Before purchasing a portable roll former, many contractors want to know the return on investment (ROI). This article dives into what factors to consider and how to calculate ROI.

Year after year, metal roofing and siding continues its upward trend for its energy efficiency, sustainability, and durability against severe weather and wildfires, along with strong aesthetic appeal. Meanwhile, new technologies—like innovative coil coatings, treatments, and more color and design options—continue to emerge industry-wide.

In any business, as operating and material costs increase, the profit margin thins. With recent increases in tariffs on steel and aluminum, metal roofing contractors are wondering what to expect in rising material costs this year. While it’s hard to predict, one thing seems certain—they’re slated to increase.

As a contractor you can continue to raise prices by following market changes, but any metal roofing operation must also remain competitive. If you’re purchasing factory panels from a national or regional manufacturer, you’re competing with contractors forming their own panels at a lesser cost.

In recent years, the opportunity to increase profits has driven contractors and panel manufacturers to invest in portable metal roof and wall panel machines. If you haven’t, 2025 may be the year to purchase your own. But is the hefty price tag worth it? How do you calculate its return on investment (ROI)?

Below, we’ll break down the major factors—material costs, labor expenses, square footage of the job, and the type of standing seam metal roof—to give you a clearer picture of how a portable roll former can positively impact your bottom line.

Material Costs: Savings & Control

Buying Coil vs. Manufactured Panels

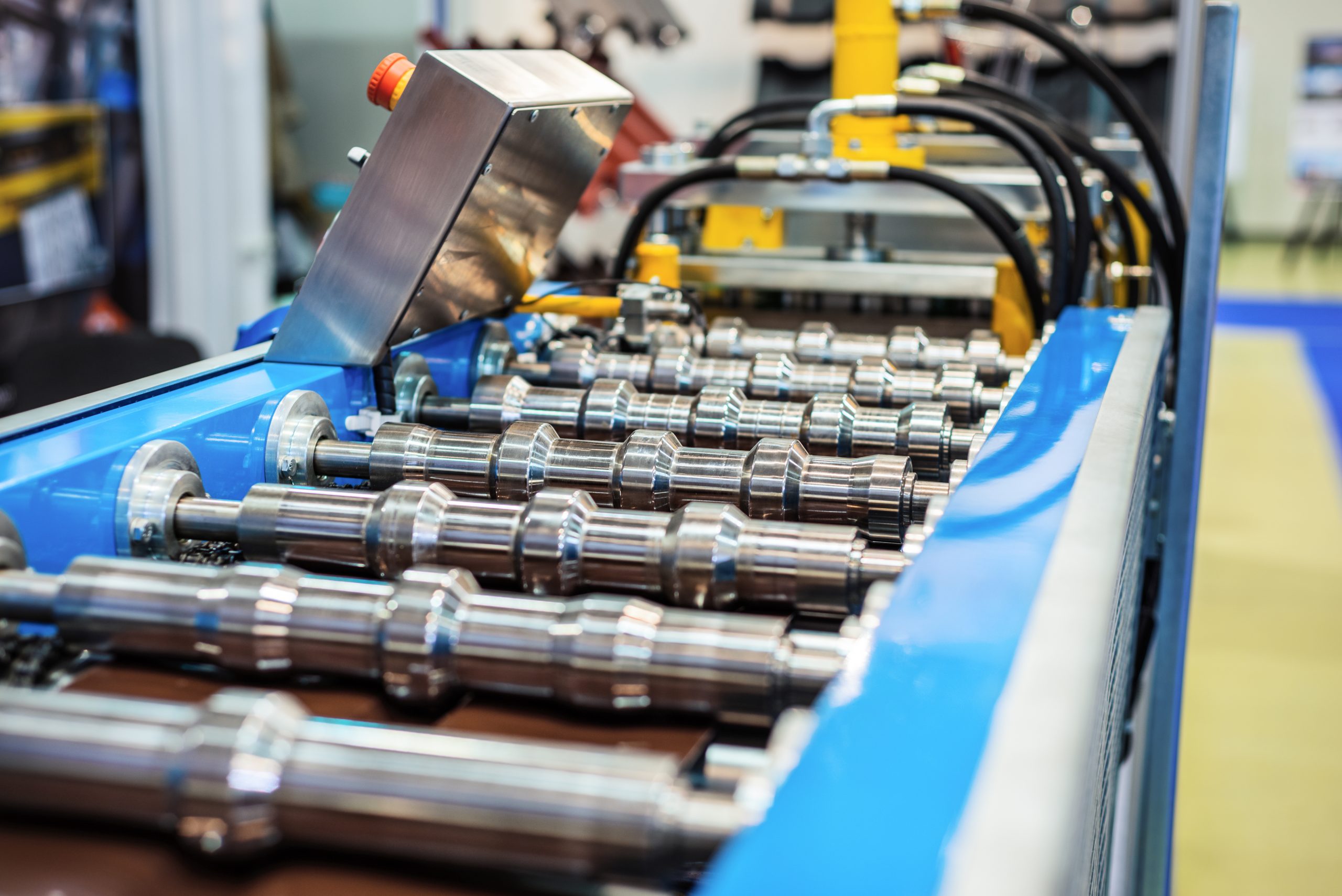

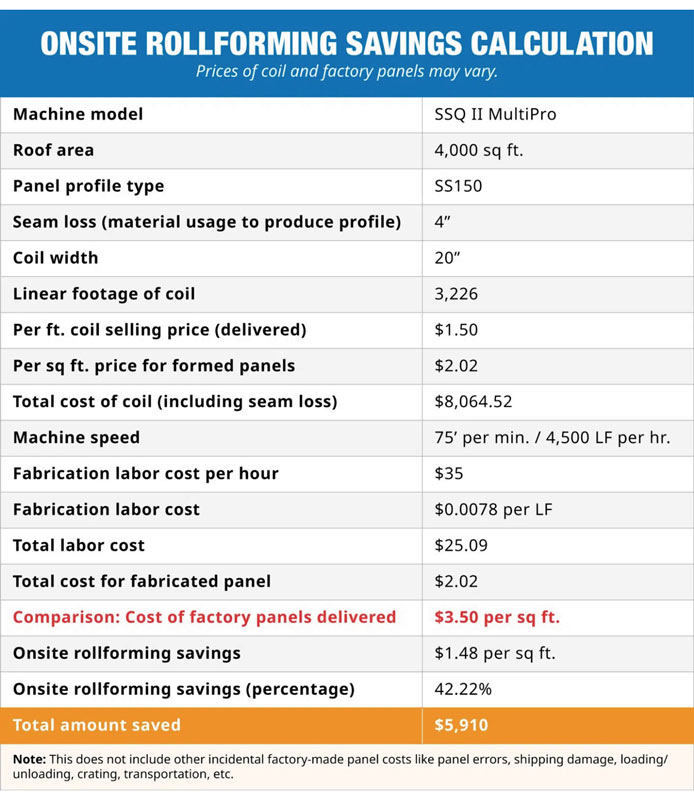

One of the most obvious advantages of owning a portable standing seam panel machine is the ability to buy metal coil and run panels yourself. In shipping and crating alone, you could save thousands of dollars on a single job. As one New Tech Machinery (NTM) machine owner explained, if you’re paying $4.00 per sq. ft. for a factory-made panel, running that same panel with your own roll former may cost you only $1.75 per sq. ft. That’s a savings of $2.25 per sq. ft. and doesn’t include what you’re saving on transporting panels to the jobsite.

Of course, savings depends on a variety of factors, including the material type and gauge, labor costs, coil price, etc. Shown above is an example using an NTM SSQ II MultiPro Roof and Wall Panel Machine, but the calculations could apply to any roll former running the same profile and dimensions.

Reduced Waste

If you’re buying factory-delivered panels, you’ll have to cut them on-site to fit the roof or wall. As a result, you’ll end up with a good deal of material landing in the recycling bin. That’s money right out of your pocket.

By roll forming panels on site, you’re able to cut panels to the exact length needed. So not only does the panel cost less when you’re roll forming it yourself, but you also have the benefit of reduced waste.

No Middleman Markup

If you purchase factory metal panels, you know the supplier’s markup eats into your profits. With a portable roll former, you control the entire production process, so you’re not paying a third party for cutting, packaging, and shipping. Also, you don’t have to wait weeks for delivery. The wait time just depends on your coil supplier, which could be a few days or a week, and possibly even less.

Labor Cost: Efficiency & Productivity

Faster Panel Production

Transporting pre-formed panels to the job site can be a logistical challenge, especially if they’re excessively long or require special handling. By producing panels on-site, your crew can form the exact panel lengths needed without having to wait on shipments or manage storage and handling.

Some contractors use a crane to raise the machine and run the panels right onto the roof. This way, there’s less manual labor and less risk of panel damage. This streamlined process translates into faster install times and keeps labor costs down.

Fewer Installation Errors

Orders aren’t always accurate, and once a shipment arrives installers might find mistakes or damaged material. Since the panels can be cut to precise lengths when you’re running them yourself, there’s less chance of error. If there is an error, you can run another panel right onsite instead of having to reorder and wait for another shipment to arrive.

Minimum Downtime

When you control the production schedule, you’re less reliant on external factors like delivery times or stock availability. This means your team can keep working instead of waiting for a delayed shipment or late delivery. Projects that run smoothly generally require fewer labor-hours overall.

Square Footage of the Job: Finding the Break-Even Point

Economies of Scale

Larger roofing projects will naturally generate bigger returns because you’re forming and installing more panels. This boosts the total profit margin as the machine’s initial cost is spread over more square feet.

However, even smaller or custom jobs benefit from on-site manufacturing. You can produce the exact panel quantity required, eliminating the need to order surplus panels “just in case.” Smaller projects will still see a solid ROI because you avoid shipping charges and manufacturer prices.

Payback Timeline

While the exact payback period depends on how often you use the machine and the size of each project, many contractors report recouping their investment within a few years. If your business regularly tackles mid- to large-size metal roofing jobs, this timeline can be even shorter.

For example, if you’ve paid $160,000 for your roll former and accessories, and you’re making $2.25 per square foot, then you’d need to run about 71,000 sq. ft. of panel to pay off the machine. That would break up to about 6,000 sq. ft. per month to pay it off in a year, or 3,000 sq. ft. per month over two years, etc. It just depends on the volume. With a few big jobs, the machine can pay for itself.

According to Todd Andrews, owner of Classic Metals in South Carolina, “It’s basically a printing press. You just put coil on top of it, turn it on, and every foot that comes out, you’re making money.”

Putting it All Together: Calculating Your ROI

When considering the investment in a portable standing seam metal roof panel machine, you’ll want to factor in:

Initial Purchase Cost

This can vary widely depending on machine size, features, and brand. A portable roll former with a standard configuration could run anywhere from $60k–$150k on average. A machine that runs one profile will cost less than one that can run seven or eight profiles, or the SSQ II MultiPro, which can run up to 16.

Coil Costs and Testing: Buying coil direct from the supplier saves on material costs per square foot. Sheffield Metals, NTM’s sister company, provides free access to testing and engineering to NTM machine owners. Likewise, other reputable suppliers offer testing to their customers.

Labor Savings

Faster production, fewer errors, and minimal downtime can quickly offset labor expenses.

Job Size & Frequency

The more standing seam projects you take on, the faster you’ll recoup your initial investment.

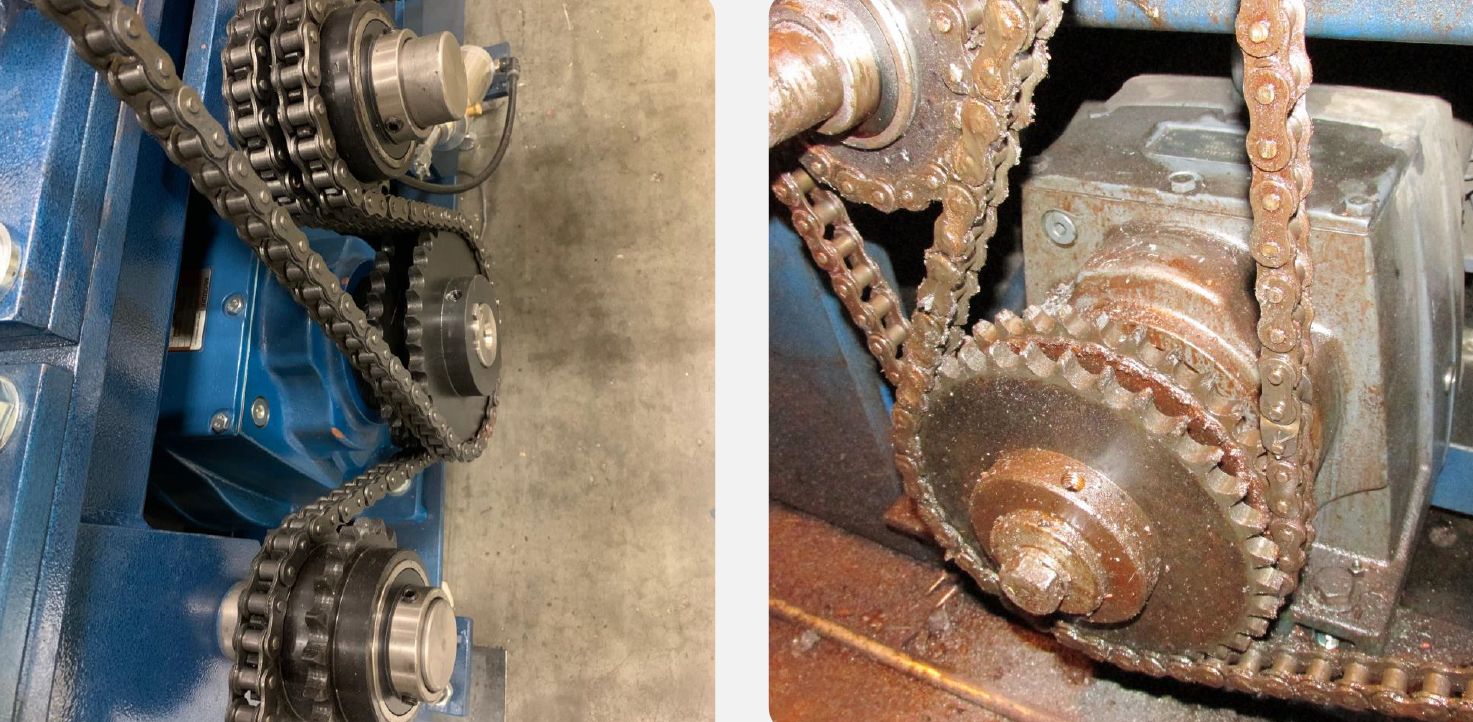

Maintenance & Training

Regular maintenance and operator training are crucial to keeping your machine running efficiently. You need to build expertise so that crews know how to operate the machine efficiently, change tooling, and make adjustments when necessary.

Considerations

You’ll need to factor in incidental costs against the ROI of owning a portable roll former. First, let’s look again at the benefits of owning your own machine:

Revenue Gained from In-House Panels

Includes any cost savings from not buying prefabricated panels and extra revenue if you supply panels to other contractors.

One longtime NTM customer provides panels to a large distributor who sends him the metal coil to run through his NTM portable roll forming machines. The NTM customer then fabricates the panels and sends them back to the manufacturer who marks up the price and sells them to contractors. This is where contractors lose money. While they could run their own panels for $1.50 per square foot, they’re instead paying a distributor $3- $5 per square foot for panels fabricated with a portable roll former.

Weigh This against Incidental Costs:

Material, Labor, & Machine Costs

The ongoing operating expenses plus the initial outlay for the machine (trailer, truck, forklift, etc.).

Machine Purchase + Maintenance Costs

You’re going to have maintenance costs, and your machine may occasionally need service. Work these expenses into your budget. Combine the machine cost, financing (if applicable), and estimated long-term upkeep. These expenses can also be included in a bank loan.

While the payoff period will vary, the combination of material savings, control over production, and labor efficiency still makes purchasing a portable machine a profitable long-term strategy.

Tax Credits

Whether you’re deducting incrementally or using the Section 179 tax benefit, you’re going to have write-offs for your machine that will further reduce the cost and put more money into your pocket.

Worth the Risk?

When you’re talking about the level of investment it takes to buy a portable roll former, you must acknowledge risk is a factor.

That said, Jim Averill built a successful metal roofing business in a Colorado resort area with just an NTM SSR MultiPro Jr., a starter machine. He’s since moved up to an SSQ II MultiPro, but that initial investment paid for itself many times over. In just the first eight weeks with his new SSQ II, he ran over 30,000 linear feet of panel. At that rate, the machine will quickly pay for itself.

A portable standing seam metal roof panel machine represents more than just a piece of equipment—it’s an investment in control over your supply chain, workforce efficiency, and the price and quality of your finished product.

By factoring in bulk material purchases, on-site production convenience, and reduced labor overhead, contractors have found that owning their own roll former significantly boosts their bottom line.