Originally Published as: Supplier News

MFM Building Products to Celebrate 65th Anniversary

MFM Building Products, a manufacturer of a full envelope of waterproofing and weather barrier products for the building industry, will be celebrating the company’s 65th Anniversary in 2026.

MFM Building Products was founded in 1961 in Coshocton, Ohio. Initially, the company manufactured products used for wrapping underground pipe to protect from water penetration and pipe contents becoming contaminated. Over the years, MFM expanded this technology to develop sealing and waterproofing products for use within the building envelope. In July 2017, MFM became a 100% employee-owned ESOP company that still holds true to its original core values.

Today, MFM manufactures a wide array of self-adhered weather barrier products that include low-slope roofing membranes, roofing underlayments, window and door flashing tapes, multi-purpose waterproofing membranes, specialized waterproofing tapes, and HVAC duct and pipe wrap. These exterior, waterproofing membranes are self-adhering and self-sealing for ease of installation and complete waterproofing protection.

MFM products are manufactured in the United States and sold through an extensive distributor network around the globe. The company’s products qualify for the Buy American Act (BAA) and Build America Buy American Act (BABAA).

According to Tony Reis, President, “MFM can offer our customers a complete envelope of waterproofing solutions – everything from the rooftop to the foundation. This single-source option gives our customers several competitive advantages.”

Steel Dynamics Acquires New Process Steel

Steel Dynamics, Inc. has announced its completion of the acquisition of the remaining 55% equity interest in New Process Steel, L.P. (“New Process Steel” or “New Process”). New Process Steel is a metals solutions and distribution supply-chain management company headquartered in Houston, Texas, with a focus toward growing its value-added manufacturing applications.

New Process Steel is a prominent North American metal products manufacturer and supply-chain solutions provider, headquartered in Houston, Texas, with two manufacturing locations in Mexico and four manufacturing locations in the U.S., two of which are located at Steel Dynamics’ Butler, Indiana, and Columbus, Mississippi, divisions. New Process Steel was purchased in 1952 by Gene Fant, the father of New Process’ Chief Executive Officer, Richard Fant. Richard Fant has significantly grown, modernized, and diversified New Process during his over 25-year tenure as CEO. New Process employs approximately 1,275 individuals and is currently Steel Dynamics’ single largest flat roll steel customer.

Steel Dynamics has facilities located throughout the United States and in Mexico. The company operates using a circular manufacturing model, producing lower-carbon-emission, quality products with recycled scrap as the primary input. The company is one of the largest domestic steel producers and metal recyclers in North America, combined with a meaningful downstream steel fabrication platform. It is also currently investing in aluminum operations to further diversify its product offerings, with plans to supply aluminum flat rolled products with high recycled content to the countercyclical sustainable beverage can industry, in addition to the automotive and industrial sectors.

Worthington Enterprises To Acquire LSI Group

Worthington Enterprises Inc., a designer and manufacturer of brands that improve everyday life by elevating spaces and experiences, has announced it has signed a definitive agreement to acquire LSI Group, LLC (LSI) of Logansport, Indiana. LSI, which includes the brands BPD, Logan Stampings, LSI Metal Fabrication and Roof Hugger®, is one of the largest U.S. manufacturers of standing seam metal roof clips and retrofit components in the commercial metal roof market.

Worthington Enterprises plans to purchase LSI Group for approximately $205 million with cash on hand and borrowings under the company’s revolving credit facility. The transaction is expected to close in January 2026, subject to regulatory approval and other customary closing conditions.

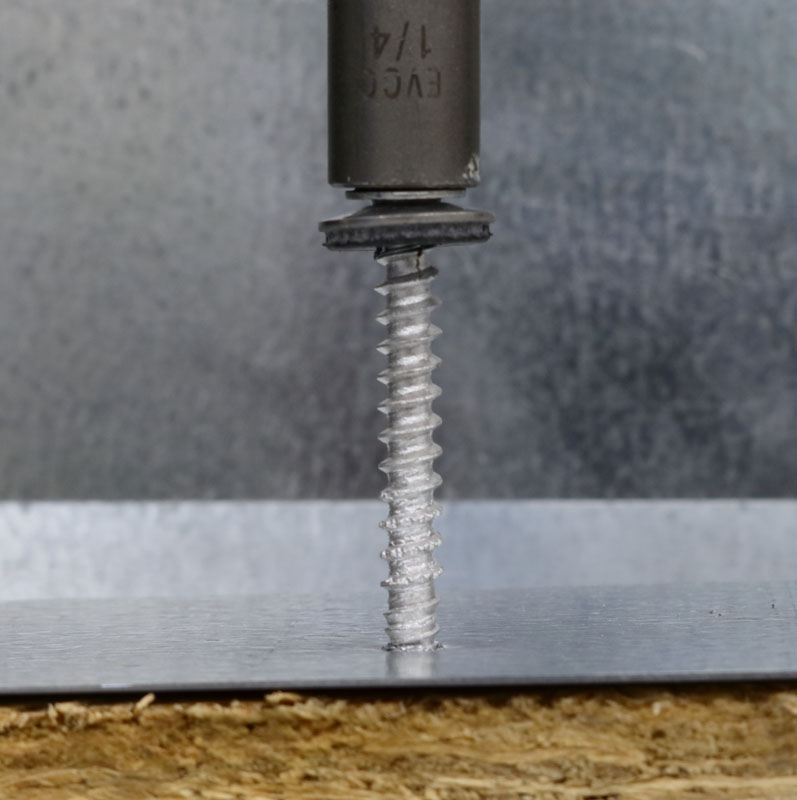

Demand for resilient, energy-efficient and durable roofing systems is expected to continue growing as building owners prioritize stronger, code-compliant structures in response to evolving weather patterns and manage rising energy costs and aging commercial building infrastructure, especially as roofs built during the construction boom of the early 2000s are now reaching the end of their service life. Common applications are industrial and manufacturing facilities, retail buildings, academic and municipal structures, hospitality, data centers, and recreation and mixed-use spaces. Standing seam metal roof clips, which act as concealed anchors, secure each metal roof panel to the underlying roof substrate. (A new 10,000-square-foot roof requires approximately 8,000-10,000 metal roof clips.)

LSI serves the retrofit market with the Roof Hugger brand of metal sub-purlins used to attach a new roof on top of an existing roof. Compared to full replacements, retrofitting with a metal roof lowers installation costs, improves energy efficiency, enhances code compliance, minimizes disruption during installation and increases sustainability.

LSI has two manufacturing locations in Logansport where it was founded in 1968 as Logan Stampings. Robert Baker, owner and president, LSI Group, LLC, purchased Logan Stampings in 2004 and grew the business through innovation, acquisition and prioritizing relationships. He will continue as a leader of the LSI business as part of Worthington Enterprises.

Combilift’s 100,000th Forklift Raises €100,000 for Global Children’s Charity

Global materials handling provider Combilift has celebrated a major manufacturing milestone by transforming its 100,000th forklift into a powerful force for good, raising and donating €100,000 (US $117,745) to the United Nations International Children’s Emergency Fund to support children in crisis worldwide.

To mark the production of its 100,000th forklift, Combilift launched its largest-ever worldwide competition, offering the exclusive 100,000th “Golden Prize” multidirectional Combi-CBE. All proceeds raised were donated to UNICEF Ireland’s Children’s Emergency Fund.

The campaign generated €56,500 (US $66,526) in ticket sales, and at a check presentation ceremony, Combilift announced it had topped up the total contribution to an impressive €100,000, underlining the company’s long-standing commitment to corporate social responsibility.

Speaking at the handover, Combilift CEO and Co-Founder Martin McVicar said: “This campaign was designed not only to celebrate a major manufacturing achievement for Combilift, but also to make a meaningful difference beyond the factory floor. By supporting UNICEF, we are supporting one of the world’s most effective humanitarian organisations and helping children who need it most.”

The check was formally presented by Martin McVicar to Owen Buckley, UNICEF Ireland’s Head of Corporate Partnerships, and Michaela Plunkett, Business Development Manager, in Monaghan.

Owen Buckley welcomed the donation, saying: “As we enter the winter season, our priority is ensuring children affected by war and natural disasters have access to warm clothing, safe shelter and continued education. This generous contribution from Combilift will help UNICEF respond quickly to urgent needs.”

The winning ticket was purchased by Kareen Farrell, who travelled to Combilift’s headquarters in Monaghan to receive the one-of-a-kind 100,000th Combi-CBE “Golden Forklift.”

Reacting to her win, Kareen Farrell said: “I was absolutely delighted when I heard I had won, as I’m never lucky. My dad shared the competition details and bought a ticket to support UNICEF because it’s a children’s charity that helps children all over the world, so winning the forklift was an incredible bonus.”

The Golden Forklift was first unveiled at the IMHX Exhibition in the UK before embarking on a European trade show tour, attracting strong international interest and reflecting Combilift’s global customer base and shared commitment to positive social impact.

RefrigiWear® Supports Western Alaska Flood Recovery with Gear Donation

RefrigiWear, a manufacturer of insulated industrial workwear and personal protective equipment for extreme cold, is supporting recovery efforts in Western Alaska following the devastation caused by Typhoon Halong. Typhoon Halong left widespread flooding across Alaska’s western coastline, destroying homes and displacing hundreds of families just weeks before freezing temperatures arrived. With cleanup underway and recovery crews facing months of difficult work, properly insulated gear is vital to ensure safety and comfort in harsh conditions.

The company has donated more than $18,000 in high-performance insulated gear to help protect recovery workers and displaced families as winter conditions set in. RefrigiWear’s contribution is being coordinated through 6th Avenue Outfitters, a Native Alaskan-owned cooperative in Anchorage that is leading the on-the-ground effort to collect, prepare, and distribute critical cold-weather supplies in partnership with the Alaska Federation of Natives (AFN) and the Association of Village Council Presidents (AVCP).

6th Avenue Outfitters has organized a $30,000 donation of outdoor clothing and equipment, including $25,000 in winter boots and jackets, to assist families and workers displaced by the storm. RefrigiWear’s gear donation adds to that effort, helping recovery teams stay safe and warm while they rebuild flood-damaged homes and infrastructure across the Yukon–Kuskokwim Delta and other coastal communities.

The first shipment of gear is being distributed through 6th Avenue Outfitters and AVCP to recovery crews in Western Alaska. RefrigiWear’s donation has also been sent to Calista Corporation to support additional workers assisting with cleanup and rebuilding efforts throughout the region. All of the donated gear was sized specifically for the individual workers receiving it, ensuring proper fit and full protection in severe winter conditions. AVCP was selected as a partner because of its established network of 56 village councils throughout the Yukon–Kuskokwim Delta. This network will help donated supplies reach the communities most directly impacted by the storm quickly and efficiently.

Additional deliveries are planned as families are relocated to Bethel, Fairbanks, and Anchorage. In Anchorage, several hundred displaced residents have already received more than $5,000 in donated gloves, hats, and neck warmers through 6th Avenue Outfitters’ relief center.

Leigh Stadelmeier, Vice President of B2B Outdoor Sales for RefrigiWear, says the company is proud to play a part in protecting those doing difficult recovery work. “In disaster recovery, the work is demanding, and the conditions are unforgiving,” explains Stadelmeier. “Our mission is to protect those who show up to do the hardest work, whether they are rebuilding their own community or helping their neighbors recover. Partnering with 6th Avenue Outfitters allows us to get this gear directly to the people who need it most.”

CMG Announces New Location in Dallas-Fort Worth

Coated Metals Group (CMG), a manufacturer of high-quality metal coils, sheets, and roofing accessories, has announced the opening of its 13th location, a new stocking and distribution hub in the Dallas-Fort Worth (DFW) area.

This opening comes on the heels of CMG’s recent expansion into Austin, which has been met with enthusiasm and strong demand from contractors, architects, and distributors throughout Central Texas. Recognizing the region’s rapid growth and robust metal roofing market, CMG continues its commitment to geographic expansion that supports local inventory, faster delivery times, and stronger customer partnerships.

“Texas has become one of the most dynamic markets for metal roofing,” said Matt Johannsen, Director of Strategic Expansion. “With a growing population, increased construction activity, and a strong interest in durable, high-performance materials, the Dallas-Fort Worth area is a natural next step in CMG’s expansion strategy.”

The DFW branch will be led by Graham Jeske, General Manager, and Brock Baker, Outside Sales Representative. Both bring years of experience with Coated Metals Group and the metal roofing industry, ensuring customers receive knowledgeable service, dependable lead times, and the industry expertise CMG is known for.

As a stocking distribution center, the new facility will provide locally available coil, flat sheets, and roofing accessories, enabling faster turnaround times and reduced freight costs for customers across North Texas and surrounding regions.

“Our focus has always been to meet our customers where they are,” added Matt. “By investing in key markets like Dallas-Fort Worth, we’re not only expanding our footprint but strengthening the service and support our customers rely on.”

Finalist Teams Announced for Roofing Alliance 12th Annual Student Competition

The Roofing Alliance has announced the four finalist teams selected to compete in its 12th Annual Construction Management Student Competition. The teams will present their project proposals live during the International Roofing Expo® (IRE) on Wednesday, January 21, 2026, beginning at 8 a.m. in room W211–W212 at the Las Vegas Convention Center, where they will be evaluated by a panel of industry judges.

The schools participating in the competition are:

- Auburn University – Team members: Madi Goodwin, Heather Henderson, Patrick Johnson, Graham Roh (team captain) and Ashwin Varadhan; faculty advisor: Dr. Kenneth Sands; team mentor: Paige Harvill, Nations Roof

- Clemson University – Team members: Drake Hamlin, Sean Linnane, Remi Nguyen (team captain), Ben Reynolds and Grant Thomas; faculty advisor: Dr. Dhaval Gajjar; team mentor: Will Fort, Bone Dry Roofing

- Colorado State University – Team members: Brandon Gallis (team captain), Kathleen Henneuse, Thomas Parrott and Rafael Serrano-Talavera; faculty advisor: Professor Nick Rubino; team mentor: Kent Nelson, Front Range Roofing Systems

- University of Florida – Team members: Nicholas Fredette, Tyler Isaacson, Sophia Petrandis, Rylee Rauktis (team captain) and Christian Walker; faculty advisor: Professor James Sullivan; team mentor: Caleb Stauss, Big D Roofing

The competition project, provided by Commercial Roofers Inc., Las Vegas, challenges teams to create a comprehensive bid proposal for the Cannery Casino and Hotel. Teams researched the chosen project, submitted a qualified bid package proposal and will provide an oral presentation to illustrate their roofing, project management, estimating and safety knowledge. The winning teams and presenters will be recognized on stage during the NRCA Industry Awards and Reception on January 21 from 5-7:00 p.m.

McElroy Metal Announces Leadership Transition

After an extraordinary 36-year career, Jeff Harrington will be retiring from McElroy Metal effective January 30, 2026.

Jeff began his journey with McElroy Metal Mill in 1989, and over the years, he has served in numerous positions across multiple locations. His deep knowledge of McElroy Metal’s operations, commitment to excellence, and willingness to take on any challenge have made him an invaluable leader and a respected colleague. Known for his enthusiasm, optimism, and dedication to his team, Jeff’s positive spirit has been a driving force in creating a culture of collaboration and pride across the company. “Jeff’s dedication and steady leadership have played a significant role in our company’s success, and his legacy will be felt for years to come,” said Amanda Haskins, Chief Financial Officer.

McElroy Metal has announced that Mark Rollins will assume the role of General Manager of Service Centers, replacing Jeff upon his retirement. Mark began his career with McElroy Metal Mill in 1996 and, like Jeff, has held many roles across several locations. With a long and successful history in Operations and Service Centers, Mark brings a wealth of experience, insight, and leadership to his new role. Haskins added, “We are confident that under Mark’s guidance, the Service Centers will continue to grow and thrive.”

McElroy Metal’s Service Center Division operates a nationwide network of 29 stocking locations that provide contractors, architects, and homeowners with convenient access to metal roofing, siding, trim, metal building components, and accessories.