Metal of Honor awards: 4

Website: www.ascmt.com

PHONE: 509-534-6600

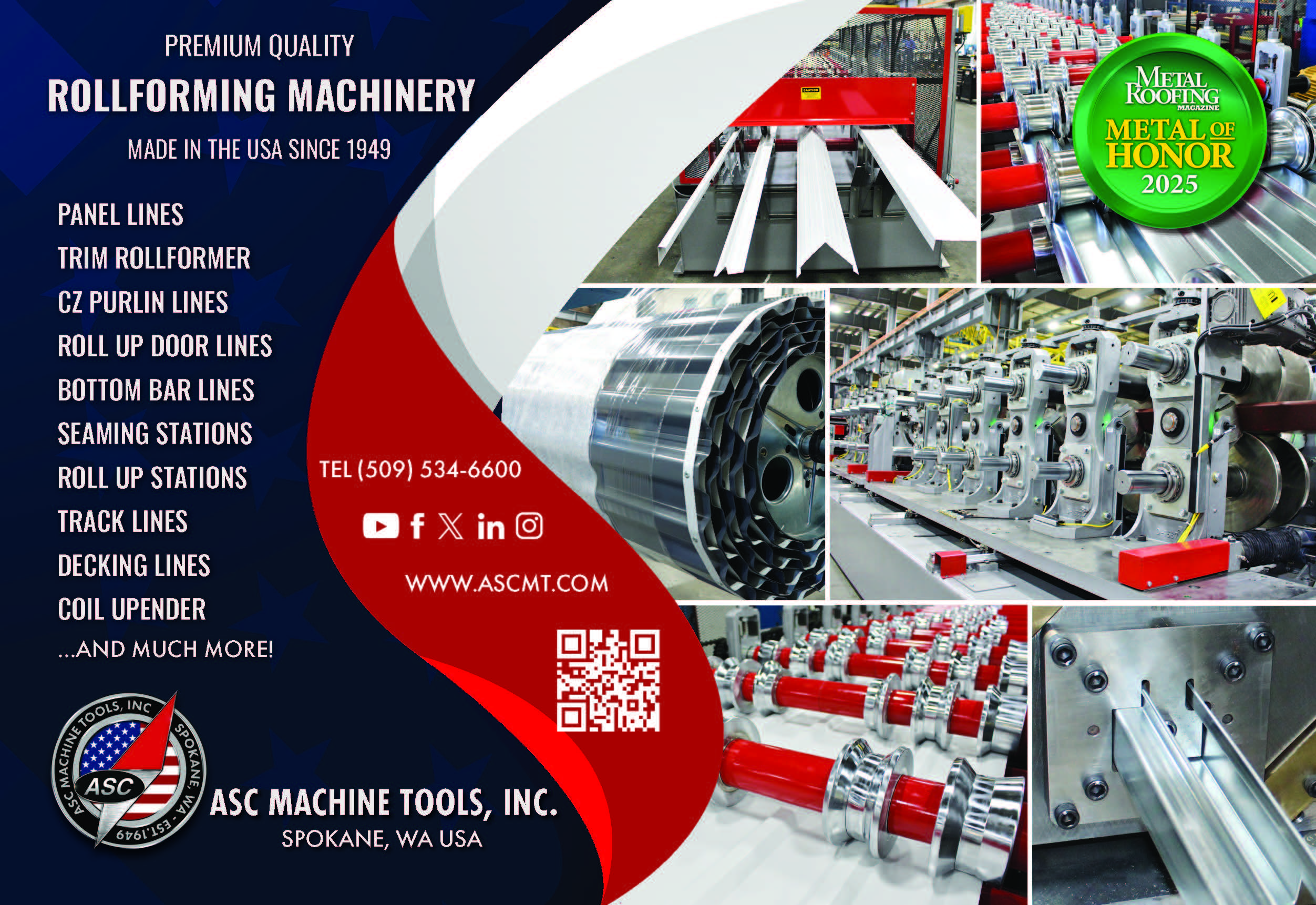

ROLLFORMING ROLL UP DOOR COMPONENTS

A Roll-Up Door System consists of three main components that can be roll-formed: The panel curtain, the bottom bar, and the guide track.

1. Panel Curtain: The panel for the door curtain is formed using a post-cut rollforming line, ensuring that flare is eliminated, which is crucial for the seaming process. The rollformer features a Cee-Frame punching station that adds holes for the door lock just prior to the Post-Cut Shear. These lines can produce roll-up doors for mini storage facilities and larger doors for garages, warehouses, and commercial buildings.

2. Bottom Bar: The bottom bar line includes a Decoiler and a Feeder/Straightener tower, which feeds material into a 3- to 4-station punching unit. All holes in the bottom bar are pre-punched while the material is flat. From the punching unit the material is fed into the rollformer. During the rollforming process, the astragal is introduced into the bottom bar profile. A flying cut-off shear cuts it to the correct length.

3. Track Rollforming Line: The track rollforming line setup is similar to the bottom bar line. The modular punching unit punches all required holes and a notch at the top of the track. The bottom bar line also features a flying shear at the end that cuts the track to the correct length. These Lines can produce either Mini Storage Door Track or Commercial Door Track.

Roll formed panels and bottom bars are seamed together and rolled up on an offline Seaming Station and Roll Up Station

ASC Machine Tools, Inc. is a recognized leader in the design and manufacturing of Roll-Up Door Equipment. Since 1949, all of our equipment has been proudly made in Spokane, WA, USA.