It Began Nearly a Hundred Years Ago

The parachute ripcord assembly first used by troops in World War II was designed by Arthur Justin Wasley, a Connecticut manufacturer who started off making door knockers and candlesticks. A great innovator, he owned Plainville Metal Works which specialized in the manufacturing of Early American and Colonial lighting fixtures, and custom lighting. As Brad Wasley, Arthur’s great grandson, puts it, “He succeeded using good old Yankee ingenuity, setting a tradition and philosophy that has remained with the company to this day.”

Arthur got his start with National Marine Lamp Company where he took on special lighting projects that he built in his cellar. His son Justin was a tool and die maker for lighting. Arthur’s flair for lighting design was well known. In addition to designing elaborate fixtures for many churches, his largest single chandelier was installed in 1960 in the Old State Capital building in Jackson, Mississippi. The chandelier was 350 pounds, 7 feet in diameter, 8 feet high and made of solid brass with 3,200 sparkling jewels and crystals.

Plainville Metal Works founded in 1926 was incorporated in 1951 to Wasley Products, Inc. With Arthur and Justin Wasley at the helm, they evolved the company to meet the needs of the day. One such need was for a new type of bearing seal, a metal stamping to which rubber was bonded. By the mid 1970s bearing seals and the precision rubber molded products line represented over 70% of company sales and they were a tier one supplier to the Big Three automotive and aerospace industries.

Upon Justin’s sudden passing in 1980, his son Alan A. Wasley assumed the leadership role of Wasley Products, Inc. Alan continued to respond to growing demands of customers and diversified manufacturing especially as competition from foreign products impacted business. The purchase of Precision Molding Company, Inc. and company restructuring birthed the current company, PMC Industries, Inc.

The 1990s marked the start of the now fourth generation involvement in the family manufacturing arena. Bradford A. Wasley, Alan’s son joined PMC Industries, Inc. As with generations prior, Brad gained his experience from the bottom up. He was responsible for the injection molding and seal business. Today he wears many hats as Vice President of PMC Industries, Inc. He is also Director of Total Quality, Quality Management & AceClamp Sales to name a few. PMC Industries, Inc. is an ISO 9002 manufacturer.

The injection molding business produced plastic snow guards for roofs. In the true spirit of innovation and through listening to contractors and installers, it became evident that there was a need for a new kind of clamp for standing seam metal roofs — a non-penetrating clamp. The Wasley team looked at various types of clamps out there and found what they were looking for in the medical field. Operating room table clamps used push-pin technology which they adapted in their design for metal roof clamps. These non-penetrating clamps can be used for attaching snow retention, lightning rods, signs, walkways, HVAC equipment, solar panels and more.

As AceClamp became a leader in the snow retention market, it became clear from listening to customers that they needed to be the one stop shop for all snow guards. The company, through rigorous third-party testing has developed snow-guard solutions for asphalt, slate, membrane, and concrete cover board roofs.

Today AceClamp offers snow guards for any kind of roof. Powder coating is available to color match snow guards to the roof. Custom solutions are offered in brass for copper roofs and historical buildings.

Challenges and Opportunities

It wasn’t easy bringing a new product into a market dominated by one player; the competition was fierce, but the team knew they had something great, and they persevered.

Brad said, “The product speaks for itself; it comes fully assembled, saving time and labor. The patented push-pin design provides equal torque and self-locks avoiding the problem of back out due to thermal expansion, wind flutter or seismic activity causing contractors to go back up on the roof to retighten clamps.”

An industry trend that poses a challenge, according to Brad, is metal roof panels becoming a thinner gauge or a short wide seam in the name of economy. If you get much above 26 gauge, the metal panel does not have the strength to hold solar panels and it’s hard for clamps to “bite” into them.

Greg Prentiss, the company’s sales engineer said, “Pick your roof wisely. If you are looking to put snow retention or solar panels on it, you have to have a decent roof. A clamp is only as effective as the material it clamps.”

On the other hand, there are many opportunities in the market. Don Peronace, Marketing, said he has not seen much of a slow-down in new housing. “With the hurricanes and strong weather, we are seeing metal has proven to be a viable choice.”

Brad Wasley

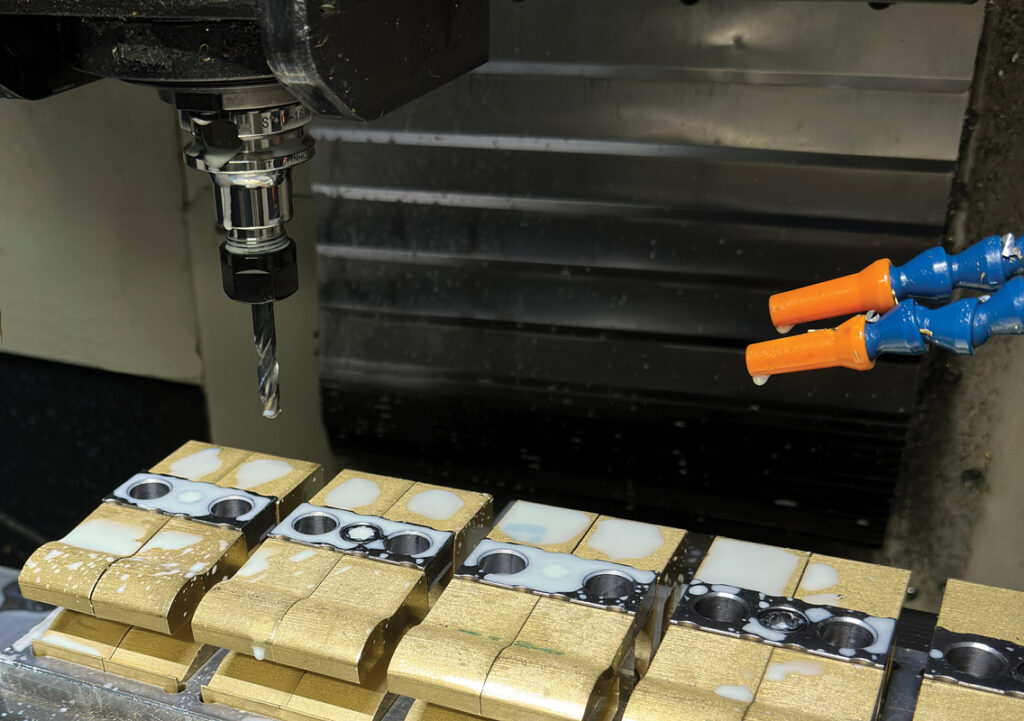

Custom brass clamps for use on a copper

standing-seam metal roof.

Collage, upper left clockwise: Sadie, Morale Officer, Marvin Curtis & Jennifer Steinman, Manufacturing;

Ray Almodovar, CNC Operator; Natalie Passalugo, Sales Administrator; Dan Burger & Tamas Kovac, Engineering. Photos courtesy of Ace Clamp.

High Tech Workplace, Family Culture

The company will be celebrating its centennial anniversary in 2026. One hundred years is a long time to be in business, and this company strives to stay true to their founder’s business model, using that good old Yankee ingenuity Brad mentioned. That means keeping up with the newest technology and continuing to listen, learn, and innovate, while not forgetting their history. They have a museum on campus showcasing their innovation in manufacturing and nurturing company pride in almost 100 years of manufacturing.

The company mantra is “Always come to the table with solutions, not problems,” a mindset verbalized by Brad’s dad and referenced in the AceClamp logo, “Innovative Roofing Solutions,” Peronace added.

PMC Industries, Inc. employs over 60 people. Many employees have a long tenure and there is very low turnover, which speaks volumes to the company culture. Brad attributes this to an employee-centric culture in which everyone is treated with respect. That family feeling is nurtured through events such as cookouts, visits from a variety of food trucks and always a favorite, free ice cream days when the ice cream truck comes to campus. The annual holiday gathering celebrates the contributions each employee has made and an opportunity to express our appreciation, Mary-Jean Wasley said.

Employees show their appreciation by finding many of the company’s new employees, inviting family and friends to apply. There is no rule against family members working together; management makes it clear that any family disagreements are not welcome in the workplace, and people respect that. Hence you have son working for father, cousins working side by side, etc.

Employees are further encouraged to help each other out and work productively together. In the spirit of continuous improvement, there are monthly goal incentives that motivate everyone to work as a team in order to meet and exceed customers’ expectations.

Ace Innovation

The company plans to continue listening to customers and bringing solutions to the table; that is what they do, whether it is saving Disney’s “Space Mountain” ride by supplying the bearing seals or finding a solution to the most complex rooftop solar installation. Their newest and most robust clamp recently solved a California solar project installation. MR