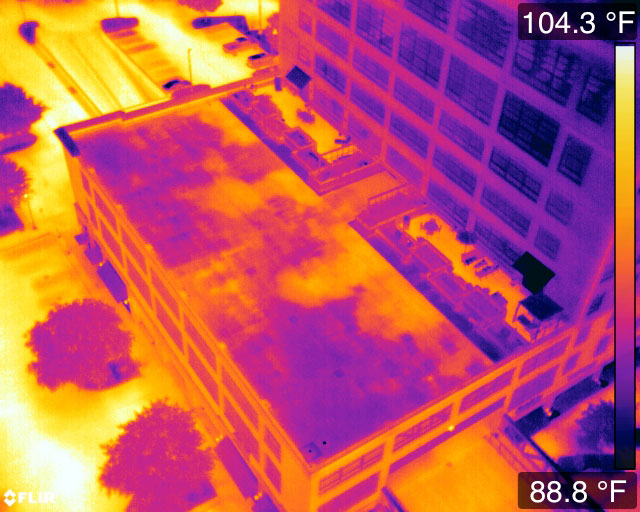

Thermography, also known as infrared (IR) imaging, can be a valuable tool for roofers. It can be used to assess the condition of roofs, diagnose problems, and aid in finding appropriate solutions for the property owners.

However, since it requires specialized equipment and knowledge, it leads to the question: Should it be done by a thermographer (hired out), or can roofing company personnel do it themselves?

Jeff Carrillo, certified thermographer and owner of building enclosure consultant Structura View, which specializes in performing moisture surveys on commercial low-sloped roof systems, says there are circumstances in which each would be an appropriate course of action.

When To DIY

Roofing companies can either buy or rent the equipment needed to perform the IR scans. “The cost depends on the quality that you want to get,” Carrillo explains. The highest resolution you’d need for handheld rooftop testing is 640 x 512. Lower resolution is available, but he doesn’t recommend anything less than 320 x 240 resolution for handheld, on-roof testing. “You can get lower resolution, but, in my opinion, you really start to sacrifice quality and feasibility of studying the roof system very well.”

If looking to perform drone-based imaging, he recommends not less than 640 x 512 resolution since the camera is further away from the area to be scanned. “It’s essentially the same concept. You can rent or buy. But I typically don’t recommend a resolution lower than 640 x 512 because it will be a big blurry mess.”

Carrillo said he can think of three main reasons for a roofing company to do their own thermography.

The first is if a roofing contractor is hired to fix a leak that proves to be difficult to repair. When there is a leak, “The roofer always gets the blame,” Carrillo says. The problem could actually be moisture in the walls – not the roof – so it would be to the roofer’s benefit to use thermal imagery to help identify the source of the leak, even if it proves to not be roof related.

The second situation is if the roofer offers routine inspections in correlation with routine maintenance programs. An annual thermal scan can act as an additional quality control check to help spot leaks before they are experienced in the building, preventing more extensive damage.

The third is if a roofing contractor has a lead for a roof, but isn’t sure if they should recommend repairs, remediation (roof recover or coating, for example) or full replacement, thermal imaging can aid in assessing the overall condition of the roof. Providing a property owner or manager with data that backs up your recommendations carries a lot of weight in the sales process.

When To Hire It Out

Three situations that warrant hiring a thermography consultant immediately come to mind.

The first is any time insurance claims are involved. A roofing contractor can present a conflict of interest if they do the thermography evaluation themselves when an insurance claim is involved.

The second is any time there’s a necessity for an unbiased report. If the roofer is trying to sell a new roof that will be paid by an insurance company, the roofer’s condition report may be seen as biased.

The third is any situation in which the report needs to be certified (i.e. stamped by a licensed thermographer). And if the roofer doesn’t have a thermographer certification, the report can be discredited.

Additionally, regulatory agencies like Broward County and Dade County in South Florida require moisture surveys to show that less than 25% of the roof contains moisture to qualify for a re-cover or coating, explains Carrillo. To determine the moisture content in these cases, it requires a certified third-party professional.

The Value of IR Imaging

Many times roofers bring Structura View in to help with thermal and moisture scans on roofs that they’re trying to sell. “The roofer wants to show clients the condition of their roof in an unbiased way, rather than the contractor coming in and saying ‘This is what we think is going on.’” If the contractor puts in an estimate that doesn’t include any cost to replace materials because of moisture in the system, if they find moisture, then they must put in a change order. “Then they have to go back to the building owner and say, ‘You have to pay more because we found wet insulation.’ If the thermographer comes in from the beginning, the contractor can tell the client, ‘Based on the moisture survey, this is what the whole remediation will cost.’ There won’t be any major change orders unless there’s a delay and the situation changes.”

Carrillo believes thermography is a helpful tool in landing more commercial work. “Any time you can give a commercial building owner an estimate based on actual conditions rather than speculation can help you land the job.” Additionally, disclosing all the details at the front makes the roofing contractor look a lot better than having change orders and added costs at the end. MR