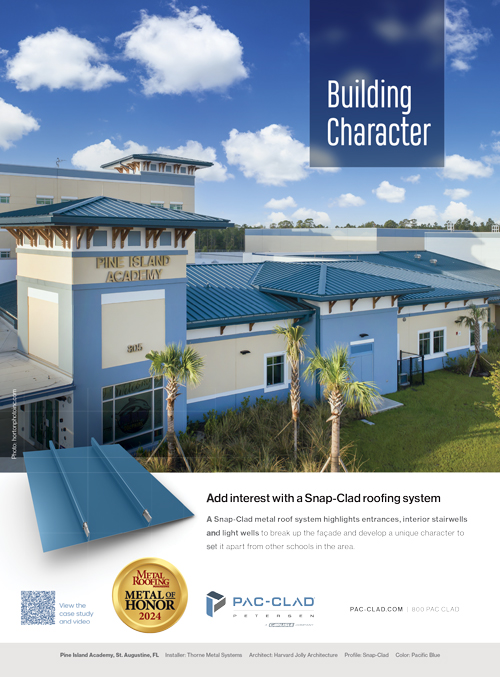

The latest roofing trends put a spotlight on sustainability, performance and aesthetic finesse. Against this backdrop, metal roofing panels top the list of viable options. Because metal roofing panels are available in a wide range of colors, profiles and widths, they can contribute to a sought-after aesthetic while meeting the performance criteria desired for today’s roofs. Their versatility in application makes them ideal for accommodating nearly any project design vision.

If you step back and think about how metal roofs are constructed, portable roll-forming machines allow roofing contractors to fabricate metal roof panels on-site. This equipment can be used to form shorter, smaller panels, which can then be used to create intricate sections of the roof. Often, these smaller panels are installed in a geometric pattern to create an eye-catching design. When you take a bird’s eye view of the project, these detail-oriented sections of the roof ultimately contribute to a statement-making exterior. What’s more, traditional decorative roofing elements such as cupolas, dormers, awnings and more can also be created with panels formed on a roll-forming machine.

Taking this on-site manufacturing approach saves the contractor a substantial amount of time and effort over cutting down prefabricated panels. Contractors who fabricate panels on-site can also adjust quickly and address any imperfections efficiently. This not only supports streamlined construction practices but can also contribute to increased customer satisfaction.

Bring the fabrication plant to the project site

Portable roll-forming machines are condensed versions of the equipment used at panel fabrication plants. These machines manipulate a metal coil with a series of rollers into the desired panel profile. Portable roll formers often include a shear or guillotine at the end of the machine that cuts formed coil into the desired length.

Decorative metal roofs. photos courtesy of Drexel Metals

Because this type of roll-forming machine can be mounted to a trailer and hauled to a jobsite and includes a decoiler and run-out table, it allows roofing contractors to form and cut panels to the exact length a project requires. The ability to fabricate panels with custom lengths helps solve challenges that can arise when intricate, decorative elements are a part of the roof design. Further, with this equipment, crews can fabricate and install simultaneously—as opposed to ordering material and waiting for its arrival. Due to the machine’s size, contractors with the proper lifting equipment can hoist them to roof decks, when required, to ease installation challenges.

Portable roll-forming machines are available in gas powered or electric options. They can include multiple profile rollers and a high degree of automation. With multiple options available, roofing contractors can invest in the equipment that best meets their business needs. Further, some metal providers offer programs that help roofing contractors invest in portable roll forming, train their crew on operation and provide proactive service plans to ensure a machine is running in its most optimal condition. These programs open the doors to the benefits of on-site fabrication to more metal roofing contractors.

On-site fabrication maximizes material usage

One of the most immediate benefits of on-site roll forming is that it allows metal roofing contractors to maximize their material investments. Because this equipment allows contractors to plan and fabricate panels to the exact length an application requires, it minimizes the need to cut and resize prefabricated panels. This is particularly beneficial on jobs that feature smaller, intricate roof sections that will contribute to the overall look of the project, or those that include more traditional decorative elements like cupolas, dormers, and awnings.

Creating any sort of ornate design element typically requires contractors to cut the roof panels to precise dimensions. This can increase wasted panel material as a poor or angled cut may require additional clipping to right the edge again. On-site fabrication allows contractors to form and cut the exact lengths they need for the intricate design elements to optimize the amount of material they use.

In terms of construction, this can reduce the bottom line in two ways. First, contractors who use on-site roll forming may not have to invest in as much material since they can maximize their yields with custom fabrication. Secondly, with less on-site waste, roofing contractors would not need to spend as much time and resources handling on-site clean-up and material disposal. Both benefits may increase profits and improve relationships with general contractors and project owners.

Portable roll-forming machines streamline construction

When contractors can form panel sizes to their exact measurements, they do not have to spend time measuring and cutting prefabricated panels. On-site roll-forming operators can program select machines to form and cut panels in batches, which increases efficiency and optimizes material use when constructing smaller sections of the roof. This capability can streamline installation through precision construction.

Further, contractors can use on-site fabrication to quickly rectify less than perfect installation. While no roofing contractor plans for jobsite mistakes, they are a possibility—especially for non-standard roofing components. If a roofing element does not meet the quality desired, roofing contractors can fabricate and reinstall on the fly since they do not have to wait for panel shipments. In conjunction with streamlining overall construction, this ability can help roofing contractors spot and fix any mistakes prior to a final punch list. This can increase quality and customer satisfaction to solidify a metal roofing company’s good reputation.

Investing in coil minimizes potential shipping damage and offers business opportunities

Portable roll forming also mitigates the potential for prefabricated panels to arrive damaged. The time lost while waiting for replacement material may delay project completion. This type of delay may lead to general contractors sacrificing the roof design element or removing a contractor from a project completely—both of which may negatively impact a contractor’s bottom line. Shipping delays might also cause a domino effect that leads to lost business or dissatisfied customers in projects other than the one currently affected.

Contractors with portable roll-forming machines can invest in coil rather than panels to sidestep this issue. This allows crews to work on their own schedule. Likewise, coil is easy to store, which reduces constraints and potential missteps when planning shipments around other subcontractors.

Further, on-site fabrication can support a cut and drop business model, which lets roofing contractors form and cut roofing panels for other contractors—without having to purchase materials or install them. Instead, a contracting company only needs to provide the roll-forming equipment. With this capability, contractors can specialize in creating panels for smaller sections of the roof or decorative elements, turning potential roofing competition into customers. This can generate income with a minimal crew and open the doors to more jobs by building a reputation for quality customizations.

Expanding what metal roofing contractors can offer

Portable roll-forming machines allow metal roofing contractors to have more control over their businesses. With this equipment, crews do not have to wait for prefabricated panels to arrive and do not have to plan, measure and cut materials. Further, these machines open potential business opportunities.

By being able to fabricate multiple profile types and panels that are the exact size needed for an application, contractors with portable roll-forming machines have a distinct advantage when bidding on work—especially since they are able to form smaller, custom roofing elements, which contribute to the visual appeal of the building. They can also become a manufacturer to bring in more business. Both options position a roofing company to take their business to the next level. MR

Brian McLaughlin is a graduate of Temple University and has been involved in the metal roofing industry for over 15 years. In his current role, he serves as the Director of Sales for Drexel Metals, A Carlisle Company. He has held many positions within Drexel Metals and has grown within the company and the industry as a leading expert in metal.