By Metal Roofing Staff

Soffit functions include ventilation, protecting the underside of the roof overhang from the elements, and guarding the structure from pests and birds that might try to enter through gaps. To serve these functions, soffits need to be installed properly. It’s impossible to summarize the “right way” to install them, as locations and situations vary greatly, but here are tips that apply in nearly every situation.

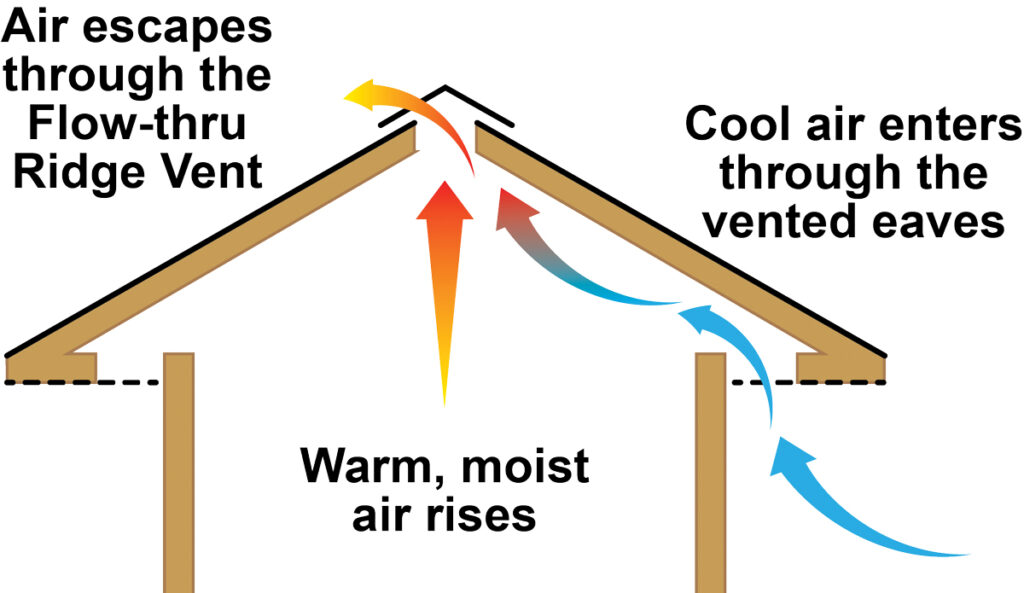

Ventilation

Function is as important—if not more important—than aesthetics. Soffits need to function, and vented soffits are all about airflow. For a ventilation system to function properly, air intake and exhaust must be equal. Without equal or slightly greater inlet area, a ridge vent won’t function properly. In some cases, a lack of intake can lead to a vacuum in the ridge vent as air is pulled in, potentially causing water and/or snow damage. (Don’t fall victim to the misconception that “more is better”; match the ventilation system to the building’s needs.)

Precut Panels

One of the easiest ways to speed up the soffit installation phase is to use precut soffit panels. Ask your metal supplier if they offer precut panels; using precut panels saves a lot of man-hours.

The Right Tools

Quality tools make the job easier; don’t skimp on quality. It’s important to use the right tools to achieve clean, precise cuts. Using the wrong cutting tools and techniques can damage the soffit panels and lead to rough edges or an uneven fit.

Vented soffit. Air inlet volume should match air exhaust volume. courtesy of MWI Components.

If cutting panels on the jobsite, pay attention to the measurements: Make sure the size isn’t changing on the fascia. Failing to get an accurate measurement can lead to incorrect sizing of soffit materials, causing gaps, overlaps, or an uneven appearance. It’s as important to use accurate measuring tools as it is to use accurate cutting tools. Double-check all measurements before cutting material to prevent unnecessary waste.

The most common tools used in soffit installation are hand snips, a level to keep panels straight and aligned, and a cutting table for multiple sized pieces. Blades typically have fine, carbide-tipped teeth that can handle the hardness of metal without dulling quickly. Use the correct blade: a “ferrous metal” blade for cutting steel or a “non-ferrous metal” blade for cutting aluminum. Cut panels from the back to protect the painted surface.

If working in a confined space, a jigsaw fitted with a fine metal cutting blade can be used (the blade should have at least 24 teeth per inch to ensure a smooth cut). Snips that deform the waste material will make it clear which pieces should be used and which should be discarded. Additionally, offset snips keep your hands away from the metal, making it less likely to cut yourself.

In a pinch, an angle grinder fitted with a thin cut-off wheel designed for metal can also be used for cutting soffit panels. No matter the tool, use a steady hand and consistent pressure to prevent burrs or rough edges.

Installation

The most common problems metal roofers encounter when installing soffits include difficulty maintaining level with the wall’s Z-profile, ensuring the fascia remains level during soffit installation, and dealing with fascia that isn’t level or protrudes inconsistently from the building. Misaligned panels can create an uneven and unprofessional appearance. Careful alignment and periodic visual checks throughout the installation process are essential. Ensure each soffit panel is seated properly before moving on to the next and don’t over-tighten.

To prevent these issues, ensure the surface to which the soffit is attached is sound, clean, dry, and free from obstructions. Improper surface preparation can lead to issues later on.

Also, failing to provide sufficient support for the soffit panels can cause sagging or detachment over time. Refer to the manufacturer’s instructions to determine the proper support brackets or channels required. Use fasteners according to the manufacturer’s guidelines and, if necessary, apply flexible sealants to maintain a weather-tight seal while allowing for thermal movement.

Safety

Wearing protective, cut-resistant gloves that fit well and provide good grip, in addition to safety glasses, can prevent unnecessary injuries and downtime, ultimately making the installation process easier.

In conclusion, a successful soffit installation hinges on proper ventilation, precise panel cutting, the use of quality tools, meticulous installation techniques, and strict adherence to safety protocols. By following these guidelines, you can ensure a trouble-free installation that enhances both the functionality and aesthetic appeal of any structure, while also prolonging the lifespan of the soffit system. Remember, attention to detail from start to finish will yield the best results and minimize potential issues down the road. MR