While fasteners are the least expensive item on a metal roof, they are also very important. This small part is crucial for maintaining structural integrity and water tightness. Not only is the correct type of fastener necessary, but the spacing and pattern of the fasteners are also essential to get right.

Fastener placement on a roof depends on several key factors—including the strength of the roof panel, its position on the structure, and the wind loads it’s expected to endure. Because of these variables, manufacturers typically provide fastening guidelines tailored to their panel designs and backed by how they completed relevant testing. Understanding successful metal roofing installation also involves examining the role of the purlin-bearing leg and side lap sealant. Let’s take a closer look at how each of these elements contributes to proper fastening.

Fastener Spacing

The spacing of the fasteners that hold the roof in place can directly determine its load-bearing capacity and resistance to weather and environmental stress, such as snow and wind loads.

While it is logical to think that simply tighter spacing equals more strength and security, it is often not the case in the field. Smaller distances between fasteners are not always the most economical or efficient choice. You do not want to make more holes than necessary in your panels.

When selecting a fastener pattern, it is essential to follow manufacturer specifications to avoid compromising weather tightness or installation failures. It also helps to remain within warranty specifications. Courtesy of MCA.

When determining fastener spacing, it is essential to consider the type of roof you have, whether it is a gable, hip, single-sloped, or curved shape.

The correct fastener pattern could be the make-or-break factor under wind, snow, and rain loads. Photo courtesy of The Metal Construction Association (MCA)

While not always true, steel purlins tend to have a firmer grip than other materials, providing a secure anchor point that allows for wider fastener spacing. Photo courtesy of Triangle Fastener Corp.

Six Factors that Determine Spacing

1 Panel Thickness and Material Type

Metal roofing panels come in different thicknesses or gauges, which impacts the fastener spacing requirements. Thinner panels have less strength to resist bending and require tighter support spacing to prevent buckling, which indirectly increases fastener count. A steel panel will have greater strength than an aluminum panel of the same profile and thickness.

2 Panel Profile

Deeper panel profiles have greater bending and deflection resistance and can span farther than shallower panel profiles. Also, panel profiles with more major ribs tend to be stronger than panel profiles with fewer major ribs.

3 Substrate Type

Roofing substrates for metal roofing attachments can include structural purlins, wood, or even concrete. Each substrate offers distinct physical properties that ultimately impact the fastener pullout strength and spacing. While not always true, steel purlins tend to have a firmer grip than other materials, providing a secure anchor point that allows for wider fastener spacing.

4 Roof Shape

When determining fastener spacing, it is essential to consider the type of roof you have, whether it is a gable, hip, single-sloped, or curved shape. The slope and shape of the roof directly affect wind uplift and snow loads, which in turn impact the recommended fastener spacing. Roof slope, also known as pitch, influences fastener spacings due to differences in how environmental forces, like wind, react to low versus high-sloped roofing systems. This is especially true for areas that experience greater uplift, such as eaves and ridges.

5 Height of the Eave

Wind imposes a greater load on taller buildings than on shorter buildings. Taller buildings are exposed to winds from a higher elevation. Winds from higher up are less affected by the surface roughness surrounding the building. It’s important to consider height when determining fastener spacing.

6 Geographical Location

Mountainous locations often experience higher wind speeds and snow loads, while coastal locations are more susceptible to hurricanes and onshore winds. Buildings in open grasslands experience greater wind effects than buildings in areas with surrounding hills, buildings, and trees. Greater surface roughness tends to slow the wind and mitigate its impact. These factors are important considerations when installing exposed fastened panels.

Fastener Patterns

Fastener patterns indicate the specific placement of fasteners on metal roofing panels and siding to resist pull-out forces, diaphragm strength, and weather tightness. The correct fastener pattern could be the make-or-break factor under wind, snow, and rain loads.

Since different areas of the roof are subjected to varying forces, it is advisable to use a combination of fastener patterns to ensure optimal performance. This includes sealing the edge conditions and compressing the sealants and closures so that the system maintains its integrity against water infiltration. Here are a few guidelines:

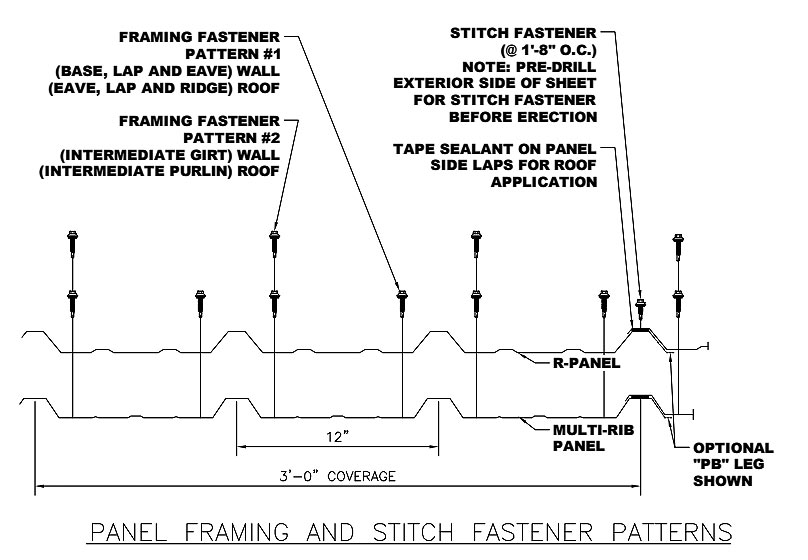

1 Use Framing Fasteners at Panel Ends

The framing fastener is essential for securing roof panels to the roof substructure. The placement, number, and spacing of these fasteners are determined by the specific panel style and the manufacturer’s recommendations. Many manufacturers include a purlin bearing leg on their R-panel products. This purlin-bearing leg (PB) is an extended lip on one side of the panel that sits on the roof purlin, enhancing support, structural integrity, and the panel’s overlap. When installing the fasteners, the PB leg ensures that the leading-edge rib of a metal panel remains aligned and stable, preventing it from bending or shifting downward (also known as ducking out).

2 Use Stitch Fasteners To Connect Panels To One Another

Unlike framing fasteners, stitch fasteners primarily aim to secure two pieces of metal together without penetrating the substructure. Stitch fasteners are often required in open-framed buildings to ensure diaphragm strength. They also help keep the sealant compressed. Common locations for stitch fasteners include panel sidelaps and trim attachments.

3 Use Sealant to Minimize Leakage

To minimize the risk of leaks, it is standard practice to apply a sealant to the exposed fastened panel sidelaps when installed on slopes less than 3:12, owing to capillary action. An example of why the sealant is necessary occurs when you place two microscope slides together with a small amount of moisture between them. You’ll observe that water rises between the two surfaces. This effect is known as capillary action. Similarly, this phenomenon allows water to seep into the gaps between panels in construction.

If a storm creates an internal suction (lower pressure) in a building as compared to the external pressure, that pressure difference can draw water into the building along each side lap that does not contain sealant.

The diagram shown for R-Panel and Multi-Rib panels illustrates the manufacturer’s recommended fastener spacing. It’s essential to obtain this information from your panel manufacturer before starting the installation.

Obtain an Engineering Consultation

The panel manufacturer often has a standard recommended pattern, and building codes prescribe patterns for areas with high-wind and seismic activity. Structural engineers and architects could be considered important players in fastener patterns. You will often need to consult a licensed structural engineer to accurately calculate spacing to avoid legal liability for structural failure or panel blow-off.

According to Josh Krohn, Engineering Services Manager at Triangle Fastener Corporation, the two pieces of information that would interest structural engineers and panel manufacturers that the fastener suppliers may provide are the thread size and head size of the fasteners, as well as the pull-out and pull-over values. The structural engineer will essentially take the load they expect the roof panel to bear and divide it by the pull-out or pull-over values that the fasteners can resist, to determine the number of fasteners needed for a particular panel.

A Factor of Safety typically reduces the ultimate capacity of a fastener to an allowable capacity. The purpose of using a Factor of Safety is to ensure that if the maximum expected load occurs, the fastener retains a reserve of resistance to prevent failure.

Utilization of Section Properties and Load Tables

Your manufacturer will provide section properties and load tables, including information on the maximum pressure a panel can withstand under specific load conditions. As a contractor, you should use these resources, along with your engineer, to determine the best fastener spacing.

Correct spacing of fasteners, proper patterns, and components, such as PBR legs and side lap sealant, are essential for a successful roof installation project. These elements help prevent structural failures and reduce the risk of panel blow-off. For the best outcomes, always consult the manufacturer’s specifications and certified professionals.