We recently discussed the technology of forward-looking infrared and how roofing contractors can use thermal technology to offer inspection services. John Anderson, Product Manager of Security Solutions for FLIR Systems, shared his knowledge here:

Roofing Technologies (RT): Let’s start with the basics. What is thermal imaging and how does it work?

John Anderson (JA): Normal, human vision is limited to a very narrow, “visible” band of the entire electromagnetic spectrum. The infrared spectrum, also called thermal energy, has a longer wavelength than visible light. A thermal imager/camera is essentially a heat sensor that is capable of detecting tiny differences in temperature, both hot and cold. Thermal imaging cameras enable anyone to see thermal energy (heat), essentially giving the user superhuman sight. With thermal imaging, the portion of the spectrum we perceive is dramatically expanded, helping us “see” heat even in the absence of light.

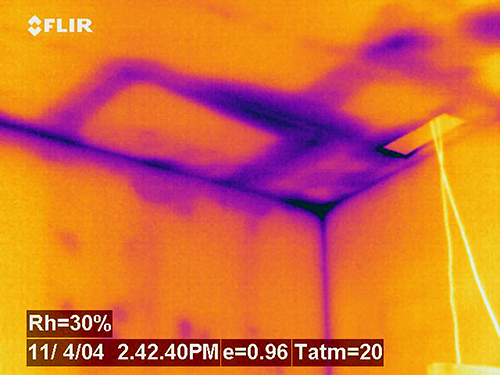

Everything in the known universe emits, reflects, or absorbs thermal radiation. A thermal camera converts the “heat” data it measures into visible images. In addition to seeing in the dark and detecting invisible heat sources, the thermal technology helps users see through fog and smoke. The image produced is known as a thermogram and is analyzed through the process of thermography.

Putting Thermal Technology to Use On the Job

RT: How can this technology be used by roofing contractors?

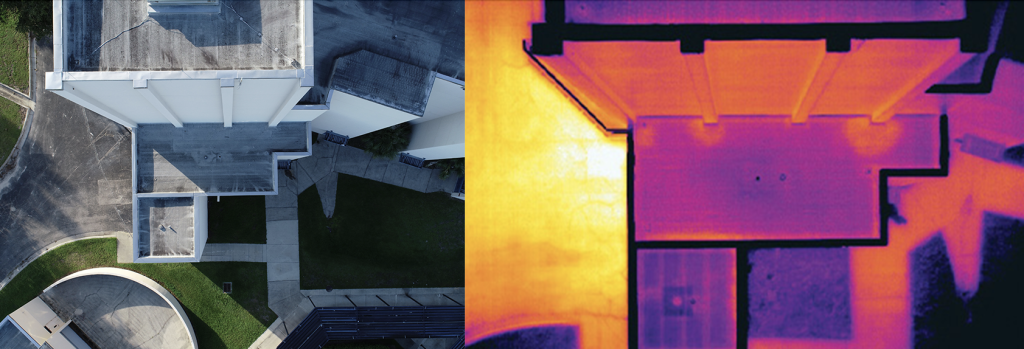

JA: Thermal imaging is a popular nondestructive inspection technique used within the construction trades. If a flat roof experiences a leak, damage typically goes unnoticed as water penetrates and soaks the decking and insulation over time. Rot often develops, which can weaken the roof structure and lead to expensive repairs down the road. Given how difficult it is to find a water leak with the naked eye, thermal cameras can help roofing professionals pinpoint water intrusion, find moisture beneath the surface, and document dryness with accuracy and confidence. As thermal imaging is much quicker than visual inspection, it allows inspectors to focus on the whole roof, not just the at-risk areas. It also permits nighttime and shadowed area inspection, as it does not require visible light.

RT: What are the limitations of forward-looking infrared? How can one produce the most accurate results?

JA: There are a number of factors that can affect the performance of thermal cameras and ultimately the outcome of an inspection:

• While a thermal camera can quickly identify potential moisture issues, it is recommended to also confirm/verify the issue with a moisture meter.

• Thermal cameras come in a variety of resolutions, therefore, different cameras have different limitations. A lower resolution camera will require the operator to get very close to a potential problem area to pinpoint an issue, whereas a camera with higher resolution will provide greater detail and clarity throughout an inspection. However, higher resolution cameras generally cost more than lower resolution, so the operator will have to consider what resolution is best for their needs depending on when, where, and how they plan to use the device.

• Thermal readings may be affected by interior heat sources or differences in insulation thickness.

• The optimal time for scanning a roof, often referred to as the “thermal window,” occurs when the roof is either warming or cooling, usually early- to mid-morning and then again shortly after sunset. Ideally, most roof inspections are conducted shortly after sunset during a cooling stage to avoid daytime shadowing and solar reflection issues on the roof.

Furthermore, the best time to conduct thermal imaging roof inspections are when there is high contrast between the air temperature outside versus inside the building. This makes it easier to spot potential anomalies. It’s also best to avoid inspections on windy days, as the wind and pressure changes associated can make it difficult to pinpoint issues. Meanwhile, excessively sunny, warm days can create solar loading effects on the roof that could mask problem areas.

Choosing the Right Device

RT: What types of infrared products are best for roofing contractors just starting with this technology?

JA: While handheld thermal cameras have been used by roofing professionals for years to pinpoint water intrusion, find moisture beneath the surface, and document dryness, the job is time-consuming and physical for roofers of all experience levels. Of the many types of handheld thermal cameras, we recommend ruggedized devices that can handle the potential moisture and dust intrusion, as well as any drops onto hard surfaces. Additionally, contractors should use a thermal camera with radiometric capabilities that will allow them to capture the temperature of every pixel in the scene, which will better enable the operator to pinpoint specific problem areas for further inspection or repair.

Now, many roof inspectors are utilizing unmanned aerial drones equipped with both thermal and visual cameras, as they can easily fly over large areas and provide a thorough view of an entire roof in just a few minutes, which is especially useful for hard-to-reach or dangerous areas. Inspectors may still have to go onto the roof and use traditional test methods to further assess the problem, but the overall time compared to doing a handheld thermal inspection alone is greatly reduced, and potentially much safer as the drone pilot can keep their feet safely on the ground.

RT: What kind of training or regulations are required for operation of these devices?

JA: Laws and regulations defining who can make roof damage recommendations vary from state to state. Thus, if using a drone equipped with a thermal camera, operators should familiarize themselves with local requirements and always work with a licensed professional to ensure the scans hold real, actionable value. Additionally, there’s a national standard defining the methodology thermographers using handheld cameras to inspect roofs should be using. The standard, ASTM c1153-10 (2015) Standard Practice of Location of Wet Insulation in Roofing Systems Using Infrared Imaging, applies to drone operators as well.

FLIR also partners with the Infrared Training Center (ITC) to provide certification courses that teach best practices and techniques. It’s important that roofers understand the way the camera “sees” different roof materials, and learn techniques for knowing when, for example, a “cool” spot in the scene is just cool air, or water under the roof membrane. It is important to know how each layer in the roof system affects thermal patterns. The user must understand the assembly of the roof so they can understand if what they are seeing is an issue or just part of the structure.

Planning for Use

RT: What is the life span of a typical device if used and cared for properly?

JA: There are multiple factors that play into the life span of a thermal camera. For roofing applications, it’s necessary to have a ruggedized camera that can handle the environmental factors present on a roof, such high heat or bitter cold, as well as handle drops onto hard surfaces or from one floor level to the next.

Many thermal cameras come equipped with a rechargeable lithium-ion battery. Therefore, camera operators must take care to ensure the device and its batteries remain away from high heat (such as on the dashboard of a truck in the middle or summer), or left out in freezing temperatures—all factors that can significantly impact the performance of the battery and thus the life of the camera. A device for roof inspections, if cared for properly, can last many years.

RT: What software is required and how can contractors access the information gathered by the camera?

JA: Software is not required to use a device, but is a recommended add-on for editing images and creating comprehensive inspection reports. Users have various options for software—there are free versions available that provide basic image editing and quick reporting, then there are paid versions that offer advanced measurement and image analysis, as well as editing and customized reporting.

Depending on the software, operators can adjust the colors, apply spot meters, isolate certain locations within a scene for further inspection, or manipulate an image in post-processing to better interpret a scene to be included in a post-inspection report. For large-scale roof inspections, FLIR offers a paid software option that allows customers to batch edit a large number of images, saving a lot of time.

Key Criteria to Consider

RT: What variables on the forward-looking infrared devices themselves should contractors be aware of?

JA: For roofing applications, there’s a national standard defining the methodology thermographers using handheld cameras to inspect roofs should be using (the aforementioned ASTM c1153-10 (2015)).

Within the device itself, there are a few good rules of thumb for roofers to consider when considering a handheld thermal camera. These include:

• A radiometric thermal camera, meaning the camera can detect and measure the temperature of every pixel in the respective camera’s field of view

• One that has an IP65 rating or higher—a camera that is dust-proof and able to perform in the rain or snow

• A camera that allows one to take and record both photos and video, for post-processing or review after the inspection, as well as one that offers additional software features like multiple spot temperature meters, including the ability to adjust the temperature gain within specific ranges

• One that includes an ergonomic gun trigger that makes a camera easy to operate with one hand, versus a touch-screen device that often requires two hands to operate. At times, these can be difficult or impossible to use while wearing heavy gloves.

About FLIR Systems

FLIR Systems was established in Tigard, Oregon, in 1978 to pioneer the development of high-performance, low-cost infrared (thermal) imaging systems. However, the history of the company goes back even farther, to the 1950s, when Agema of Sweden (later purchased by FLIR in 1998) developed the first commercial thermal cameras, primarily for inspecting power infrastructure. Those first thermal cameras were so large and heavy, they were mounted onto the back of a car or truck.

Today, FLIR offers a diversified portfolio that serves a number of applications in government and defense, industrial, and commercial markets. Thanks to major advancements in the size, weight, power, and cost of thermal imaging cameras, FLIR thermal cameras can be found in cellphones all the way to large gimbals on military or search and rescue aircraft. For more information, visit www.flir.com.