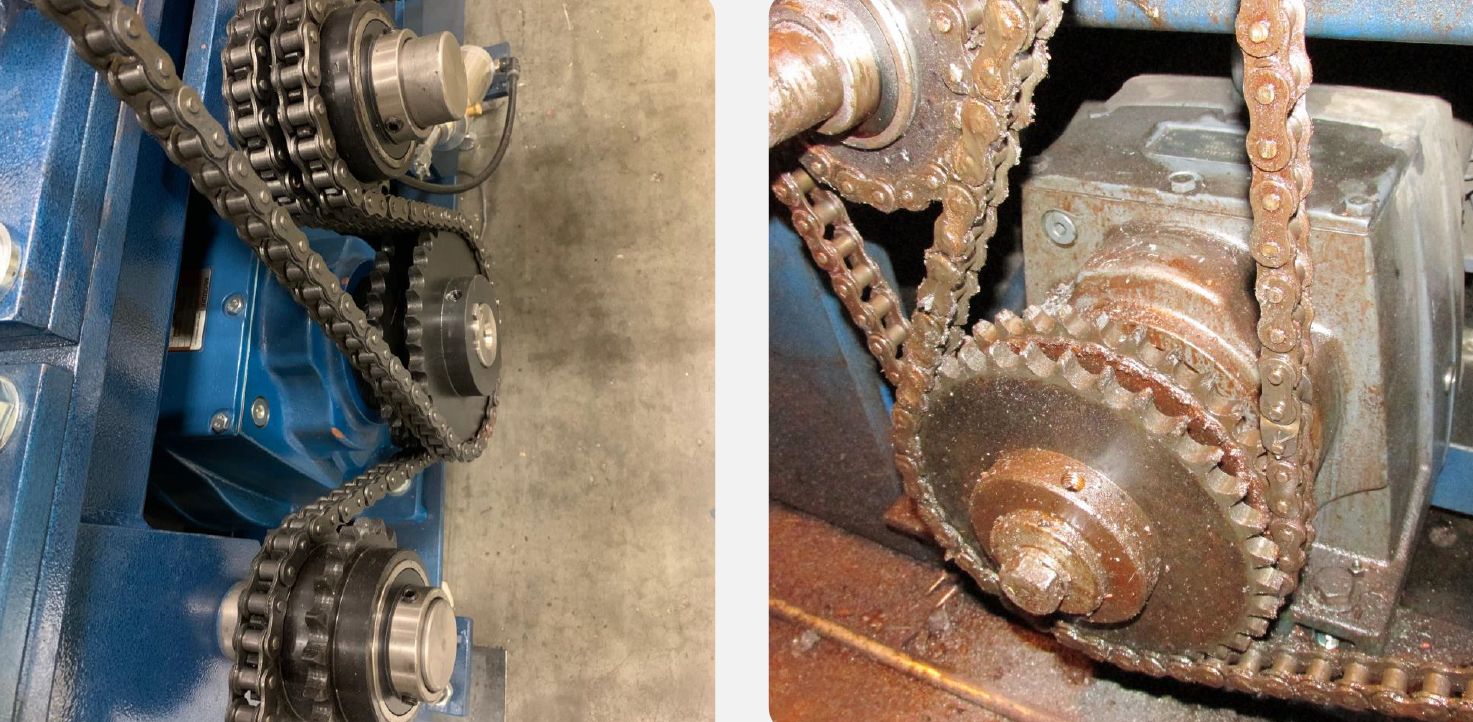

By Englert® Inc. staff

Regular, preventive maintenance is probably the single best thing you can do as a gutter roll forming machine owner and operator to keep your business humming and save money on repairs in the future.

Anyone who has ever had a gutter machine out of service and lost money on downtime and repairs will tell you: Don’t ignore preventive maintenance. The basics will keep your roll former healthy and give you a chance to catch anything serious before it becomes a major problem. All of this depends on you.

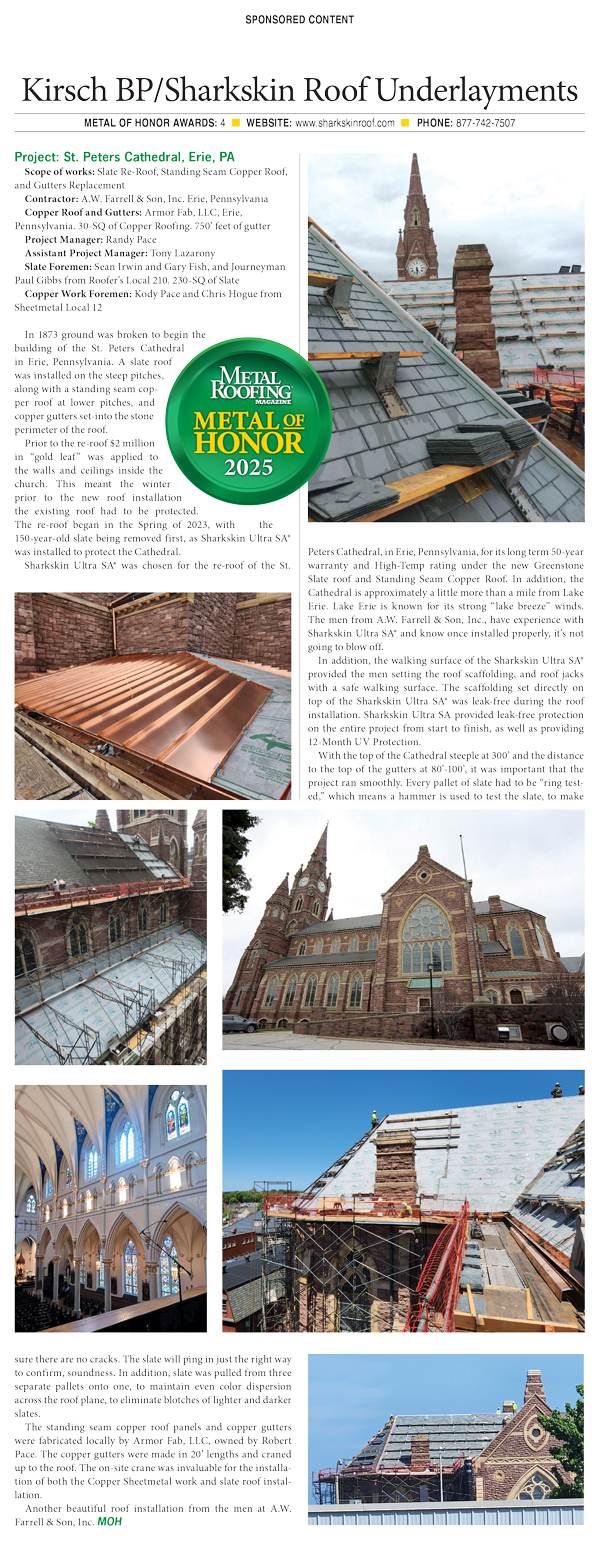

Every new machine sold in the marketplace comes with an operating and maintenance manual. We have had several gutter machines in our repair shop, ranging from one that was nine months old and looked like it had been in the field for 10 years, to another that was 10 years old and looked as good as the day it first saw service.

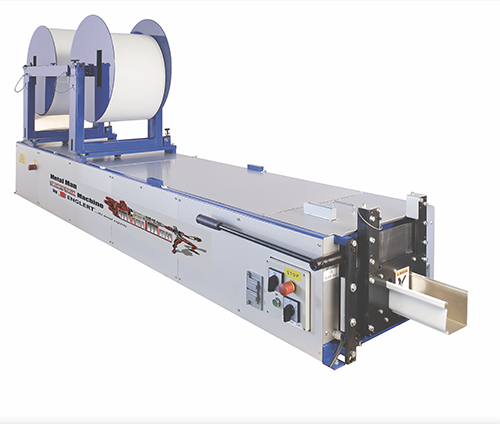

Maintenance Tips

If you’re serious about getting the best “mileage” out of your machine, follow these suggestions every month your machine is in service:

• Most modern gutter machines feature a polyurethane drive roller system with chromed free floating forming rollers that have to be routinely cleaned.

• Turn on your machine and spray the neoprene rollers with a product like Formula 409®, a household cleaner whose original application was as a commercial solvent and degreaser for industries that struggled with particularly difficult cleaning problems.

• Let your machine run for a few seconds, then turn it off and wipe down the rollers with a clean cloth. Remove as much dirt and grime as you can.

• Then turn the machine on and jog it forward—keeping your hands away from the machine. Turn the machine off again and wipe off the other sides of the rollers and the bottom roll. Wipe away any excess dirt or liquid. Repeat if necessary.

Once the neoprene rollers are clean, use a shop vacuum to clean out the rest of the machine and wipe it down with a clean cloth.

Use a clean cloth to wipe down the skate (metal) rollers with Formula 409. Cleaning these rollers may require more effort and “elbow grease” than the neoprene rollers. Repeat these steps once a month and remember to make sure the neoprene rollers are completely dry before running material through the machine. Rollers that are not dry will slip and make a mark on the bottom of the gutter material.

Wiping down the entire machine also gives you the opportunity to closely inspect it. As with any mechanized piece of equipment, keeping the machine clean at all times will increase its life and make regular maintenance easier.

Oiling the Gutter Machine

At least once a year, oil all of the chains in your roll former using motorcycle chain oil. The guillotine blade should be oiled every day with 3-in-1 oil. Do NOT use WD-40—it is not a lubricant. The WD stands for water displacement and the product is made with a cleaning and degreasing solvent known as Stoddard Solvent that can ultimately get sticky and gummy—not lubricating. It will create wear on the blade and not give you a good cut on the material.

Finally, two operating notes that can save you on repairs and machine malfunctions: If you are running your machine’s electric-powered motor from a wall socket or even a generator, use a 10-gauge, 15-amp extension cord. Anything less and the roll former may perform eratically.

And last, never leave material in any machine with polyurethane rollers. When you are done using the machine for the day, calculate the length of the machine into the last piece needed, and then empty the machine. Material left in the machine acts like a trough, catching dirt and debris. Consequently, when the machine is turned on, the roller runs through the residual dirt and will soil the product and the rollers.

This article first appeared on Englert Inc.’s blog and was reprinted here with permission. For more information on Englert Inc., visit www.englertinc.com.