By Shannon Clark, MWI Components

Natural ventilation is like a symphony; one wrong note can stagnate the entire production, but when executed to perfection, the elaborate composition will rejuvenate the room.”

When it comes to ventilation, customization is the name of the game. You won’t find one ridge vent that’s perfect for each and every building; nor will you find a universal soffit profile. Obtaining ideal ventilation is a fine balance between ridge vents, soffit, and louvers.

Ventilation “Rules”:

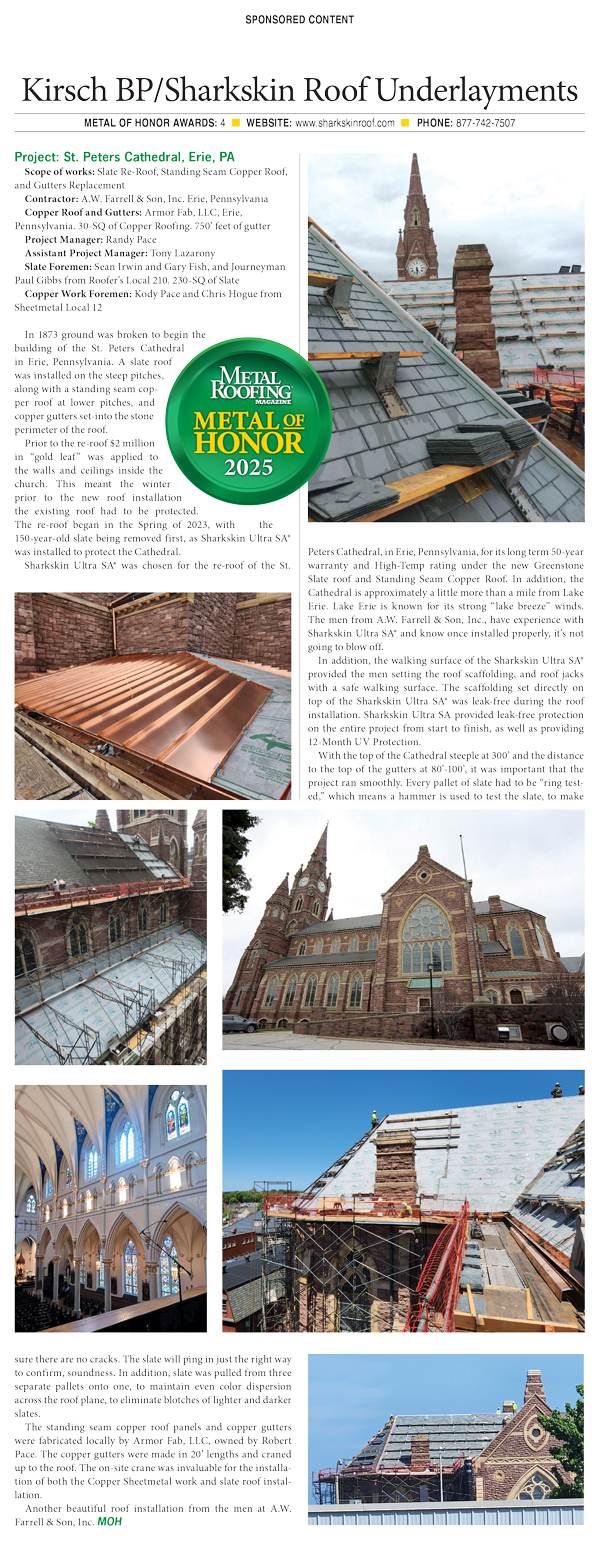

Photo courtesy of MWI Components

Systems using natural ventilation should be designed for effective ventilation regardless of wind direction.

Inlet openings should not be obstructed by buildings, trees, signboards, or indoor partitions.

Greatest flow per unit area of total opening is obtained by using inlet and outlet openings of nearly equal areas. If there is a difference in size, the lower opening should be slightly larger.

Two openings on opposite sides of a space will tend to increase the ventilation flow. If the openings are at the same level and near the ceiling, much of the flow may bypass the occupied level and be ineffective in diluting contaminants at the occupied level.

There must be vertical distance between openings for the temperature difference to produce natural ventilation; the greater the vertical distance, the greater the ventilation.

Now that you have a basic understanding of Natural Ventilation, take the time to evaluate a project’s ventilation needs by asking a few simple questions.

Important Ventilation Project Questions:

Are you ventilating the attic or the entire building?

What are the building dimensions?

What is the roof pitch?

How is the building used and how will it be occupied?

Is there insulation and where is it located?

What are the possible locations for air inlets?

Which type of ventilator will you use?

Choose Your Ventilation System

Upon determining answers to the questions listed above, be sure to align your answers with the appropriate ridge ventilation systems. Some manufacturers like MWI Components have ridge ventilation worksheets that allow you to determine the proper Ridg-Vent® for your building’s needs.

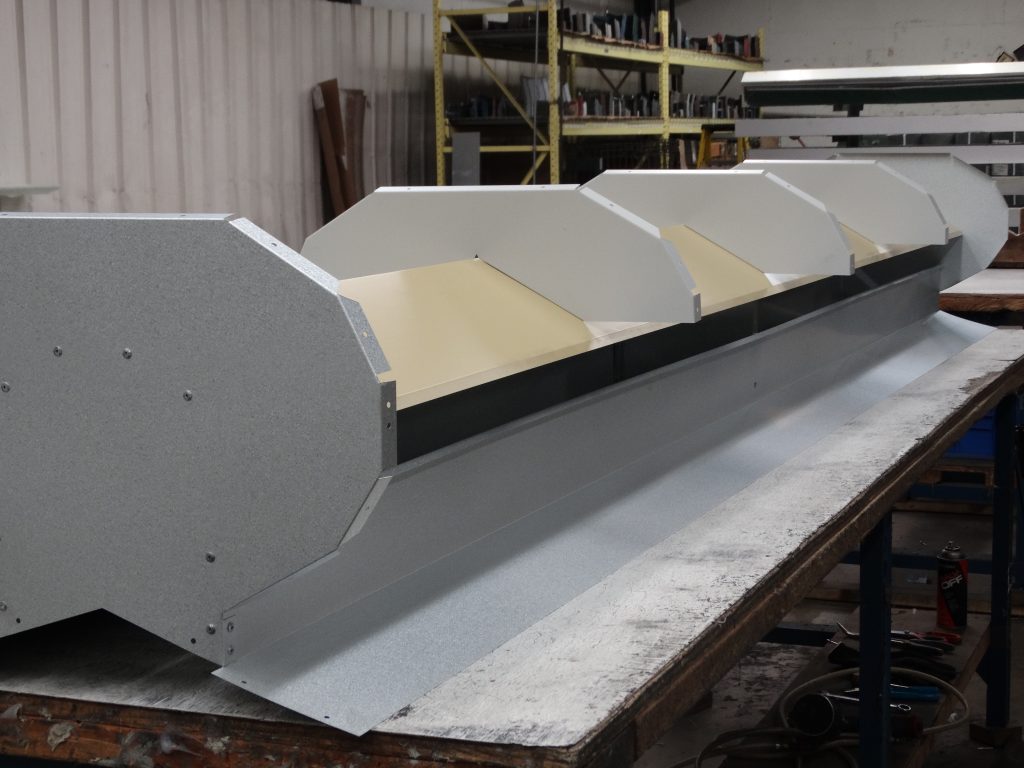

Different ridge vents will often be used on specific buildings. For instance, an RV100 Economy Ridg-Vent® from MWI Components is ideal for attic ventilation on garages, mini storage units, etc., while the MWI RV35 Ridg-Vent® is commonly utilized for large attic ventilation or entire horse, cattle, or poultry building ventilation. Consult your manufacturer’s ridge ventilation guide(s) to ensure accuracy with your ventilation systems prior to purchasing.

Above all else, for any ventilation system to function properly, an equal amount of fresh air must be introduced into the space to allow the vent to exhaust the air out through the ridge. Without an equal or slightly greater inlet area, no manufacturer’s ridge vent will function properly. In fact, improper ventilation will produce stagnant air. In some cases a lack of intake can even lead to a vacuum at the ridge as air is pulled in. This may result in water and/or snow damage.

Now Consider Soffits

Although ridge vents are a vital aspect of proper ventilation, soffit cannot be understated. The best location for inlet air or attic ventilation is through vented soffit panels.

Soffit inlets can also act as inlets for the entire building. It is important to match the intake to the exhaust in that application, as well. In the event that the intake and exhaust are not equivalent, a slightly larger intake than exhaust is preferred.

While soffit and ridge vents are crucial to ventilation composition, louvers and cupolas are often brought into question.

Louver and cupola Tips:

Be sure to note, the use of end wall louvers is only effective on short buildings where air can flow easily to the center of the building.

Although cupolas can be made with louvers, today’s cupolas are more commonly utilized for decoration rather than functionality.

All in all, natural ventilation perfection is achieved through a combination of factors. Understanding the basics of ventilation, answering simple—but necessary—questions about the project, and utilizing your manufacturer’s ventilation guides will result in a refreshing ventilation symphony that keeps your audience (even if it’s poultry) rejuvenated. MR

For more information, visit www.mwicomponents.com.