With each piece of equipment, we supply a detailed manual with clear instructions and tips on safety, operation, maintenance, troubleshooting, and more. The manual also contains a schedule of daily, weekly, monthly, and yearly maintenance routines. Unfortunately, not all customers follow the recommended schedules, which can result in equipment failure, repairs, and downtime. Two of the most important maintenance routines:

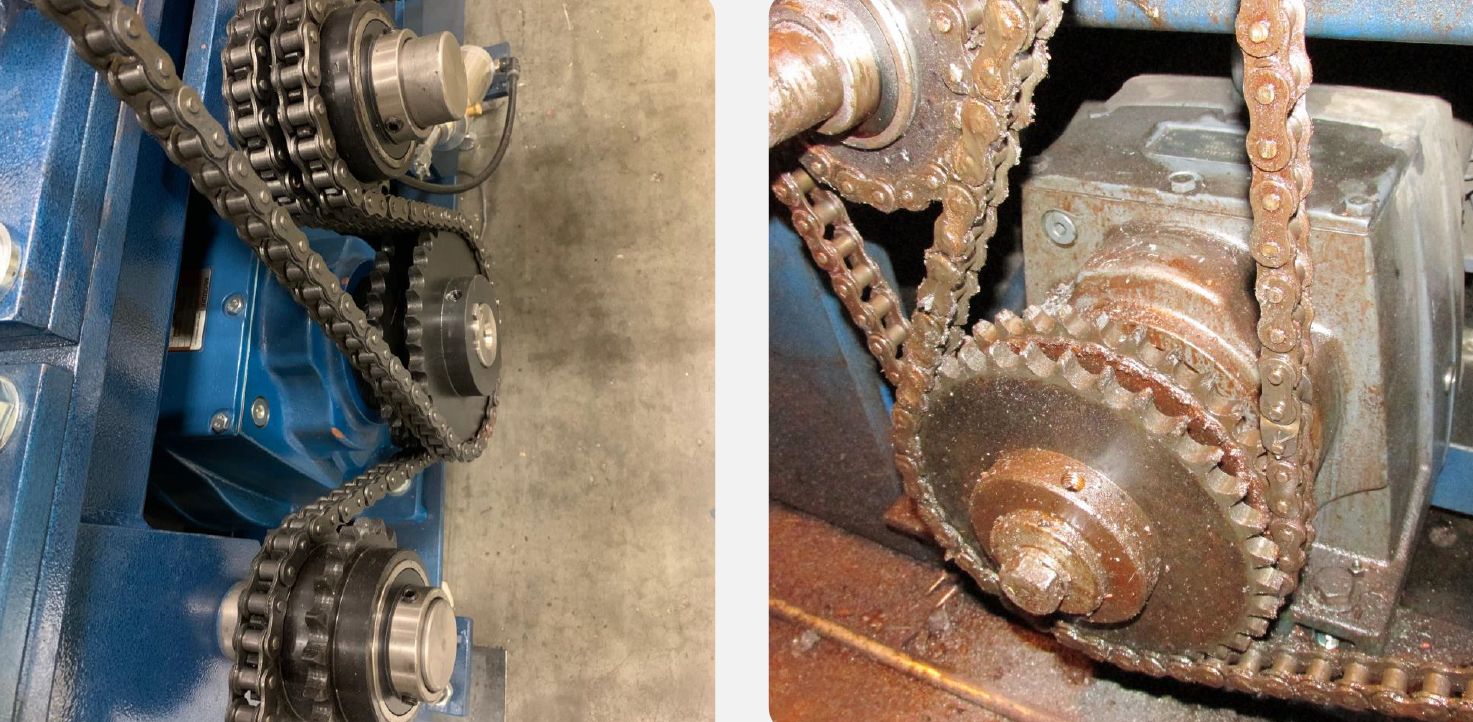

• Keep all power transmission products lubricated. This includes bearings, bushings, sprockets, chains, and gears. This particularly pertains to those customers running high volume production.

• Keep up on intervals for your hydraulic power unit maintenance. This includes the change of the return line filters and the hydraulic oil.

And please, read the manual to prevent serious injury!

• Only individuals who have read the manual thoroughly and comply with all the recommended safety guidelines are qualified to use, maintain, and operate the equipment. Please THINK FIRST, ACT SECOND!

There are more than a handful of maintenance tasks that need to be routinely done, but a few general ones for roll formers are:

• Inspect the roll tooling gaps or clearances to make sure they are set properly for the material being ran. This needs to be done daily or whenever the gauge is changed. This can be done with a set of feeler gauges or an inspection mirror. It also serves two purposes: it will help prevent damage to the roll tooling and will help you run a quality product.

• The next one is lubrication. This covers several areas on the roll former like the tooling (if lubrication is required), the bearings, gears, and chains. If this task falls behind, it can cause premature wear on parts, ending in a breakdown of the machine. The intervals for this task can vary greatly, so it is best practice to follow the OEM recommendations for the lubrication schedule on the roll former. The ultimate goal of preventative maintenance is to prevent costly breakdowns of machinery and reduce unscheduled downtime.

When it comes to safety, it should be a conscientious priority for everyone to follow their company’s guidelines when operating or performing maintenance on a roll former. A few tips that will help keep everyone safe are:

• Keep it clean and organized. This includes the roll former and the work area around the machine. A machine that is well kept is a lot easier to operate safely and to maintain. It makes it easier to detect problems like a hydraulic leak or a seal going out. This should be a daily or weekly routine (depending on the production schedule) and will promote safety.

• Keep the machine guarding and barriers in place. These were designed to keep you safe and avoid injury. We have been to too many places where the guarding has been removed or bypassed to do repair work or to make adjustments to the roll former and then these protective devices were just simply left off. Keep the guards in place and you get to keep your fingers and hands to go home with!

• Proper PPE should always be worn when operating or working near a roll former. Gloves, protective eyewear, and steel-toe boots are a must.

• Never operate a machine without safety cages and other safety features enabled. The machine should also be well-maintained and a visual inspection done before each use with more in-depth maintenance performed weekly, monthly, or yearly depending on the manufacturer of your machine. See your operator’s manual for these schedules.

This is a perfect segue for maintenance. Before performing any maintenance on your machine, activate your emergency stop button(s) and turn off the power. This will prevent electrical shock as well as prevent the machine from being turned on. Once the machine is off, here are two key maintenance tasks:

• Inspect and lubricate all chains or worm-drives weekly (or as recommended by your machine manufacturer). Failure to do so will make a failure more likely to occur and cause your machine to be down.

• Wipe down and clean tooling weekly (or as recommended), especially when running galvanized panels. If your rollers become dirty or damaged, it will show in your finished product. Regularly cleaning the rollers will prevent small imperfections from becoming major problems.

Our top two maintenance tips involve relying on one’s senses:

• Visual: Taking five minutes at the beginning of every shift to make a visual sweep of the die gapping is a quick way of catching a costly mistake before it happens. You will need a simple inspection mirror and a white piece of paper. Hold the mirror so you can see the gap in the top and bottom dies, and hold the paper on the opposite side to illuminate the gap. Move across each pass, making sure the gap is consistent. If something has come out of adjustment, you may notice an inconsistent or closed gap.

• Hearing: Roll formers are not the quietest pieces of equipment, but if you hear something that stands out to you, stop the machine and check it out. Squeaking might be a bearing going out, or a grinding sound or vibration could mean sprockets or gears having abnormal wear. These could be easy fixes unless you let them go for too long.

Important safety considerations for operating a roll former:

• Get to know the E-stop. Knowing the location of the emergency stop buttons on a roll former is sometimes taken for granted. Mentally preparing yourself to hit that E-stop is key to avoiding disaster. We’ve seen this happen and have been guilty of it ourselves, but when material crashes or something unexpected goes wrong, it’s easy to be surprised and move toward the commotion. The only control you have is getting to that big red button as quickly as you can.

• If working around roll forming equipment is your livelihood, take care and mind the necessities. Safety glasses, gloves, and hearing protection should be a daily priority.

• Lubricate your tooling. Operators should keep a thin film of lubricant on the tooling. All high-quality roll forming dies are chrome-plated to reduce friction coefficient and increase tooling life, but adding a small amount of lubrication will help overcome the surface speed difference inherent in the tooling and increase tool life and reduce the possibility of scrubbing or scratching the paint.

• Change the hydraulic oil. Hydraulics are sensitive to contaminants. Dust can enter through the breather in a shop environment and moisture can enter through condensation and temperature changes. Regular maintenance can significantly increase the life of your hydraulic system and components.

• Always do a walk-around before starting a machine. Verify that all guards and safety switches are in their proper place and condition.

• All operators should be familiar with proper lock out and tag out procedures for working on equipment.

• For our “Field Machines” that are hydraulically powered, changing out the hydraulic fluid at least twice a year is very helpful from a power standpoint. Like any piece of machinery, whether it be a car, a truck, a backhoe, or a standing seam machine, clean oil goes a long way.

• Keep the drive roller chain lubricated with chain lubricant spray, not grease!

• First and foremost, always power off the machine while working on it. If it needs to be turned on, then two people must be involved.

• Never bypass the emergency stop buttons!