Let’s begin with a simple fact: Today’s technology makes routinely climbing a ladder and hand measuring the roof for a prospective job an unnecessary drag on your sales process and your business. Switching to remote, aerial measurement and imagery is an easy change that can save any roofing business meaningful time and money and improve the quality of your bids.

Depending on the distance you must travel and the size and complexity of the roof, rolling a truck to a pre-bid site visit can cost anywhere from $200 to $400. Regularly making these visits also siphons off your precious time, limiting the number of prospects you can quote and your focus on existing, paying work.

Routine pre-bid site visits and hand measurements also create an easy opportunity for human error. Maybe you’re in a rush, or maybe the customer is distracting you with questions from the ladder base. It’s not hard to miss a dormer or transpose a measurement. But, particularly in the metal roofing industry, a measurement error can lead to poor, margin-busting estimates, expensive bad cuts, additional site visits, and delays in job scheduling and payment.

Last on many minds, but perhaps most treacherous of all to your business, are the health and safety risks of climbing onto roofs when it isn’t necessary, and the potential liability associated with virus exposure to you or your salespeople.

The good news is that today’s aerial image technology can help you win business and avoid margin-chomping errors (for an example, see www.eagleview.com/newsroom/2020/10/waste-factor-forty-percent-dodecagon-roof). It can help you put your best foot forward without ever setting that foot on the property, much less on the roof.

Choosing Technology Wisely

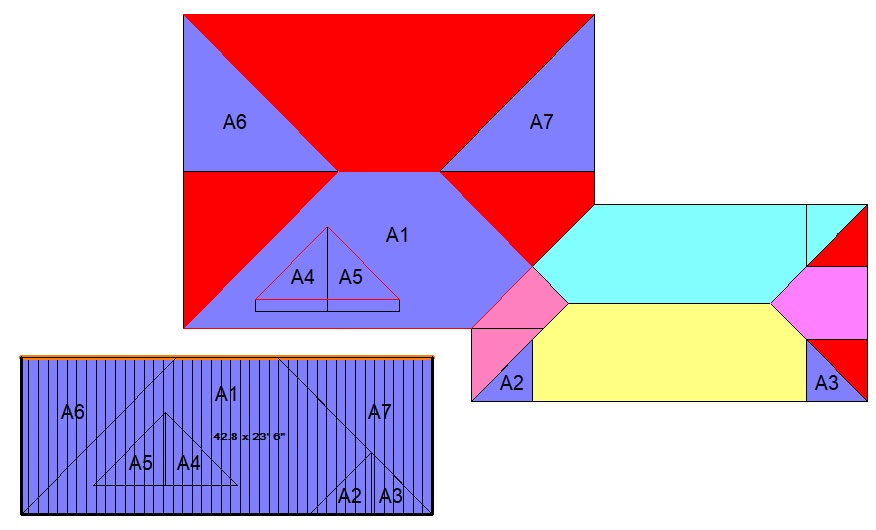

Which technology you choose—measurements derived from detailed images captured by specially equipped airplanes such as EagleView reports or lower resolution satellite images—will definitely impact the size and quality of your business gains.

Years ago, satellites offered some hope, but in reality, freely available, consumer-grade satellite imagery does not deliver critical benefits: resolution and timeliness. Having current, ultra-high-resolution images, captured by planes and readily available to roofers, is critical to deriving accurate measurements. Building changes happen all the time, and an older image may lead to inaccurate measurements that can mean hundreds or even thousands of dollars lost on a job, especially in metal roofing.

While satellites capture overhead (orthogonal) images, they do not offer true oblique or angled images from the North, South, East, and West. In short, you’re not going to get a 360-degree view of a property from a free satellite image. They also do not come with the creation of a 3D model to ensure that the measurements are correct and that each part of the structure is accounted for in detail. (See another example at www.eagleview.com/casestudy/proven-accuracy-outdated-imagery-inaccuracies.)

Satellite imagery can widely range in age, and 3+ years (which is not uncommon) is a large window of time for changes to occur, not only to the structure, but to what surrounds it. While satellite imagery offers 45-degree views that may appear similar to true oblique imagery, the building’s features cannot be measured using these views. Instead, that imagery is augmented by parallel projection, which distorts features in the distance, compromising the ability to measure. These distortions can throw off measurements by as much as 20%, which makes relying on this type of imagery for correct measurements of a structure another unnecessary risk.

Your measurements are the basis for your bid, and for material you order. Getting either wrong—especially in metal roofing endeavors—endangers your chances to win the job or have the correct materials on the job site, and your ability to make a fair profit and grow a healthy, thriving business.

Intelligent and Aerial Oblique Imagery

EagleView invented and pioneered the capture of intelligent aerial oblique imagery, and is the leading provider of imagery for local, county, and state governments. With more than 100 airplanes outfitted with extraordinary image-capture capabilities, EagleView routinely “mows the sky,” flying routes back and forth over upward of 98% of the population. These flights generate images, which we process with computer vision technology to create a constantly growing and refreshing library of hundreds of millions of oblique and orthogonal images.

These are then “stitched together” in patented processes to provide customers with incredibly detailed images that are 70 times more precise than satellite images with a 5 cm or better ground sample distance. Seriously, you could count the blades of grass if you had the spare time!

Metal roofs are valued for their strength and durability, from hurricane coastlines to hail alley to northern snow country. Despite the pandemic, the metal roof marketplace grew about 7% during 2020. A higher end roofing product, metal roofs are more environmentally friendly than asphalt roofs, last twice as long (or longer) and require little ongoing maintenance. And even though they can successfully be installed during all 12 months—allowing roofers four full seasons of business and better potential for keeping valued employees busy all winter—they remain a niche market. Many roofers shy away due to start-up costs and installation challenges.

Aerial imagery offers dramatic and proven suppression of the costs of acquiring work. In turn, roofers can make metal roofs less expensive and spur growth in this industry segment. As a higher end roofing product, it’s also worth meeting customer expectations of working with cutting edge professionals on the significant investment they are making in their home.