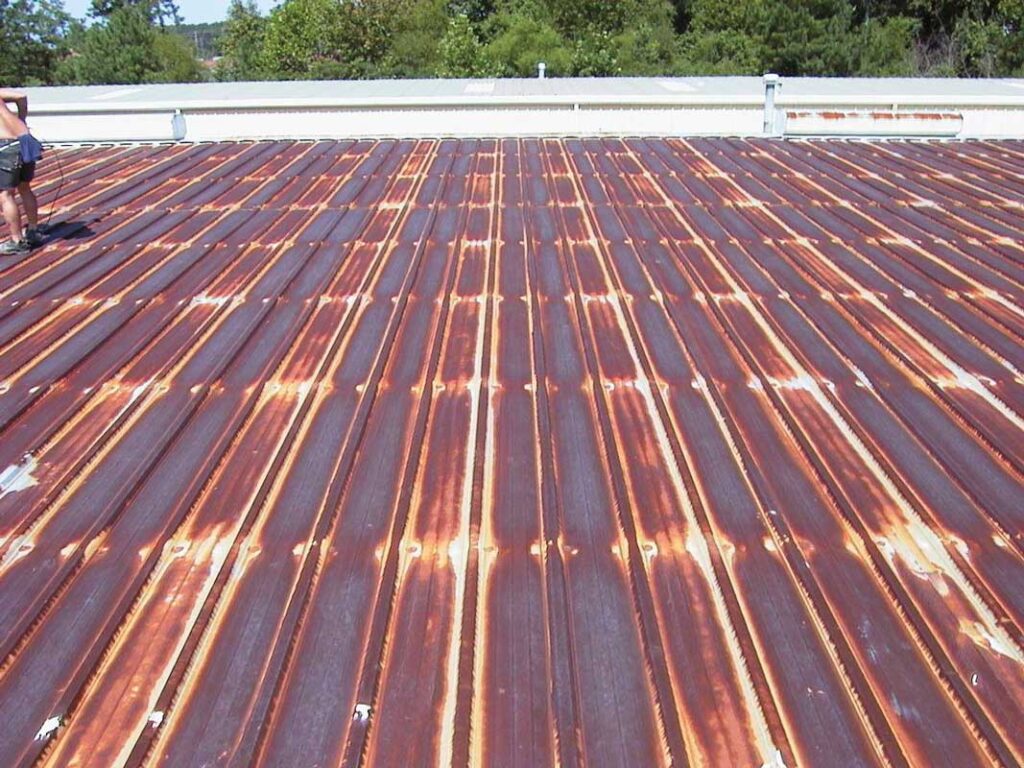

A customer called looking for a one-coat system for their metal roof. They were concerned that other manufacturers required a primer over the roof due to the rust, and one suggested a double coat of their topcoat, making it cost-prohibitive for them.

They were relieved when we told them our solvent-based system would work and that it only needed one coat without any need for a primer. The customer tested a thousand-square-foot section and watched for six months. Later, the customer ordered 900 gallons to finish the roof and used an airless sprayer for the application. The airless spray pump required a minimum 3,300 psi output pressure rating and adequate delivery volume to support the spray tip orifice at 1.1 gallons per minute (gpm).

The customer later called back, informing us that it was the first time in a year that water had not penetrated anywhere in the building. In addition, a 20% section had an acrylic product, and they were concerned they needed to powerwash that off before applying the BUTYL Liquid Rubber. There was no need to do that either due to the cross-linking properties of the solvent. The customer saved on both material costs and labor hours as well.

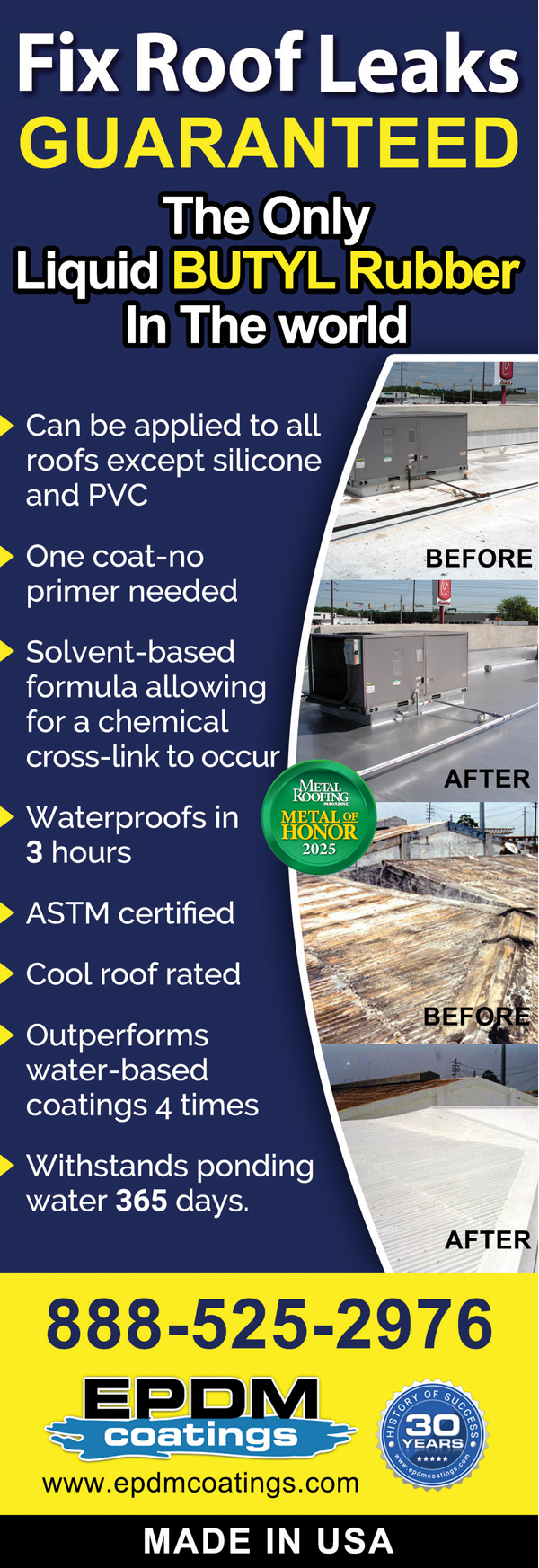

Metal roof before. Photos courtesy of EPDM Coatings

Warehouse metal roof after it was coated with Liquid BUTYL Rubber.

Case Study Details:

Contributed By:

EPDM Coatings. www.epdmcoatings.com

Roof Location:

Shelton, Connecticut

Installer:

Building Owner

Roof Size:

45,000 sq. ft.

Roof Pitch:

2:12

Coating:

Liquid BUTYL Rubber from EPDM Coatings