Snap-Z’s Mindset for Success: Keep paying attention and keep learning.

How It Began

In 2001, Manny Glick began installing metal roofs, and in 2013 he started Glick Metal, producing standing seam roofing components. He used a New Tech roll former and a Variobend brake to create standing seam metal. Manny was bringing his machine to job sites and manufacturing the panels, thereby avoiding the usual problems attendant on packaging and shipping, such as damaged panels and late deliveries.

The interesting thing when you immerse yourself in an industry, you hear about the challenges people have. Manny heard complaints about ridge vents, and he began looking at the options, soon realizing that the products on the market all had drawbacks including trying to cut them to size on the jobsite. That got Manny to thinking…maybe he could solve that problem.

He started experimenting with his CNC folder. He wanted something that would be ready to go for the roofer, easy to install and would do a good job of venting the metal roof without letting rain in. After about a dozen designs, he had it, and Snap-Z was born.

Of course, the product had to be tested. At a TAS-100 facility his Snap-Z Ridge Vent was tested for rain and driving snow with gigantic fans that generate hurricane-force 110 MPH winds blowing water around. This test was instrumental in attaining approvals in states with more stringent criteria. The sales representative got to work and soon they had thousand-piece orders. Once salespeople from suppliers got wind of this new product, they wanted to sell it, then post-frame product distributors began calling the company.

“We pre-cut these vents,” Manny said. “There’s no cutting for the contractor anymore; they just snap it in at the exact length they need. They are probably saving time and labor costs of 50%. Plus the external fasteners necessary for other products can create all kinds of divots in the metal.”

Manny Glick, President

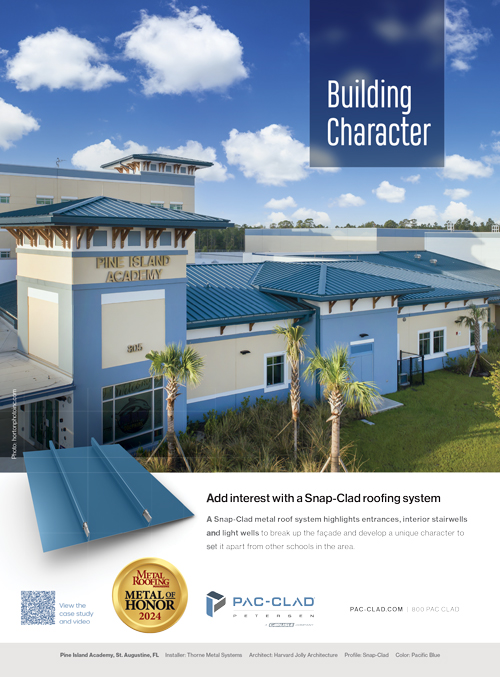

The Snap-Z manufacturing facility, Great Falls, Montana. Photos courtesy of Snap-Z.

Snap-Z was awarded its 10th Metal of Honor award in 2025.

Chris Glick is a Snap-Z Salesman and Volunteer Firefighter

How It Grew Into the Business It Is Today

The company did very well in 2015, and they really ramped up sales and marketing efforts in the years that followed, streamlining the manufacturing process, and bringing in new people to handle the load. The Snap-Z vent was recreated in sizes to fit all standing seam heights, expanding the product’s usability and customer base.

Metal coil is supplied by Liberty Painted Products, and to keep up with production Snap-Z is now roll formed with a custom roll former, said co-owner Chris Glick.

The company accomplishes distribution through dealerships, which can include anyone that has a roll former and a brake. They have dealers in all 50 states including Alaska and Hawaii. With many distributors and customers in every state across America, the company has grown significantly. The goal is customer service and product availability.

Challenges and Lessons

As for so many, the material shortages during the COVID-19 period were some of the company’s most challenging situations. However, Chris said that one way or another they were usually able to come up with the materials their customers needed. Though their delivery was slower during that time, they have loyal customers who did not desert them…after all, everyone was in the same boat.

Chris doesn’t see the rising costs of materials as a problem because, just like the COVID-19 supply shortages, it will affect everyone.

Employee acquisition has not posed much of a challenge, as Chris said they always try to look ahead at what is coming and plan for enough resources ahead of time. Sometimes that means hiring a little more heavily than is needed at the moment, but it has always proven the better option than waiting until they are overwhelmed and then trying to get employees in the door, trained, and up to speed instantaneously.

Employee turnover has been very low. “The trick,” Chris said, “is to find out what motivates your employees. It is pay for some people, a positive environment for others, still others may need to be left alone to do their job and not feel micromanaged. But keep them informed and listen to their ideas,” he advised. “The employees are in the shop every day seeing the quirks in the system, and if they can improve it, I let them do it,” he added.

It seems the company has not been overly challenged by any circumstances, but perhaps that is just the company mindset. Chris tells people, “If you make a mistake, apply whatever lesson you learned and move forward.” He encourages people to “Be forward thinking, keep paying attention, and keep learning.”

Culture

The culture, Chris said, is professional, yet relaxed and open. The business is small, employees work hard, they are very knowledgeable, and they all pull together and help each other out.

The company’s mission is to provide great service. Service can be as simple as answering the phone; replying to emails in a timely fashion, and making yourself accessible to customers; striving to get shipments out promptly and providing tracking numbers. Place your emphasis on the doing rather than the talking Chris advised.

Looking Ahead

“The future of the metal roofing industry is wide open and it’s very exciting for the metal industry,” Chris said. “Metal roofing is a better option than some of the roofing available. It’s lightweight, environmentally friendly, energy efficient, and it performs better in a fire. It usually achieves a Class A fire rating.

“California’s wildfires have the potential to reshape the industry. You hear of a push in the West for fire-resistant products to be required,” Chris said. 1

As the metal industry grows and gets more market share, Chris plans to grow the company along with it, continue to develop and improve their product. MR

1 Currently, the International Wildland-Urban Interface or aspects of the code have been adopted in nearly 200 jurisdictions across 24 states and at the state level in Montana, Nevada, Pennsylvania, Utah, and Washington, according to the International Code Council.