Panel Clips and Cleats 101

By Andrew Mullen, Direct Metals

Metal Roofing Panel Clips…What Are They?

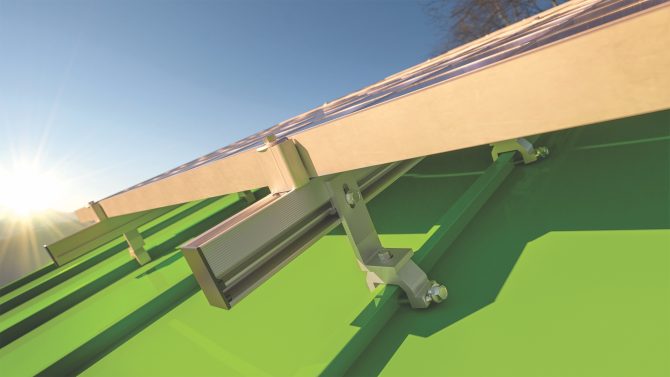

A panel clip is the common way that many concealed fastener metal roofing panels are secured to a roofing system substrate. The selection and installation of the proper panel clip and screws have a direct effect on the performance of these systems. Understanding how a panel clip is chosen and performs within the roofing system is an important component of being a professional installer. It is important to have the correct fit for the panel with adequate fastener relief and enough clamping surface to provide the holding powers that the installation environment requires.

Many factors affect the performance of a panel clip, including width of the clamping surface and the gauge of the metal. Development of light-duty and heavy-duty choices have given installers and manufacturers many options to find the right mix between budget and performance. Nail strip concealed panel fastener metal roofing systems have become popular—these use a nailing flange and extra low-profile wafer head fasteners to install without the use of a panel clip. Most of the other concealed fastener panel clip systems require panels clips and fall under the categories listed below.

Snap-Lock Standing Seam Systems:

Popular with on-site rollformers, snap-lock panel systems provide continuous thermal expansion and suit applications from awnings and residential homes up to 1¾” tall commercial applications. Snap-lock panel clips range in thickness from 24 gauge up to 18 gauge and are 7/8″ to 115/16″ in height. Snap-lock panel clips are typically available in light-duty parts that are 2″ in width or heavy-duty parts that are 3″ or 3½” in width (increasing the clamping area on the panel and allowing for higher performance or wider clip spacing). Because the snap-lock clip is not “seamed” to the actual panel and instead hooks over the male leg and supports the underside of the panel with a tongue, it provides infinite thermal expansion while at the same time being a fixed clip.

Mechanical Lock Standing Seam Systems:

Mechanical lock panel systems use four different types of panel clip or cleat systems: a fixed panel clip, an expansion panel clip, a continuous cleat system, or a batten seam clip system.

1. Mechanical lock fixed clips:

A fixed clip mechanical lock system such as the popular 1½” mechanical lock panel can be hand- or machine-seamed to a 90- or 180-degree seam. This creates a system similar to a one-piece continuous monolithic roof. It is very strong and delivers excellent value. Fixed panel clips for these systems range from 26 gauge to 22 gauge in thickness and 2″ to 6¼” in width. Fixed panel clips are typical used in runs of less than 25′, due to the challenges that thermal expansion can present to a fixed panel system.

2. Mechanical lock expansion clips:

Expansion panel clips are known by many names: sliding clips, slider clips, expansion clips, two-piece clips, and float or floating clips. These panel clips are comprised of a base and a top section that work together to allow for expansion and contraction (thermal movement) of the panel system. These clips are quite a bit more expensive than a fixed clip and typically involve a heavy base such as 16 or 18 gauge and tops in 26, 24, or 22 gauge. Some of these clips may come as two parts that need to be assembled on-site, while others are one-piece expansion clips that come assembled.

3. Mechanical lock continuous cleat system:

This system is not a popular method, but you do see the use of a continuous cleat in edge zones in high wind areas. A continuous cleat is typically formed with a hand brake and is not punched in a press as most of the panel clips mentioned above are.

4. Batten seam panel clips systems:

These batten seam systems, also known as snap cap or snap-on batten systems, use a fixed “batten” clip that secures two 90-degree male leg seam panels together and at the same time, secures the separate snap-on cap with the wings or ears integral to the clip. This system is typically used on mansards, fascia, or other architectural details and can be curved into a radius panel. Batten panel clips are typically found in light gauge metals such as 26 and 24 gauge in 2″ widths.

What Regulations Are

There on Panel Clips?

The regulations are mostly governed by the panel clips that were tested with the manufacturers’ panel system. Many testing reports will clearly identify the size and gauge of the panel clip to be used. Some systems are UL Classified and fall under those ratings, and some building codes spell out specific requirements for panel clips and panel clip fasteners. One such example is the 2017 Florida Building Code 1506.7 and the 2020 Florida Building Code R904.5.3 requirement for metal roofing panel clips that sets standards for minimum corrosion resistance of the panel clip materials.

These requirements have promoted the manufacturing of specification-specific panel clips made from virgin steel coil. This is contrary to some previous practices of using drop or secondary excess coil to produce panel clips in regulated areas or states. MR

Direct Metals Inc.