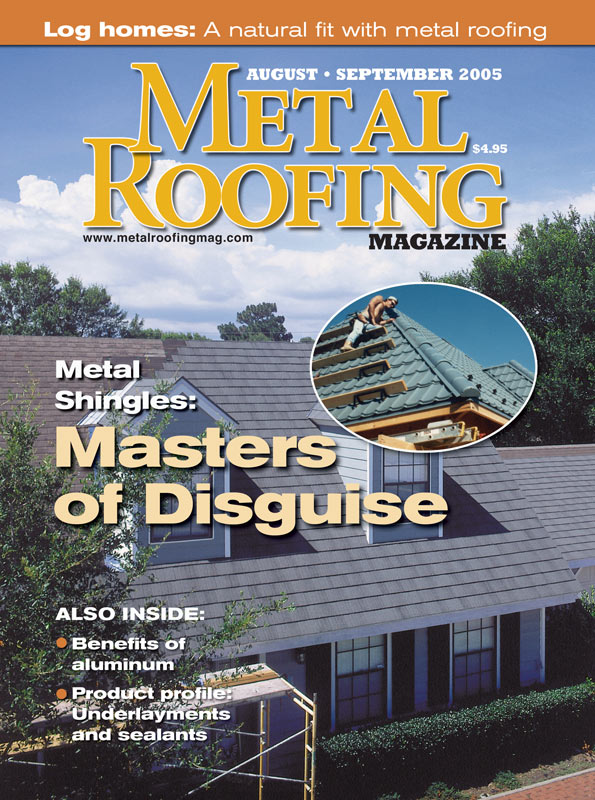

“Please Note: This article, ‘Metal Roofs are Logging on to Log Homes,’ was originally published 20 years ago, in the August/September 2005 edition of Metal Roofing Magazine. Cited people and companies mentioned may no longer be involved in the industry, and products may no longer be available.”

The building industry “has tried to get away from the term ‘log cabin’ because it suggests something small and simple,” admits Bill Keller, president of Conestoga Log Cabins, Lebanon, Pa. “Today the industry prefers the term ‘log home’ because the buildings can be pretty big.”

Conestoga is a case in point, as the 10-year-old company has manufactured log structures from $10,000 up to $250,000 in value. The company produces a wide range of pre-engineered log buildings — from small cabins for summer camps, fishing camps, and military recreation facilities; all the way to upscale log homes and even commercial applications.

“The market is growing for larger and larger log buildings,” Keller confirms, “and we’re also asked a lot of times to supply multiple buildings — as many as 100 at a time.”

Nearly all of Conestoga’s log structures, from small hunting cabins to luxurious log homes, have metal roofs. Keller says he started with asphalt shingles when the company was founded in 1995 but within three years switched to metal roofs. “They’re easy to install, look good, and offer longevity and low maintenance,” he says. “So we provide metal roofing as our standard, unless a customer specifically requests another roofing material — which isn’t often.”

Log home manufacturers and the contractors who erect the structures all agree that metal roofing is broadly accepted by homeowners. Even more than that, the impetus to install metal roofs on log homes is not coming from manufacturers and contractors who must up-sell their customers. “It’s the homeowners who are asking for metal roofs,” reports Tony Chiovare, president of Custom-Bilt Metals, Chino, Calif., a manufacturer of metal roofing and rain handling systems.

“By the time that people are ready to build a log home, they’re already familiar with metal roofing,” Chiovare continues. “They’ve seen metal roofs at home shows. And because metal roofs are becoming more common in suburbia for homes and churches, they see metal roofs when they drive down the street.”

When Custom-Bilt exhibits at log home shows, Chiovare notes, “A lot of people approach us and say they’re planning to build a log home in two or three years.” By implication, he believes, “Someone who’s ready to build a log home has already gone through a research process. They’ve looked at the internet and the homebuilding magazines. They’ve evaluated the pros and cons, and they’re aware that metal is more expensive. But they’ve made their choice. So it’s the customers who are asking for metal roofs.”

Nationwide Popularity

That assessment is shared by manufacturers and builders across the country. Chiovare estimates that in the western United States, where Custom-Bilt is active, a majority of log homes have metal roofs. Ken Gieseke, vice president of marketing for McElroy Metal, a roofing and siding manufacturer based in Bossier City, La., notes that metal roofing is “especially popular for log homes in mountainous regions” because of its appealing aesthetics and superior performance in conditions of heavy snow and wind.

In the Pacific Northwest, president Ron Foster of Foster Roofing & Construction, Oregon City, Ore., agrees that “it’s the homeowners who are requesting metal roofs.” Typical customers for log homes, he observes, are “people who have disposable income and want a second home, and older couples who don’t want to deal with maintenance problems.”

When they come to Foster, he often finds these customers have already checked out websites of metal roofing manufacturers and the Metal Roofing Alliance. “They ask for metal because they want a Class-A fire rating and they can see that the cost of metal roofing is getting close to tile and cedar shake,” he adds. Foster estimates about 75 percent of the roofs he installs on log homes are metal.

CARIBOU CREEK LOG HOMES PHOTO

DECRA ROOFING PHOTO

ATAS PHOTO

DAN PERKINS CONSTRUCTION PHOTOS

CONESTOGA LOG CABINS PHOTO

CONESTOGA LOG CABINS PHOTO

CONESTOGA LOG CABINS PHOTO

DAN PERKINS CONSTRUCTION PHOTOS

FOSTER ROOFING & CONSTRUCTION PHOTO

FOSTER ROOFING & CONSTRUCTION PHOTOS

ATAS PHOTO

The remainder, Foster reports, choose cedar shake for aesthetic reasons, or asphalt shingles for their lower cost. “But today there are metal roofing products that simulate cedar shake for homeowners who want that look,” he points out. And Chiovare of Custom-Bilt adds, “Metal shingles are starting to gain some share in the log home market. They have the traditional look of shingles but are easy to install and offer the benefits of metal.”

In the Great Lakes area of the Midwest, where Tom Sands is regional manager for Decra Roofing Systems, “a good percentage of log homes have metal roofs. People who build log homes want them for the long term. Metal roofing provides better ventilation, energy efficiency and longevity, high snow and wind loads, low maintenance, and great aesthetics. And you can even get metal roofing with the look of shingle or shake.” When owners of log homes choose other roofing materials, he says, “The main issue is cost.”

New England is an area where “by far and away, metal roofing is popular; they’ve been using metal there for a long time, starting with the old tin roofs,” reports Ed Erb, national sales manager for Everlast Roofing of Lebanon, Pa. Whether for log homes or other structures, he notes, “Homeowners ask for metal because it handles heavy snow loads and it’s good for getting the snow off the roof.”

In other areas of the Northeast and Midwest where Everlast sells its roofing products, Erb says any reluctance to install metal roofing is usually due to tradition. “The biggest reason people choose shingles is because it’s the traditional material,” he continues, “and if contractors are new to metal, they may shy away from it. Also, metal roofing initially costs about twice as much as shingles.”

But because log homes “have come a long way, from hunting cabins to upscale dwellings,” Erb says that homeowners are more willing to consider the life-cycle cost of their investment. “Metal roofs cost more upfront,” he explains, “but if you’re building an upscale log home, you’re willing to pay more so you can save money later on your home maintenance and energy costs.”

In the Great Smokies and Appalachians, regional manager Gary Rudman of Englert Inc. agrees the push for metal roofing on log homes originates with homeowners. “Manufacturers of log homes don’t furnish the roof,” he points out, “and so the choice of roofing material has to come either from the contractor or the end user. Typically, it’s the end user.”

The reason cited by Rudman is that owners often build log homes as “the last home they ever plan to live in, because it’s either their dream home or their retirement home. So they want the best.” Based in Alcoa, Tenn., he observes that about 80 percent of log homes in his region feature metal roofs and 20 percent asphalt shingles. “I haven’t seen a new cedar shake roof in the Smokies for 10 years,” he adds, “because cedar is more expensive than metal and has a poor fire rating that can affect your insurance.”

Jerry Green, vice president of Superior Products in Anchorage, Alaska, designs and builds both residential and commercial log buildings. In more than 20 years of business, he says, the company has constructed more than 1,000 log buildings throughout his state. “Less than 20 of those buildings have non-metal roofs,” he reports.

With Alaskan snow loads ranging from 50 up to 325 pounds, and winds up to 140 mph a frequent problem, “People come to me and want metal roofs,” says Green. “Only metal can handle the snow and wind, and customers like the fact that we can give them a lifetime warranty. Shingles can get damaged or be blown away and need to be replaced.” A testament to metal’s aesthetic quality, he adds, is that “our company has done log structures with metal roofs for the Alaskan cruise lines and park agencies.”

Construction Considerations

Wherever metal roofs are installed on log homes, certain construction considerations may apply. Log homes are often designed, points out Ron Foster of Foster Roofing & Construction, “with roofs that have steeper pitches than other homes.” That fact, he says, can exacerbate the usual challenge of doing roofing work on a slippery metal surface.

Foster installs snow guards on metal roofs for log homes because, he notes, “when a metal roof heats, it thaws the snow from the underside. So the snow falls off the roof all at once, like an avalanche, and could take off the gutters or maybe hand railings on a deck.”

In addition, he believes “there’s a huge difference” in the underlayment required for a log home metal roof, as compared to asphalt or cedar. “Metal roofs have lifetime warranties and will last from 50 to 70 years,” Foster says, so that standard 30-pound felt underlayment may not last as long as the roof. The felt can get brittle and crack, he suggests. In that event, condensation can occur due to temperature differences between the substrate, roof, and exterior air. Such moisture may cause older plywoods to delaminate, making it necessary to take off the roof in order to replace the plywood underneath.

For underlayment, Foster uses FelTex, a fiberglass-based product that is waterproof. “Thirty-pound felt is only water-resistant,” he remarks. His company also uses a different type of caulk on log home metal roofs, one that comes with a lifetime guarantee and is made to withstand expansion and contraction. “Metal roofs have more movement than cedar or asphalt,” he explains. “We also hide the caulking to minimize exposure to UV rays.”

By contrast, Jerry Green of Superior Products uses an upper-grade 30-pound felt for his underlayment, plus an upper-grade ice shield. “Using a higher grade of material costs a lot more, but it’s worth it,” he advises. Superior Products also puts up snow guards on its log home metal roofs “so that the snows tumbles off rather than dumps off,” he adds.

Englert’s Rudman also recommends installation of snow guards, in part because “most log homes have front porches that could be damaged if the snow dumps off the roof.” He endorses 30-pound felt as an underlayment for log home metal roofs, saying the material “works fine because the felt isn’t exposed to the sun.”

Because logs are delivered to the homesite and assembled, some homeowners worry that newly assembled logs will eventually settle and cause stresses to the roof. Rudman says he has never observed such a problem, and Green notes that his company uses dry logs so that any settling movement is very slight. “We also use custom screw jacks,” he continues, “that allow the roof to move and settle independently.” For his part, Foster believes, “Any settling is all in the walls, so that the roof settles all at once as a unit” and therefore is not subjected to stress. Manufacturers and contractors agree that log homes have a classic look that never goes out of style. But because the structures are often second homes or vacation homes, construction activity is more dependent on the economy than is the case with standard homebuilding. “But I’ll tell you what,” observes Foster. “With the inventory of log homes that have been built over the years, we’re starting to get a lot of opportunities to do re-roofing jobs for owners of log homes who want to switch to metal.”