Project: St. Peters Cathedral, Erie, PA

Scope of works: Slate Re-Roof, Standing Seam Copper Roof, and Gutters Replacement

Contractor: A.W. Farrell & Son, Inc. Erie, Pennsylvania

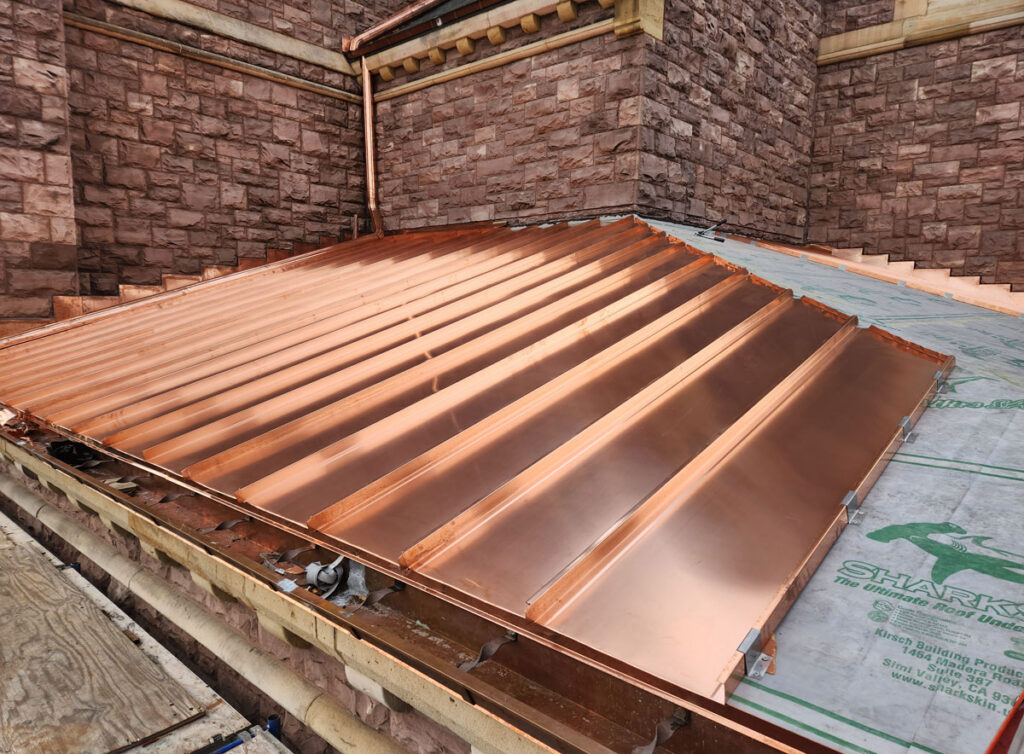

Copper Roof and Gutters: Armor Fab, LLC, Erie, Pennsylvania. 30-SQ of Copper Roofing. 750’ feet of gutter

Project Manager: Randy Pace

Assistant Project Manager: Tony Lazarony

Slate Foremen: Sean Irwin and Gary Fish, and Journeyman Paul Gibbs from Roofer’s Local 210. 230-SQ of Slate

Copper Work Foremen: Kody Pace and Chris Hogue from Sheetmetal Local 12

In 1873 ground was broken to begin the building of the St. Peters Cathedral in Erie, Pennsylvania. A slate roof was installed on the steep pitches, along with a standing seam copper roof at lower pitches, and copper gutters set-into the stone perimeter of the roof.

Prior to the re-roof $2 million in “gold leaf” was applied to the walls and ceilings inside the church. This meant the winter prior to the new roof installation the existing roof had to be protected. The re-roof began in the Spring of 2023, with the 150-year-old slate being removed first, as Sharkskin Ultra SA® was installed to protect the Cathedral.

Sharkskin Ultra SA chosen for long-term warranty and high-temp rating

Sharkskin Ultra SA® was chosen for the re-roof of the St. Peters Cathedral, in Erie, Pennsylvania, for its long term 50-year warranty and High-Temp rating under the new Greenstone Slate roof and Standing Seam Copper Roof. In addition, the Cathedral is approximately a little more than a mile from Lake Erie. Lake Erie is known for its strong “lake breeze” winds. The men from A.W. Farrell & Son, Inc., have experience with Sharkskin Ultra SA® and know once installed properly, it’s not going to blow off.

In addition, the walking surface of the Sharkskin Ultra SA® provided the men setting the roof scaffolding, and roof jacks with a safe walking surface. The scaffolding set directly on top of the Sharkskin Ultra SA® was leak-free during the roof installation. Sharkskin Ultra SA provided leak-free protection on the entire project from start to finish, as well as providing 12-Month UV Protection.

With the top of the Cathedral steeple at 300’ and the distance to the top of the gutters at 80’-100’, it was important that the project ran smoothly. Every pallet of slate had to be “ring tested,” which means a hammer is used to test the slate, to make sure there are no cracks. The slate will ping in just the right way to confirm, soundness. In addition, slate was pulled from three separate pallets onto one, to maintain even color dispersion across the roof plane, to eliminate blotches of lighter and darker slates.

The standing seam copper roof panels and copper gutters were fabricated locally by Armor Fab, LLC, owned by Robert Pace. The copper gutters were made in 20’ lengths and craned up to the roof. The on-site crane was invaluable for the installation of both the Copper Sheetmetal work and slate roof installation.

Another beautiful roof installation from the men at A.W. Farrell & Son, Inc. MOH