding increase of those items were a major hindrance to the construction industry. Delcoma continued, “At MFM, we understand the value of being able to deliver the product at a competitive price. We anticipate that builders will still be subject to longer lead times in 2022. However, MFM has placed a major focus on having inventory in stock for 2022. Builders need to anticipate these delays and work closely with their distributors to ensure that product is available when needed.”

Delcoma has further advice for builders: “Focus on product quality, availability, and cost. We’ve seen many projects waiting for months on one or two products that were delayed. A local house sat for over 12 weeks waiting on the windows and doors to arrive. Nothing else could move forward until these items arrived. A builder needs to be conscious of these unknown factors.”

Changing prices may cause difficulties for builders in the next year. “Some raw material pricing has leveled off during 2021 Q4,” Delcoma says, “whereas others seem to be just beginning. What is unfortunate is that many raw material suppliers will pass on an increase with very little warning, which hurts the manufacturer, distributor, contractor, and ultimately, the consumer. Our suggestion is to assume that pricing will continue to increase and operate under that premise. Some customers have increased their orders to ensure product availability.”

Overall, MFM appears poised for good things to happen in the industry. “MFM underwent a 2021 Expansion Project to significantly increase our manufacturing capabilities for 2022. This in-excess of $10 million dollar project includes a new warehouse facility, production equipment, support equipment, a new fulfillment center, and state-of-the-art Research and Development Laboratory.”

Besides facility expansion, MFM has other big plans in store. “MFM plans on introducing several new products in 2022 through our new Research & Development Laboratory. We are not at liberty to say what these products will be at this point,” Delcoma says, “but suffice to say that it will give our customers a wider selection of product offerings. MFM is unique in that we supply a complete envelope of waterproofing products from the rooftop to the foundation. These new product introductions will complement our existing product offerings.”

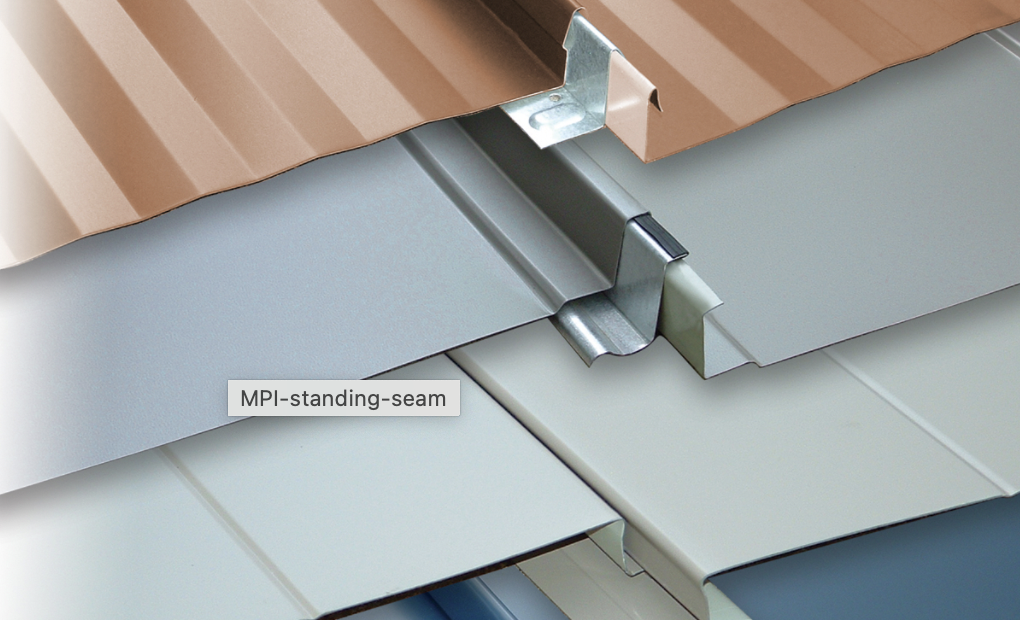

Petersen Aluminum • www.pac-clad.com

Mike Weis, vice president of sales and marketing at Petersen Aluminum, says, “Builders will face many of the same challenges in 2022 as they did in 2021. The flipping of the calendar to a new year will unfortunately not wipe away the conditions that have existed over the past two years. Supply disruptions will continue, inflationary pressures will impact everyone, labor shortages will persist, bottlenecks in shipping will remain, and demand for more metal will come from all segments of the world markets. Builders can mitigate these by being open and communicating realistic expectations with full transparency to their customer base. Many have also learned that contractual steps can and should be taken to better protect them from the risks that are out of their control.”

S-5! • www.S-5.com

2021 A Year of Turning Problems into Opportunity

Instead of looking for problems in the midst of the pandemic, we looked for opportunity. That opportunity was (and still is) out there—to respond to the near term, manage differently and plan for the longer term. Just shift thinking, re-direct resources, re-invest and prepare for the (new and increased) demand.

Within the health crisis, we got creative with our sales process and came up with new ways to stay in front of customers, educate and train them. We used the time to survey our customers and gather some insightful feedback. We expanded our marketing efforts, improved our processes and invented new things.

At the onset of this pandemic, we learned what to do and not to do; we gained knowledge and understanding of how to plan better for the future. Most importantly, we prepared for the pent-up demand we had predicted. It isn’t rocket science but only requires some common sense. We were ready to respond.

Construction Up or Down in 2022?

The increase or decrease in the rate of construction has much to do with the fiscal policies of the Fed, the government in general and what happens with the Build Back Better Act by the time it works its way through the U.S. Senate. These are all external forces beyond our control.

Our economy is in a very volatile state because the Fed and administration are being irresponsible with the supply of money. The Fed sets interest rates to control inflation. But not now. Inflation is rampant and the Fed keeps suppressing interest rates. A lot depends on public policy regarding money supply.

The other issue is the dollar losing value (you only need to go to the supermarket for proof), but other currencies are losing value as fast or faster. It doesn’t seem to be slowing things down as consumer credit is expanding (and spending along with it). There was such a pent-up demand from 2020 when it was hard to get anything built, so businesses and families are doing what they have to do—buying what they need regardless of cost.

Supply Availability and Costs Going Forward

At S-5!, we have seen cost escalation and constrained availability like we have never seen in five decades—mostly to the fallout from the pandemic. Companies had shut down production and inventories became decimated. Extreme weather events in 2021 also did not help. The response from buyers was some degree of over-reaction. Spontaneous reactions propelled by fear and fueled by federal debt burdens and cheap credit alter rational logic.

Throughout the course of the pandemic, steel production companies had major shutdowns. That’s raw material at its source. Other mills beyond steel, like aluminum, stainless, lumber and consumer goods had shutdowns as well (both domestic and foreign). The result is an increase in demand along with a decrease in supply. Because of this, “too much money was chasing too few goods” (Warren Buffet’s definition of inflation). Costs should begin to decrease by Q2, 3 and 4 2022 as raw material producers get geared up and freight channels loosen.

With the deceleration of construction on the heels of projects previously on hold and now being completed, several factors will work together to levelize costs and bring them down a bit. As far as supply availability, from a company perspective, we haven’t waited to find alternative sources. We have those sources on board now and are still able to maintain our long-standing relationships with key suppliers and customers. They understand our situation. They are in the same boat—trying to meet the demand. One of our key suppliers for raw material (we are one of their largest customers) recently said to us, “…help us out and find a secondary supplier because we just can’t meet your demand.”

The Labor Shortage

The labor shortage should improve in mid-2022 since the generous benefits provided by the federal government have ended. S-5! has experienced the labor shortage firsthand at our manufacturing plant with competition from government-subsidized income paying so many to stay at home. As a result, companies like ours have had to shift and invest more in their people—providing growth opportunities, leadership training and job security. These are not bad things.

With that said, the hesitancy and low rates of vaccination among construction workers (as compared to other occupations) are likely to present some ongoing issues with labor shortages. We are not reducing our labor force but are further automating processes to reduce dependence on direct labor while re-assigning the labor that we have to increase production overall. In so doing, we are increasing efficiencies. Again, not bad things.

With a strong balance sheet and income statements, we have remained out of debt. And with some of the changes that the health crises precipitated, we will come through these times a better, more efficient company. Many others will as well.

Conclusion

Everyone is facing the same challenges: labor shortages, rising prices, and supply availability. Where you can stand apart is how you face and deal with those challenges. You never know … you, too, may find opportunities in the challenges ahead.MR

The opinions shared are those of the suppliers, and do not

necessarily reflect the viewpoint of Shield Wall Media.