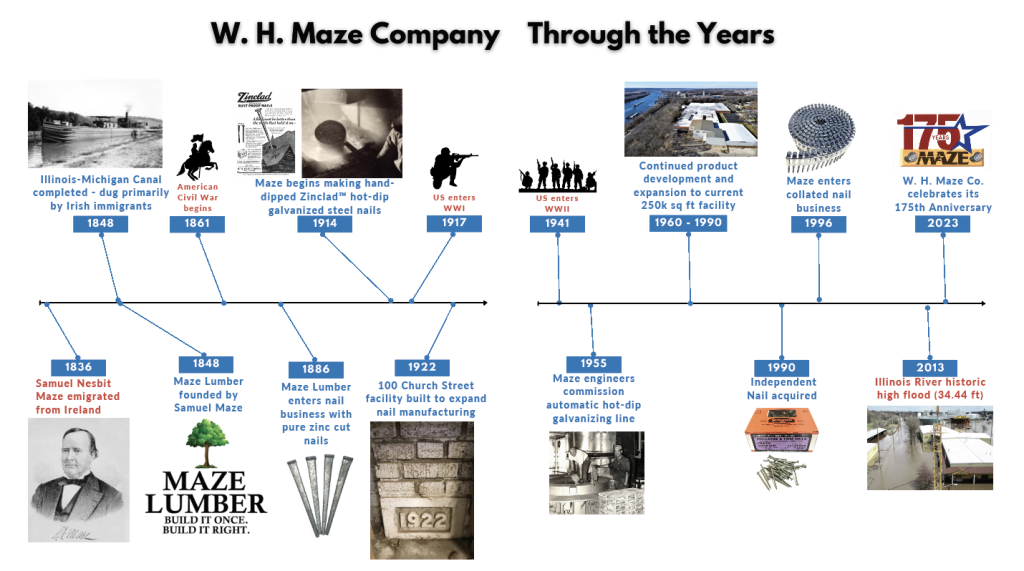

In 1848, just 30 years after Illinois became a state, Samuel Maze started his lumber company along the Illinois River. It eventually grew to include manufacturing the nation’s largest selection of specialty nails.

To this day, Maze’s company is still going strong. Maze Lumber is the state’s oldest lumberyard, Samuel’s great-great-grandson, Roelif Loveland is president of Maze Company – and the business is proudly celebrating its 175th anniversary.

“We have been blessed with many generations of great associates — both non-family and family employees,” Loveland said. “A huge part of longevity is having quality people….and the other part is having quality products that are continually demanded in the marketplace.”

“As my brother, Jim, said on the anniversary of his 150-year-old home in Spring Valley, Illinois, we are all simply caretakers of old businesses and old houses. It is our job to nurture them and make certain that they survive and thrive for the next generation. I’m very proud to be spending my years doing exactly that.”

He also said he is impressed by his ancestors’ ingenuity, which set up Maze Co. for longevity.

“It seems like entrepreneurship was the rule rather than the exception back in those days,” Loveland said. “Family-owned and operated store fronts and small businesses sprang up everywhere. The Maze boys were pretty clever fellows and built a very strong business for future generations.”

Over the years, Loveland said there have been steady changes to the family business.

For example, Loveland said nails were once made entirely of zinc purchased from Illinois Zinc and M & H Zinc. But in 1916 – during World War I, the price of zinc became so high due to its use in the war effort – Maze invented a method of taking steel nails and dipping them into molten zinc to give them a rust-protecting zinc coating. These nails were tradenamed Zinclad® – and they were soon being sold to lumberyards throughout the United States.

That was done by hand at first, but in 1955, Brothers James and Hamilton Maze designed a dipping machine to do the work. Those STORMGUARD® nails were actually double dipped – to greatly increase their longevity. Now homeowners had nails they could depend on to stay beautiful and rust-free for the life of their project.

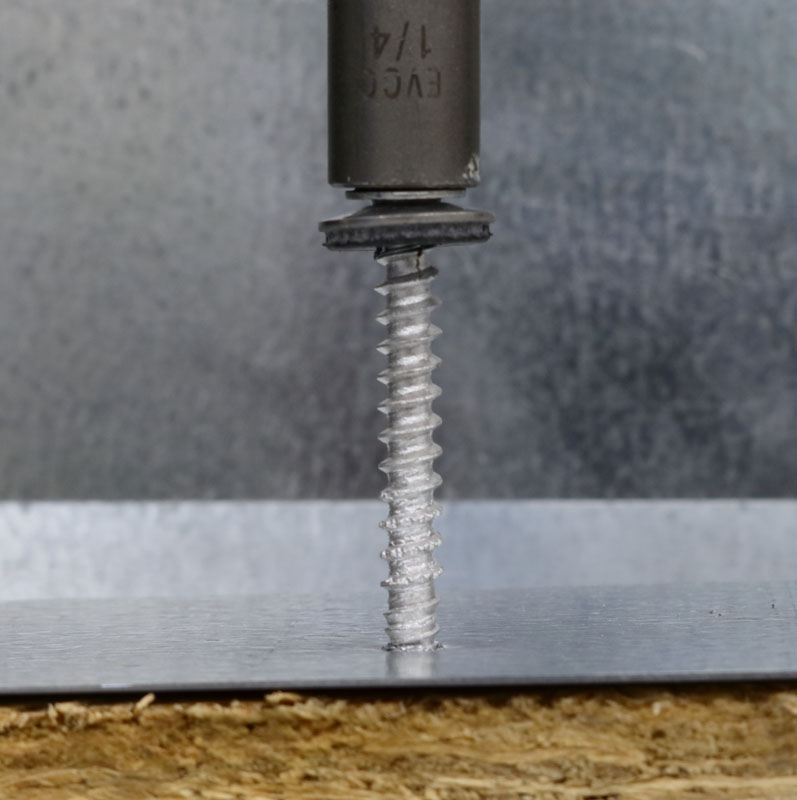

“The only thing that has stayed the same is that both types of nails were highly dependable and became demanded by contractors nationwide,” Loveland said. For example, Maze invented threaded nails – nails with ring and screw shanks – to really hold tight without nails popping back out on roofing, siding and decking. The Illinois manufacturing plant provides the construction trade with MADE IN USA nails that are hardened, plated, painted and collated – in many types of packages suitable for both builders and consumers.

And with 175 years in the rearview, Loveland said things will continue to evolve. “We continue to change with the times, including updating the products we handle at Maze Lumber and developing new nails that we manufacture and sell at the Maze Nail factory. We’re now looking forward to our bicentennial year!”