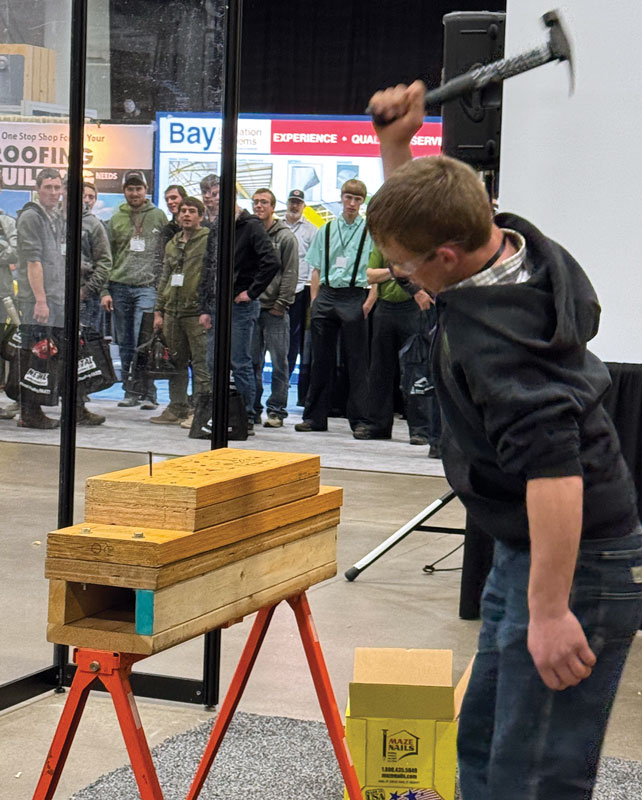

Founded in 1848, Maze Company is celebrating 176 Years in business in 2024! There’s only one way to achieve that kind of longevity in the building materials industry…and that is with UNSURPASSED QUALITY. In addition, Maze is one of the very few remaining mills committed to manufacturing nails in the United States of America. Located in Peru, Illinois — Maze is preserving valued manufacturing jobs right here at home.

Maze had worked closely with the post-frame construction industry for many decades. Every facet of a Maze Nail is designed with the builder in mind — with dozens of improvements due to direct feedback from contractors.

HIGH CARBON STEEL

Nails are made from different grades of carbon steel. A short roofing nail does not need the same high grade of steel required by an 8” ring shank pole barn nail. The Maze engineers worked closely with their steel suppliers to ensure that builders would not be high in the air — nailing purlins to trusses — only to have bending and snapping nail frustrations.

THREADED NAILS

Maze Co. (and their old division known as Independent Nail) invented spiral shank nails in 1930 and then ring shank nails in 1934. The concern at the time was that smooth shank nails tended to back out — and couldn’t give the high holding power needed when buildings racked and twisted as the lumber dried — or when the building was challenged by high winds. Many different thread forms were tried and tested — and in the end — ring shank was the winner.

RUST PROTECTION

Starting in 1916, Maze has been using the Hot-Dip Galvanizing process for putting a thick, uniform coating of zinc on nails for the ultimate in corrosion-protection. This was done by hand until 1955 — at which time Maze created the first automated process for actually DOUBLE Dipping nails to ensure a more uniform coating. Our competitors tried every galvanizing and coating method they could think of — but the Double Hot-Dipping quality was not duplicated. Even the clever foreigners have pulled out their hair trying to emulate the Maze method. Bottom line — the MADE IN USA Maze STORMGUARD® coating works the best for ensuring no rust in treated wood and all other parts of post frame buildings nationwide.

AVAILABILITY AND DELIVERY

Top-quality building products are only truly valuable if you can get them — and get them fast. The Maze Nail plant prides itself on keeping extraordinary stocks of Hot-Dipped Post Frame nails, Rubber and Silicone washer nails, Gutter spikes, Connector nails, Oil-Quench Hardened nails (and many other types!) IN STOCK FOR IMMEDIATE SHIPMENT. Even during the pandemic — Maze kept up with the industry demand — so that nails would be the least of your worries.

The Maze family continues to run the operations — with the fifth and sixth generations actively involved with the company. President Roelif Loveland acknowledges, “It is because of our customers’ great support and enthusiasm for our carefully engineered and manufactured line of 100% Made in the USA nails that we’re still in business today.” MOH