OK guys, let’s get something straight right out of the box. As a general rule, satellite imagery is not a high enough resolution for accurate material takeoffs. Hmm, that’s a big statement since everyone wants to use “satellite imagery” for estimating. The issue is, you cannot improve the resolution of an image, just like you cannot remove a tree that overhangs and covers half the roof, making it impossible to extract a useful dimension. This limitation is a function of the resolution or image quality, and satellite images are generally not as high resolution as aerial images from specialized survey aircraft. If you rely on satellite imagery, these issues cannot be overcome; instead you must use the information provided and do the best job you can with it when creating roofing quotes. Sometimes, you will have to drive out and do a site measure.

Most services that use imagery for estimating will typically use aerial imagery taken by aircraft at relatively low altitude (compared with satellites). This provides more precise imagery that can be used to do an initial takeoff and from which a client proposal can be prepared. But, depending on your roofing material, you will always have the clause “Subject to confirmation by site inspection” boldly printed on the quotation. You must keep in mind that an estimate is not a material takeoff—ask any quantity surveyor who takes pride in their profession.

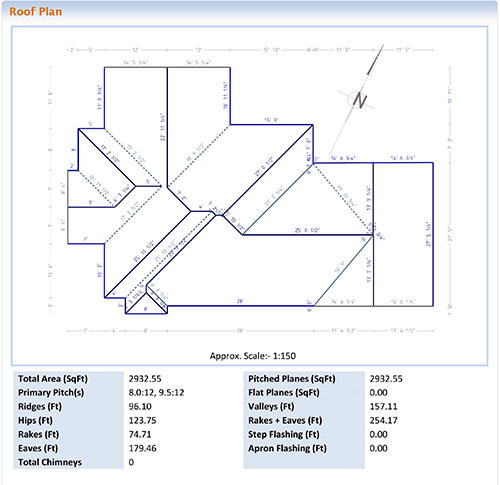

Not all roofing jobs can take advantage of the use of aerial images. Most obvious of course is new construction, so if the bulk of your work is new construction, then you will be working from architects’ plans (usually a PDF document sent to you via email or downloaded from a file sharing site). In this case, you need a program that allows you to use the PDF as a guide to re-create the roof geometry so that a detailed material takeoff can be extracted. A 3D CAD-based software is the best solution, as it has the built-in tools needed to ensure accuracy and repeatability using imagery, PDFs, or field measurements.

If you are using smaller format roofing products such as shingles, tiles, or slate, then a takeoff from an aerial image will usually work OK. This is generally enabled by the fact that unused material can be sent back to your supplier for a credit against the next job. Bear in mind that if your quote includes a lot of material that is subsequently not used, then you run the risk of overpricing and missing jobs because you are too expensive. Instead, it is better to use tools that allow you to generate a quotation for the job that is reliable and exactly right each and every time. Good software assists in this objective.

Use Aerial Images to Get a Foot In the Door

If a lot of your work is metal roofing or you plan to get into metal roofing installation, then the only place for quotations generated from aerial images (satellite or aircraft) is to get your foot in the door. Your quotation will always be “Subject to confirmation by site inspection.” In my experience, there are no aerial images accurate enough to extract an accurate cutting list for a metal roof.

Having said this, quotation software is still an extremely valuable tool, especially if you want to get a bunch of quotations out there—the more quotations done, the more chance you have of winning new work. However, this is not productive if you have to spend hours at a time doing site visits to measure each job. You must be trying to bang out as many quotations as you can, “Subject to confirmation by site inspection.” Then, when the job is confirmed and the deposit paid, visit the site to confirm the exact requirements.

With the right software tools, I know it is possible to knock out 10 to 15 residential roofing quotes a day using aerial images.

There is a caveat on these comments for metal roofing guys: It depends on how you work. Some contractors order their metal roof panels from a manufacturer who fabricates them off-site. In this instance, the cutting list has to be perfect and with the right software, this can be achieved. Other roofers have portable roll formers and fabricate the panels on the job site, which simplifies the quoting process. As long as you order enough coil, you don’t have to be so precise with your takeoff—just order the correct amount of coil. Once again, good software tools assist with this and ensure that you do not have excessive waste.

Turn to Software for Panel Layout and Itemizing

For metal roofers, not only do you need accurate information so you win the job, you need accurate information so you have the right materials on the job site (not just the panels, but the clips, screws, sealants, underlayment, etc.). This will make the job easier to install, result in minimum waste, and help you achieve a nice profit. Software can help roofers achieve all of these objectives by creating the most accurate panel layout on a 3D model of the roof, optimizing the reuse of offcuts (if appropriate), and itemizing every single nut, bolt, and screw—all from the 3D model. It will even account for the overhang into the gutter. This is one important aspect you gain from the use of such software—a detailed quotation is not just panels, it is everything else that goes into a job: fasteners, clips, ridges, hips, valleys, gutters, drip edges, downspouts, sealant, insulation, underlayment, penetrations, boots, flashing, maybe even solar panels… This specialized software does a complete job based on how each item of inventory is supplied and utilized. If you need 112 special clips, you get 112 special clips.

By now someone will be yelling, “What about drones?” Well, they are just another source of aerial images from an “aircraft.” However, take care—drones have their own issues if you wish to use them to assist in quoting. First and most obvious is the fact that you are now back to doing a site visit and with setup, etc., you may only get a couple of jobs done a day. The real issue with drone images is more insidious—something that sneaks up on you if you do not pay attention—parallax error. To fit the whole property into the shot and not fly so high that the FAA comes visiting, the cameras on most drones have a very wide-angle lens. This lens can turn a square-shaped roof into a “cushion pad” shape. If you do not get sufficient altitude to take the picture of your roof, the edges are not square and this compromises the measurements that re-create the roof model that you will use to extract your material list and quotation.

To be clear, if you quote jobs by sticking your thumb in the air and quoting “X” dollars per square, labor, and materials, then none of what I am saying here matters. If you are seeking fair, accurate, reliable, and repeatable quotations that enhance the reputation of your business, you need the best software tools and appreciate the shortcomings of each process you employ to generate said quotation.

If you have any questions at all, drop me a line: [email protected].