By Greg Moran, Sika Corporation

As a metal construction professional your number one deliverable is a quality installation that will withstand the test of time.

In most cases, the test of time can be 30-plus years, which means everything used in the job rides along with that guarantee. With this understanding, the quality installation of metal roofing systems must withstand years of weathering, continuous hot and cold cycling, thermal expansion and contraction, and environmental variables that include snow loads, hailstorms, rain and water exposures, UV exposure, and various wind loads. With these requirements as a given, one of the most challenging technical arenas is the understanding and selection of quality sealants and adhesives that match the required physical application needs.

Selecting the right sealant for an application goes a long way in reducing maintenance, callbacks, and quality issues reflected in your bottom line.

Metal roofing and metal construction systems contain numerous applications for sealants. The intent in using a sealant is to provide a boundary against air, moisture, dirt, dust, and debris.

Wherever steel roof panels or roofing accessories form an overlap or connective joint, form a frame or an opening, or meet up with architectural highlights like fascias, flashing, roof ridge or wall structures there is a need for a sealant. Likewise, wherever the roof surface includes a penetration, there is a need for a sealant. Examples include the joining of standing seam roof panels, both at the end laps and the standing seams, roof jacks, smoke vents, roof curbs whether for heating, ventilation, and air conditioning equipment or for skylight installation, roof ridges, and at any penetrations by mechanical fasteners. Typically these joints at the roof level are sealed with a butyl tape or a combination of butyl caulk and butyl tape.

Butyl tapes are normally made up of three components: rubber, filler (talc, plasticizer, etc.), and oil. Of these components, rubber percentage is the key ingredient. Rubber is what makes the product a better sealant. Why not use 98 percent rubber? It would cost too much, it would be more difficult to cut and manipulate, and the resulting material would be overkill for most applications.

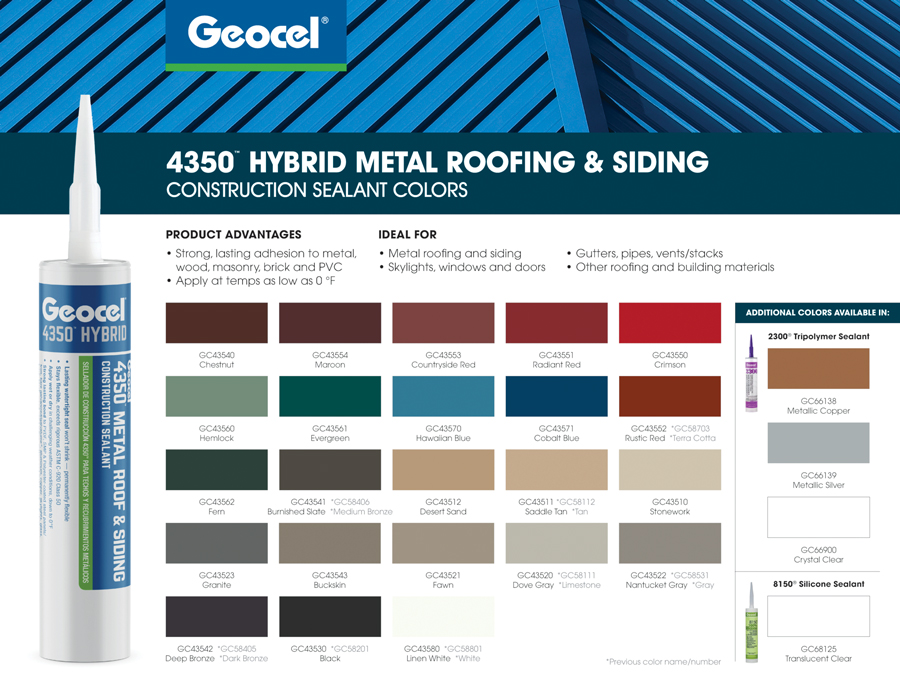

Miscellaneous exterior joints can be sealed with one-part polyurethane or silicone sealants. Typical examples include sealing fascia installations, gutter seams, window and door installations and trim, and flashings.

Adhesive systems are used on the building envelope to attach various accessories and to reinforce joints that are subject to stress. Many adhesives serve a dual role — they not only provide structural strength, but also an impenetrable seal.

Applications

Review the application requirements and the environmental exposure of the bonded product. Important data includes information on the material substrates involved, the surface properties, and their residing thermal expansion and contraction properties. In the case of metal roofing systems, remember that the entire roof system will expand and contract under thermal cycling conditions, not just the individual panels. Review the size of the joints, the application temperature extremes, and the environmental exposures. Sealant materials, which are exposed to the elements, will receive more direct punishment than those concealed under building materials.

You also want to be sure to review environmental conditions the product will be used in during installation — specifically the application temperature range. Metal construction works 12 months a year, and construction conditions vary within this timeframe. As an installer or specifier, make sure you select products that can still be used in extreme conditions.

Butyl caulks, hot melts and tapes

Butyl caulks and butyl hot melts are normally factory applied to the female seam of a standing seam roof panel, however butyl caulk is also used on site and in portable roll forming processes. For roofing applications be sure to select a pumpable or gunnable non-skinning butyl formulation to assure the sealant remains soft and pliable throughout the service life. This is arguably the most important criterion to understand as many products become hard and rigid after environmental exposure. Rigidity in combination with joint movement can lead to sealant failure.

Several easy tests to quickly analyze butyl properties exist. Cut about a foot section of the tape and roll it into a ball, then stretch it horizontally (or vertically) and notice how quickly it breaks apart and how quickly it recovers. Butyl tapes with a higher rubber content using higher-grade rubber will not break apart and will recover close to their original size. This difference is critical in applications where thermal expansion and contraction occurs. At the same time, check the webbing characteristics. Webbing occurs and is visible when the material is stretched. Good webbing is illustrated when the material stretches but stays intact. If this occurs, it will provide a good sealant barrier.

Next, roll a piece of each tape sample into a ball, holding it between the thumb and forefinger of both hands. Pull it apart about 1 inch then continue to stretch it apart very slowly while at the same time pulling down with your middle or ring fingers of both hands. What you are trying to create is a square shape of material that is stretched thin. You’ll be able to see how each product webs under extreme stress.

Likewise when selecting a non-skinning butyl caulk, or hot melt product, webbing is critical. To illustrate the webbing properties of different products, apply the product to two metal strips, squeeze them together and then slowly pull them apart. If the material stretches uniformly when pulled apart, it will do the same during thermal and stress cycles.

Wet sealants, adhesives

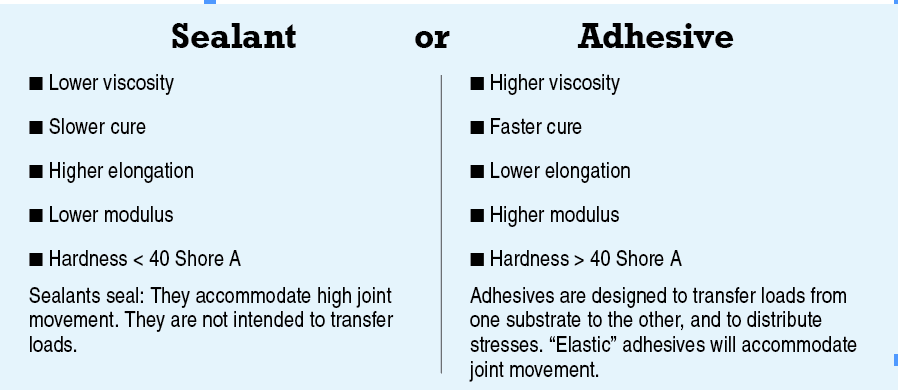

Within the wet sealant and adhesive product families there are multiple options, but also more opportunity for pitfalls. Again, the key to performance and longevity is selecting the right product. Review substrate materials, joint movement requirements (elongation), joint width and depth, and joint tensile strength requirements (particularly if the material is expected to add structural strength). Review product technical data sheets or specifications for key material properties including elongation, tensile strength, hardness ratings, and cure time. Generally, sealants are quantified as low viscous products, with a hardness rating below 40 Shore A, high elongation, and lower tensile strength ranging. Adhesives are normally high viscous products with a Shore A hardness rating of 40 or greater, lower elongation, and a higher tensile strength rating.

Chemical families for these products include latex, urethane, silane terminated polymers (STP), silicones, and acrylics.

Generally the use of any latex-based product is discouraged for metal roofing and metal building applications due to the performance aspects of both the building and the sealant.

Latex- and acrylic-based products are not commonly used in the metal construction industry, as the products generally do not meet the heat resistant requirements. Many polyurethanes and silicones offer excellent benefits such as strength, adhesion, and thermal expansion and contraction. Silane terminated polymer is a relatively new technology to the marketplace. These materials are solvent-free, have excellent strength, and offer resistance to color change when exposed to ultra-violet light. Butyl-based sealants typically offer adequate temperature resistance, adhesion, and thermal expansion for metal construction applications. It is important to understand the performance requirements of the building structure, and then choose a sealant or adhesive technology to complement the required performance.

Wet sealant and adhesive bonding analysis

The most obvious property characteristic question for sealants and adhesives is: does it adhere to the surfaces to be sealed or joined? There is however more to this equation than first meets the eye. When selecting a wet adhesive or sealant, it is necessary to understand the adhesive interfacial layer at the bond line based on the effects of environmental cycling. Although a material may bond at room temperature, this is not an indication of adhesion when subjected to elevated or freezing temperatures or after severe environmental exposure. This information is critical when determining the life of a bond-line.

There are several methods for testing adhesion; however, the most widely used and accepted is the peel test, which rates adhesion to a substrate after continuous exposure to a series of climates.

Following testing, a successful bond will show cohesive failure. When the material is peeled from the substrate, a mass of material is left behind, which indicates application was successful. Such failure indicates the adhesion strength to the substrates actually exceeds the cohesive strength of the bonding or sealing material. Therefore, don’t rely on peel strength specifications alone. Review the cohesive failure percentages for accurate portrayals of adhesion performance.

Summary principles

In summary, when selecting sealants and adhesives, key principles include the analysis of the application, joint design, joint performance requirements (sealant or adhesive), substrates involved, environmental exposure, application techniques, and expected performance longevity.

Understanding the requirements for your project is critical. Once this is complete you must fully understand the limitations of the sealant or adhesive and review the application and design in accordance with the suppliers instruction. Most manufacturers have recommended joint design and dimensioning guidelines based on extensive testing and expert experience.

If these simple principles are followed, you can expect that your work will stand the test of time, leading to more business and peace of mind. MR

Greg Moran is the market field manager for the Sika Corporation.

Metal Roofing Magazine was born as a supplement to Rural Builder magazine in 1999. A few more supplements were published in 2000. In 2001 it was elevated to a stand-alone magazine, and today it is over 20 years old.

If you have recently completed a metal roofing project on a historic building, we’d love to include it in the Metal Roofing IDEA Book. Don’t wait! The deadline is March 15. See page 52 for details.

If you have any questions related to Metal Roofing Magazine or the Metal Roofing IDEA Book, contact Karen Knapstein at [email protected] or 715-513-6767.