The ability of a hydrokinetic standing seam metal roof system to effectively manage rainwater with downslope obstructions, is absolutely vital to the system’s integrity and watertightness.

HVAC units, roof curbs and other rooftop modules “even when installed correctly and per manufacturer’s instructions” will impede rainwater flow and, in some cases, will allow for water to collect or back-up during active rain events, potentially compromising flashing joints, roof panel end terminations and most importantly the side-seams on hydrokinetic (i.e. snap lock and batten cap) systems. This rainwater collection (back-up area) is increased the further downslope the unit or obstruction resides.

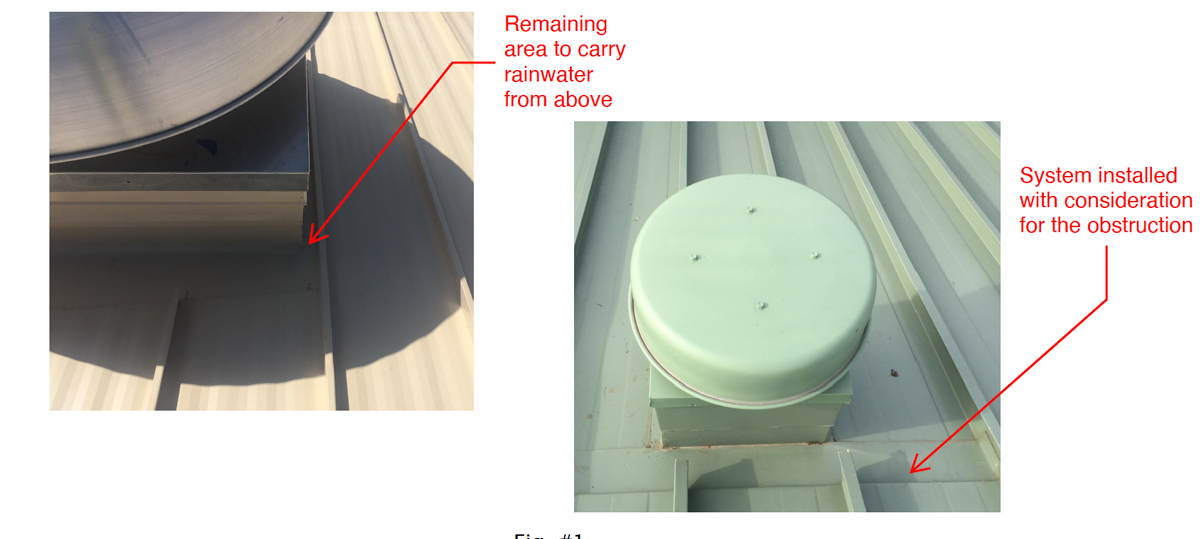

Consider a 5’ wide roof curb installed on a system with 16” wide panels. Assuming the unit is centered over the panels, this will leave only 2” on each side of the unit to carry all the upslope rainwater (see Fig. #1). Essentially, the curb obstruction is causing the rainwater to be funneled down to an area almost 90% smaller than originally intended. If the unit is installed significantly upslope (next to the ridge) the concern will be minimized, as the amount of rainwater to be channeled around the obstruction is reduced.

Conversely, if the unit is 10’ to 20’ or even 30’+ downslope, the concern obviously becomes greater due to the increased amount of rainwater to be handled, or in this case funneled. It’s like trying to connect a garden hose to a fire truck with the pump running, the surroundings and in this case the roofing components, quickly become overwhelmed and effectively submerged.

The first item to take under consideration is “unit/curb placement and location.” The curb placement itself has the greatest bearing when considering the rainwater handling capabilities of the standing seam metal roof (SSMR) panels. As stated in the preamble, obstructions located close to the uppermost area of the roof present the least concern. However, curbs located further downslope present issues that must be addressed to assure the roof system’s intended performance. For the purpose of this paper, we will assume that the units, curbs, etc., to be discussed are a minimum of 20’ downslope from the ridge or high eave.

One should think of an SSMR panel to be much like a rain gutter. Just like a gutter, the SSMR panel is a channel or trough that carries rainwater. Just like a rainwater gutter, its particular size (height and width) determine the amount of water it can successfully carry without overflowing. When obstructions are introduced to a SSMR system, the roof panel’s width often may be effectively reduced to the point it will overflow and allow for rainwater to penetrate into the side-seam of the roof panel.

To accurately determine the volume of rainwater a roof panel can carry, we must apply the same rainwater management calculations utilized for typical gutter and downspout systems. Albeit we can determine the rainwater volume via this method we remain limited as to managing such a condition. This is to say, that the roof panel cannot be modified to receive more rainwater without significant and aesthetically unpleasing modifications.

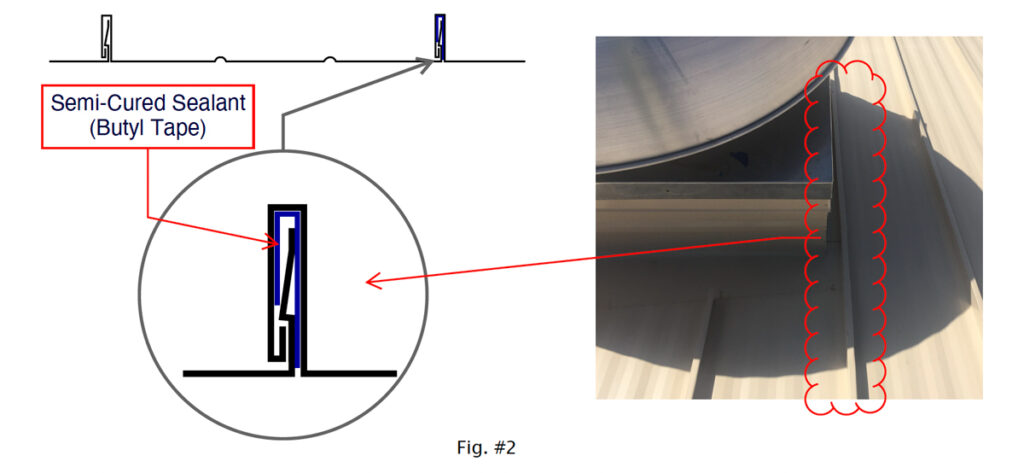

Alternatively, perhaps the easiest solution is to anticipate submerged side-seams and modify the panel installation to successfully manage such an occurrence. This can be accomplished via double-locking of the side-seams on mechanically locked systems and by installing a semi-cured gasket material within the side-seams during the installation on snap-lock systems (see Fig. #2). Regardless of the kinetic abilities of the roof system, this modification is intended to create more of a hydrostatic seam configuration specifically where the restricted rainwater flow location exist and adjacent areas.

Additionally, designers should take under consideration of the physical restrictions along with the proximity of the adjacent roof panel side-seam(s) created via the roof curb, unit, etc. As seen above, crimping of the highlighted roof panel side-seam is physically impossible via hand or automatic crimping devices. Thus, field modifications of the seam configuration must be accomplished in order to achieve a watertight seal. In situations such as this, the necessary modifications noted above may be applied but are sometimes limited and the application of a field applied sealant and/or caulk must be considered. Understandably, surface applied sealants become weakened over time and will require periodic maintenance yet given the anticipated rainwater flow in areas such as this, these alternative solutions are certainly worthy of consideration.

As roofing professionals, we should be aware that all roof-top obstructions restrict rainwater flow in some way or another and we must be prepared to make the necessary modifications, when needed. MR

Kent Childers, President of EnSpec LLC, Hiddenite, North Carolina, is an IIBEC member, consultant and frequent installation trainer and speaker with over 30 years metal and low-slope roofing experience.