By Linda Schmid

Raymond Zimmerman worked for his father making ferrules for Quaker State Metals until his father passed in 1968. Then Zimmerman took over, stepping up ferrule production. In 1973 he named the business Raytec and began learning how to run it, from accounting to marketing to product development…Raymond was ambitious; he wanted to produce other products besides ferrules.

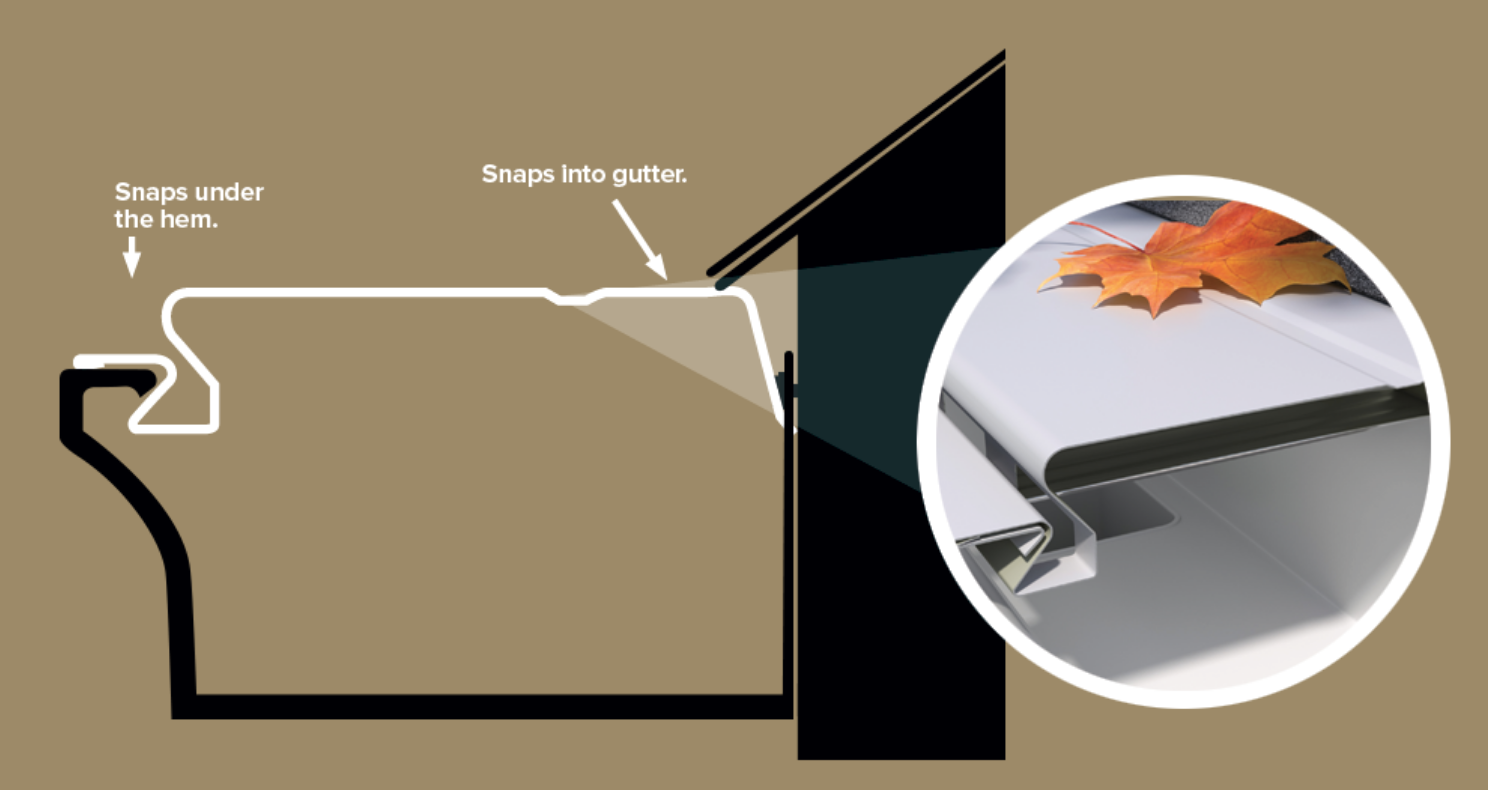

Starting with what he knew, farming, he developed the Herdex, a manual record keeping system for dairy cows. Over the years, Zimmerman developed more and more agricultural products, but big growth came when Zimmerman saw a need for an improvement on the easier to install gutter hangers that other companies had introduced to the industry. Gutter installers liked the idea, but found that these hangers were not very strong. That’s when Zimmerman, who had experience in metal forming, created the Hangtite hidden gutter hanger. It looked small, but it was made of a very strong alloy.

Zimmerman sent his Hangtite Hangers out to installers and they began asking for them from their suppliers. Every year Raytec sold more hangers and fewer ferrules. Then his team developed Hangfast, which is a version of HangTite that uses a screw, and sales expanded even more.

Today

Today the company’s products are available through major supply companies. Raytec ships them from their plant in Missouri across the country and around the globe to … basically anywhere it rains! They serve residential construction with gutters and gutter accessories and roof flashing, as well as agricultural products for smaller family farms and custom fabricating for anyone who needs metal parts.

Its headquarters are located in Ephrata, Pennsylvania, and the company consists of fewer than 50 employees between Missouri and Pennsylvania.

Culture

Lancaster is a conservative Mennonite community with an old-fashioned work ethic according to Tag Saunders, Director of Sales Marketing. The company is a nice place to work he said. It’s a family company and they really care about their employees.

“You can feel it. And, even when it’s time to retire, most people don’t want to leave,” he said.

Maybe people are reluctant to leave because of the company’s attitude about work: “Work hard and you will be rewarded,” Saunders said. But don’t forget why you are working. Come dinner time, go home to your family.

It’s rare that there are job openings, but the jobs that do open up are usually quickly filled by an employee’s family member or friend, or another member of this tight-knit community.

Challenges

The pandemic created challenges for most companies and Raytec was no exception. There was such a spike in demand for building products and they had to determine how to handle it. They knew that the demand was artificial (not real growth) so they wanted to ensure that they were loyal to their existing customers, fulfilling their needs first. This meant that there were times that they had to deny new business.

Then there were the rapidly changing material costs. Saunders said it forced them to be agile so they could quickly adjust pricing as necessary.

However, good things came out of the situation, for it taught them to be more efficient and between 2019 and today, they have almost doubled their production capacity on their gutter hangers, and they are more competitive on pricing than ever.

Of course, now they, along with the rest of the industry, find themselves navigating a somewhat slowing economy.

Results

The company is glad to be known for quality products and excellent customer service. They are constantly looking for ways to deliver value — that is, to deliver more than the customer has paid for. It’s not just business to the team, it’s a feeling of personal satisfaction when the customer is happy and enjoys doing business with them.

Saunders’ best advice to achieve this feeling is: Don’t cut corners, work hard, treat people right, and good things will happen.

Anticipation

A new product will be joining their lineup: a mesh gutter cover in stainless steel, a counterpart to the aluminum mesh cover they have.

Beyond new products, Saunders sees a constant string of challenges. At the beginning of each new year for the last 3-4 years, management has faced new challenges and every year turns out great. So challenges are good things — as long as you turn them into opportunities.

The Old Ferrule Machine

Paul Zimmerman didn’t realize that winning a contract to make ferrules from his father’s small steel fabricating company was the first step in a journey to establishing Raytec Manufacturing. Paul was ill and needed some way to support his family. The ferrule contract was the ticket. The family made a penny apiece on ferrule production.

Ferrule and spike is the traditional way to hang gutters. The ferrule is a tube through which the spike was driven, maintaining the integrity of the gutter and keeping it from collapsing.

This ferrule-producing bench required a metal blank to be placed in the slot, then the operator manually cranked it until the ferrule was formed. It was fairly easy to use once you developed a rhythm. In fact, the whole Zimmerman family spent time on the machine making ferrules.

Some gutter installers still use spike and ferrule today. People who have been doing it this way their whole lives and some young installers think it’s stronger than hangers, said Tag Saunders, Raytec’s Director of Sales Marketing. However, the company discontinued this method of production back in the late 1970s or ‘80s. Now Raytec has a fully automated sheet metal line with benders to process 12-foot pieces, cut them, and the finished pieces roll off the line.

“Such a contrast in technology,” Saunders said. “It’s really not that long ago that this old machine was the sole production process we used to make ferrules,” he added.

MR